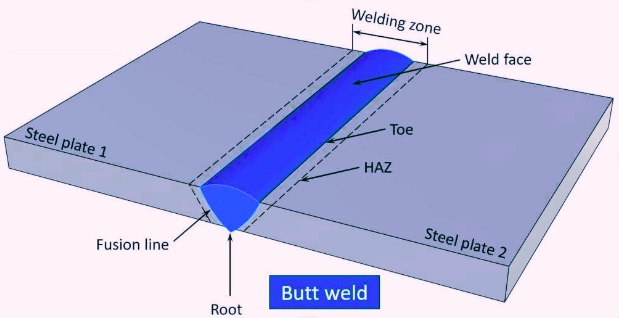

Butt welding is performed when two pieces of metal are configured end to end without overlapping and welded over joints. In butt joint surfaces, the working component is connected on the same plane, and weld metal lies in the flanges of the surfaces. In this tutorial we will cover details for butt welding features and other factors for performing it.

What is a butt weld?

- The butt weld is a simple type of welding joint. The joint is made by putting two working pieces of metal end to end, and after that, welding.

- In a butt joint, the surface of the working component is connected on the same plane, and the weld metals are in the surface plane.

- Working components are parallel and do not overlap, as compared to lap joints.

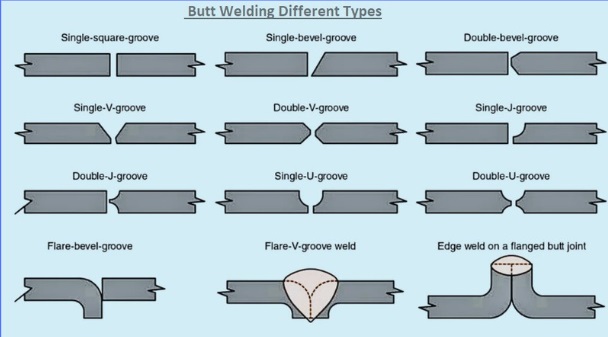

- According to metallic piece thickness, different grooves are made. Groove preparation is called weld edge preparation and is used for thick metals.

- Types of grooves are based on shape, like V-grooves, U-grooves, and J-grooves. Groove design variation based on penetration is either full or partial based on welding demand.

- Groove welding is performed with the use of different welding processes, like manual, mechanized, or automated.

- Thin sheet is welded without weld edge preparation. These joints are called square butt joints.

- Butt joints are welded with the use of arc welding, and high-energy beam and resistance welding used. It also performed a brazing operation.

- In the starting process, weld components help closely with tack welds that are temporary joints that make components in accurate alignment, and butt welding is performed there.

How Is Butt Welding Performed?

- Two pieces of low-grade metal connected in any direction, normally with a tabletop or wall fixture. In some conditions distance between metal is about 1/8 inch.

- Welder that added filler metal into the gap and applied an arc, resulting in a molten metal pool. Pool carried to joint length; more filler is added in a smooth stream.

- The distance between metals exists so molten metal can easily move through parts that are connected.

- If you have narrow space between metals, metal penetration is not accurately performed. If there is a very large gap, there is a high seam seen on the other side.

- Metallic thickness defines penetration degree; any top edges of metal products larger than 3/16 inches are chamfered.

- It can increase opening and provide good metallic flow over material thickness.

- If metallic pieces are high , there is no need to leave space.

Butt Welding Different Types

Square Butt Weld

- It is a simple square groove design. It is used for metal with dimensions of 3/16 inches in thickness and for conditions where joints cannot handle stress. Working components are fitted with each other based on joint type.

- Root opening is important based on metal and filler applied. The edges are not converted into round, beveled, or any other shapes. They round off, then weld, and the weld is put in the middle of the gap that exists between the butted stock parts.

- Congiuring base metal in a similar plan is important for proper square groove welding. Root opening welding needed a uniform gap in the weld.

Single & Double J Butt Weld

- The J groove is half a U groove. It used for the same applications as U-groove butt welds and faces the same difficulties for preparation and welding.

- It performed with advanced machines and the recommended direction for J-groove butt joint weld in a horizontal direction and 90-degree edges on the lower part.

Types of butt joints

- There are different types of butt welding joints, and their names are based on shape.

- Square groove wells come with different shapes for connection of metallic components, and these shapes handle bearing loads.

- The main types of joints are lap joints, tee joints, and corner joints.

- Lap joints are two components that are end over end and connected with each other, and butt welds are end-to-end connected.

- Butt welds are configured with each other through parent metal thickness.

- The other types of butt welds are single V, double V, square, single bevel, double bevel, double U, and single U.

- Reducing distortion in the weld is important, but it reduces complete penetration.

- For getting complete penetration, double welds like double V, double J, and double U are used.

Features of Butt Joints

Strength:

- If butt joints are accurately made, they have high strength due to complete penetration of the weld. So best for load-bearing structures.

Versatile:

- Butt joints are used for different materials and thickness ranges, so they are the best option for different types of projects.

Aesthetics:

- After properly finishing off butt joints, we can make a clean and good finish with the use of the GTAW process.

Efficiency:

- Butt joints use few materials and make a streamlined design that makes it a highly efficient weld.

Applications of Butt Weld Joint

Different applications of butt weld joints are as follows.

Piping Systems

- Butt weld joints are part of pipelines that are used for the transportation of liquids or gases since they make strong and leakproof connections.

Structural Manufacturing

- Different buildings and bridges of frames and machines, butt joints are important for making reliable structures.

Automotive Industry

- It is also part of the vehicle industry, which makes car frames to provide high-quality structure and control functions for different automotive components.

Sheet Metal Applications

- The projects that use sheet metals, but welding is used for connection of panels, make containers and other parts.

Aviation industry

- Different components of airplanes and spacecraft are made with the use of butt welding joints for making high-strength and reliable connections.

Advantages of Butt Welds

- Butt welds can easily be inspected and detected.

- It provides high strength for complete fusion of butt weld fillet materials.

- It is used for different metals.

- It can easily handle after welding; it is for processes such as grinding, polishing, painting, etc.

- It provides low distortion after welding, and pipe welding uses butt weld joints that are a low-cost option.

Disadvantages of Butt Welds

- It can affect due to varying surface conditions.

- Its applications are limited based on the geometry of welding.

- It can damage faces and crack them.

- It needed more cracking and fixing.

Butt Weld vs. Fillet Weld: Differences

- The basic difference between butt and fillet welds is the angle that connects working components. If surfaces that need to connect are on the same plane, it is made with a butt weld.

- If surfaces are at 90 degrees, they are connected with a fillet weld.

- Weld preparation is not used for fillet welds but is used for butt joints.

- In a fillet weld joint, filler metal is deposited at the joint in a triangular part so it makes an angle of 45 degrees with the joining working component.

- To get the required welding joint thickness, welding is performed with different pauses.

FAQs

What is flash (butt) welding?

- Flash (butt) welding is an electrical resistance welding process that is employed for component connection and with energy transfer through resistance heat of parts. Components are configured for end-to-end connection over a fully joint area.

What are the main features of welded joints?

- Through double welding, the depths of each weld are different. The closed weld is a joint type where two components for connection are touching at the time of the welding process. The open weld is a joint style in which two components come with a small gap at the time of the welding process.

What are the 4 types of welding joints?

- Butt joint.

- Lap joint.

- Edge joint.

- Tee joint.

- Corner joint.

What is resistance butt welding?

- Resistance butt welding is used for the connection of components having the same cross section by making a weld over the complete section in a single working. Heat is generated in the welding area through the resistance of current flow through parts held in a preset end force.

- When materials get heated, they force the soft materials to consolidate and finish the joint.