Laser beam machining is a high-power technique for providing high accuracy in the manufacturing process with high speed and reliability. This technique uses concentrated laser beams for cutting and modification of materials. It is used for different industries, such as aviation and electronics, for providing good results with low material wastage.

Here we will cover details for leader beam machining working features and advantages with some limitations.

What Is Laser Beam Machining?

- Laser beam machining, or LBM, is a type of machining process that works with heat directed from the laser beam. This process involved the use of thermal energy for removing materials from metal and non-metal surfaces.

- High frequency in this process strikes the surface in heated melting and vaporizing materials as a result of photon collisions.

- Laser beam machining is good to use for brittle materials that have low conductivity and is also used for different materials.

- The laser beam matching process is also performed on galls without surface melting. With photosensitive glass, a laser varies the chemical composition of the glass helps provide selective etching.

- Glass is also called photomachinable glass. The main feature of photomachineable glass is that it produces accurate vertical walls and native galls, best suited for biological uses like substrates for genetic analysis.

Working Principle of Laser Beam Machining

- The basic principle of laser material is to produce a laser beam directed at materials. The concentrated energy of a laser applies heat to materials to their melting point or vaporization point, resulting in accurate cutting.

- This process is performed with the use of the laws of optics and thermodynamics, through effective energy transfer to materials.

History of Laser Beam Machining

- The laser beam matching is an important innovation in the manufacturing industry. The first time the laser was introduced was in 1917 by Albert Einstein, but in 1960 first operational laser was made by Theodore H. Maiman.

- This invention helps to improve the laser beam machining process that helps to make different adaptations and advancements and makes material processing effective.

How Does Laser Beam Machining Work?

Laser beam machining is a modern manufacturing process that uses the concentrated power of a laser beam for getting accurate removal of materials. The working process involved for this manufacturing technique involves some steps that are explained here.

Laser Generation:

- This process first is to make the laser beam different devices, such as CO₂ lasers; current excites gas mixtures, and as a result, laser light is generated. Diode process lights in fiber lasers are amplified over fiber optics.

Beam Manipulation:

- After beam generation, it was manipulated with the use of lenses and mirrors. This manipulation of the laser beam is important for getting the required machining result on the workpiece.

Interaction:

- In this step laser beam collided with the material, where high energy density resulted in materials for heating, melting, and vaporizing. That interaction is regulated with getting accurate cutting.

Process Control:

- • The latest computer system handles the complete process and provides accurate results. In this process system controller laser direction, power, and work for different material types and machine process demands.

Types of Lasers

CO2 Lasers

- • The CO₂ laser is a commonly used type of laser in machining processes that has good power and reliable features. It normally operates for different kilowatt values and is best for cutting different materials such as metals, glass, and plastic.

- Their working is based on a gas mixture for generating a laser beam that is applied to the working component of machining.

Nd:YAG Lasers

This type of laser releases light in the infrared region of the spectrum. These lasers are used for high power and have features for producing continuous and pulsed modes and are good where deep penetration is needed with high accuracy, like drilling and cutting in the aviation and automotive industries.

Fiber Lasers

Fiber laser cutting is the latest technique for laser cutting. The fiber laser cutter produces laser light through diodes and amplifies light with the use of a fiber optic medium.

It has a 1070nm wavelength range and provides high efficiency and a quality beam. Fiber lasers are used since they have highly accurate machining processes, especially for cutting and engraving circuits.

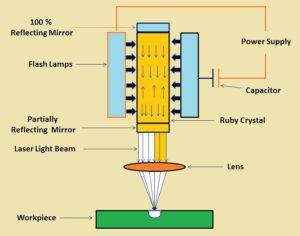

Components of a Laser Beam Machining System

Power Source

- High voltage is used for laser generation. Power source connected with circuit for electron excitation. As a result of the power supplied, electrons are excited and now ready for function.

Flash Lamps

- Flash lamps emitted coherent and white light for a short time.

Capacitor

- The main function of a capacitor is to store and release charge. In laser machining capacitor is working at the time of theflashing process.

Reflecting Mirror

- The reflecting mirror is used for light reflection on the working component. It has inner and external types.

Lens

- Lenses are used for vision function, and they provide a larger-sized image so they can perform proper function on working material.

Workpiece

- is the component where the laser matching process is performed.

Components of a Laser Beam Machining System

Power Source

- High voltage is used for laser generation. Power source connected with circuit for electron excitation. As a result of the power supplied, electrons are excited and now ready for function.

Flash Lamps

- Flash lamps emitted coherent and white light for a short time.

Capacitor

- The main function of a capacitor is to store and release charge. In laser machining capacitor is working at the time of the flashing process.

Reflecting Mirror

- The reflecting mirror is used for light reflection on the working component. It has inner and external types.

Lens

- Lenses are used for vision function, and they provide a larger-sized image so you can perform proper functions on working material.

Workpiece

- is the component where the laser matching process is performed.

Material Machined by Laser Beam

Metals

- Stainless steel:

- It has been used since it has corrosion resistance and durability features

- Aluminum:

- It is low weight and best suited for the automobile industry.

- Titanium:

- It as a high strength-to-weight ratio so part of the aviation industry

- Copper:

- It has good conductivity and is part of electrical components.

- Brass:

- It is a mixture of copper and zinc and part of plumbing.

Non-metals

- Plastics:

- ABS, acrylic and polycarbonate come with certain features for different uses.

- Ceramics:

- It comes with the latest ceramic that used for high-temperature conditions.

- Glass:

- It comes with soda lime glass for complicated cutting and etching.

- Composites:

- It is used for carbon fiber reinforced plastics that used in the aerospace industry

- Wood:

- It is used for complicated circuits in décor

Special Materials

- Photomachinable glass:

- It is employed for microfluidic circuits.

- rubber:

- It is used for gaskets and different industries

- Foam:

- It comes with polyurethane foam used of insulation and packaging.

- Textiles:

- Itis used in the textile industry

Laser vs. Electron Beam Machining

- Laser machining operates with the use of concentrated light energy, and electron beam machining uses a stream of electrons.

- Laser machines are important and versatile and are operated for different materials, and electron beam machining is highly specialized and needs a vacuum for working.

- Laser matching is used for cutting and drilling, and electron beams are used for welding and micro-machining applications.

Laser Beam Machining vs. Laser Cutting

Laser Beam Machining

- This technique employs material removal with the use of vaporization, also used for complicated and highly accurate machining operations.

- Its main working is for material shaping with high-speed processes and uses larger-scale operations.

Limitations of Laser Beam Machining

- The heat generated during the laser cutting process has an effect on material features and needed control processes.

- Some metals, liker, are not easy to cut with this process since they have reflective results.

- It needed proper maintenance and calibration for good working.

- It needed high costs for laser-based projects.

- Some material used for this process releases laser energy that is absorbed and reduces efficiency.

- High-power laser manufacturing processes are high cost.

FAQ

Does the laser beam machine process vaporize material?

- During laser beam machining, material vaporizes at the time of the material removal process. If a high-energy laser beam is applied to a working component, high heat is produced and different variations for material. This process provides accurate cutting and drilling without making connections between tools and working components, reducing wastage.

Is laser beam machine maintenance needed?

- The regular maintenance used for machines is cleaning of lenses and inspection of cooling circuits. If you have accurate, it provides good performance and a longer machining working life.

What safety parameters are for using a laser beam machine?

- Use protective glasses, and work according to the rules for the laser handling process, and provide ventilation for controlling inhaling fumes. Laser machines also have barriers to reduce any exposure.

Which workpiece is not used for laser-beam machining?

- Laser machining uses different materials but is not good for some materials like copper and aluminum that reflect laser beams. In result, damage to laser devices. Thick materials that have high melting points, like steel not cut in an effective way since they have low heat dissipation.

What are the laser beam machining techniques?

- LBM is a subtractive process that operates with thermal energy produced with laser beams. At the time of the machining process, a high-energy laser beam collides with the working components and removes the working components through vaporization and melting.

What are the uses of laser machining?

- It is used in aviation, steel, and the medical field for accurate machining of complicated components. Laser welding is a benefit that can weld at 100 mm/s. .

What are the benefits and limitations of the laser beam machining process?

- Its benefits are cutting through any materials and not needing tooling charges. It does not face wearing out of the surface and operates with highly precise results.

- The limitation is that the laser beam needed high costs for maintenance with high capital costs.

How does a laser beam work?

- The laser beam is produced when electrons in atoms of optical materials such as glass, crystal, or gas absorb energy in light form. As a result of this energy, electrons are excited from lower orbits to high-energy states around the nucleus.

What materials are machined by using a laser beam?

- Laser beams are used for cutting, machining, etching, and welding and also for heating processes.