Retaining rings, also called snap rings, are metallic fasteners connected in the groove of a shaft or bore for assembly retaining. This component kept parts at a given position with the use of a compact, low-weight structure that needed a low matching process compared to other fastening methods. Here we will cover details for retaining rings and features that help to use them for different applications.

What are retaining rings?

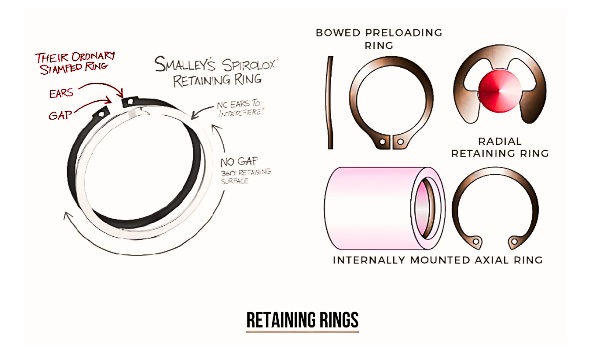

- Retaining rings, also called snap rings, are circle-like fasteners. Their design makes a shoulder on the shaft that holds a certain component in its position.

- These modules come with different designs, like untapered and tapered. Tapered retaining rings come with a tapered structure. They have a narrow design towards the opening, and untapered retaining rings come with an over-structured thickness.

- They also come with spiral retaining ring types that are like untapered retaining rings that come with untapped designs and similar thickness values.

- Spiral retainer rings come with closed circles and untapered retainer rings.

Retaining Rings Working

- Retaining comes in different designs, and all operate in the same way. Put the retaining ring on the shaft or inner side of the bore.

- Retaining rings are put about the shaft. Check that the shaft comes with a precut groove; put the retaining ring in that groove to hold the assembly in that position.

- Retaining rings are also put in bores, that is, openings. As retaining rings come in an accurate size, they fit the inner side of the groove of the bore and hold the assembly.

- The structure of retaining rings is strong and made of stainless steel alloys. In any design, tapered, untapered, or spiral retaining rings come with a circular design that handles shafts and bores.

Types of Retaining Rings

Tapered section retaining rings

- Tapered section retaining rings have a symmetrically decreasing design from the middle to the free end and come with a circular shape at the time of contraction and expansion in limited value.

- It makes a connection with the groove over the complete design of the ring. These rings are connected in a horizontal way over the middle point of the axis. According to the size of the rings that are made in two methods, in small rings, dies and stamping are used on presses from steel coils.

- For larger rings, the creation of wires, where rectangular wire is coiled in the shape of a ring.

Axially assembled

- Axially assembled retaining rings are connected in machined grooves in the housing. This ring is made with lug holes in lugs of both axial inner and external retaining rings that are used for connection and removal with the use of pliers.

- It is also configured in a cone mounting design that helps to make assembly simple, so it is used in the automotive industry.

Inverted retaining rings

- Inverted retaining rings are axially varied assembled rings that come with lug holes inverted for fitting in the lower part of the groove. Inverting lugs provide high clearance on the shaft and make a smooth shoulder that handles bearings and components with larger corner radii or chamfers.

Beveled retaining rings

- This ring comes with a 15-degree angle edge. That handle helps rings to wedge between grooves and retain components until they do not move further, for effective locking. Use a cork in the bottle; configure the cork in the opening until it wedges into the opening.

- It also occurs for installing beveled retaining rings. The ring is wedged in position between the groove wall and the retained component. As a result, make rigid end-play take-up.

Radially assemble

- This type of retaining ring is connected externally to machined grooves on the shaft. These rings do not have lug holes and are connected with the use of an applicator.

Self-locking

- Self-locking retaining rings connected on the bore that do not come with a grooved machine. Self-locking rings with no lug holes are difficult to remove without affecting the ring.

Design Considerations for Retaining Rings

- Retaining rings come in 3 types based on design. Tapered and constant section retaining rings complete a circle, having a gap between 2 ends.

- Tapered section rings have width reduction from the upper part of the ring to free ends. When connected, make a continuous connection with the installation grooves.

- Some tapered section rings are made to be used for axial installation, having lugs that help to easily expand.

- Constant section Rings have a similar width over the complete design. The stiffer cross-section makes a connection at 3 points in the installation groove. It is easy to make rings not have lugs.

- Spiral rings are made with flat wire that is coiled 2 or 3 times over the circumference. It makes a 360-degree connection in grooves and has constant width over the circumference.

- Spiral rings are made with installation lugs but do not have notched ends that are used for their removal.

Read also: What Is E-clip? Features, Working, Removing Process

Advantages of Retaining Rings

It comes with low shaft housing. With low weight and size for finished layout.

It has less cost for raw materials and labor costs.

It is lower cost than other fastening techniques.

It uses fewer raw materials for certain requirements.

It doesn’t need any certain training for assembly and is easy to connect.

It has a low manufacturing cost.

FAQs

What is a retaining ring also called?

- Retaining rings come with different names like circlips and snap rings.

What are the uses of retaining ring pliers?

- Retaining ring pliers are used for installation and removal of retaining rings. These pliers come with tips and are made for strong grip and manipulation of the retaining ring done at the time of installation or removal process.

What is the difference between a circlip and a retaining ring?

- Circlip and retaining ring are used as replacements, so they are known as the same type of fastener. They are ring-shaped and employed for making connections on shafts.

How to measure retaining rings?

- The retaining rings’ measurement is based on finding the size that is related shaft diameter where they are fitted. This measurement is used for providing accurate and strong fitting during installation.

What instruments install retaining rings?

- Some special tools used for the installation of retaining rings are normally retaining pliers. These pliers provide a strong grip on the ring and easy installation and removal.

Why is a retaining ring used?

- Its main use is to hold components on the shaft. The smooth, round finishing of the shaft makes it difficult for connect with other methods. Retaining rings clamp them and make shoulders that keep components in position.

What are the two main types of retaining rings?

- There are 2 main types of retaining rings: the first is internal retaining rings, and the other is external retaining rings. Internal retaining rings are put on the groove in the housing, and some internal retaining rings are tapered from the upper part of the ring to the free end of the ring.

Where do you put a retaining ring?

- Retaining rings are connected to the end of the shaft. That is normally handled installation and removal of radially connected retaining rings. Good is that not connecting the groove close to the end of the shaft avoids shearing.