Die springs are used with die sets, with durable helical compression springs made of rectangular-shaped wire. This spring has features for handling high compression loads in different conditions and is normally used for punch presses to provide resistance based on requirements.

It is also used in various industries, where rectangular wire with rounded corners is utilized to make springs that function like standard compression springs. In this post, we will cover the details and features of the die spring and related factors.

What is a die spring?

- The die spring is a compression spring but has different features in that it is a high-force compression spring. It provides constant predefined pressure for certain compression. Die springs are also used for high-load conditions such as high-temperature conditions.

- Die springs are part of vehicles and heavy machine assemblies. It is also used for applications where high forces are applied in a limited space.

- It is considered that if the die spring has a strong design compared to compression springs, it will work well. But it is not true.

- Some assemblies were spring to be lightweight and make less conductive die springs heavy-duty designs.

- For compression springs and die springs, the material used, wire diameter, and different factors define the use of the spring and the conditions where it will be used.

- The accurate design Spring has features to handle high compression loads for harsh conditions and parts of applications where constant resistance is needed.

- Die springs have features to store more energy in limited areas as compared to round wire springs. But it does not have non-uniform pressure distribution over the rectangular area as compared to the round wire cross-section that has high energy capacity since more materials are used.

- Die springs are part of machine tools, but they are also used for high static loads for maximum life cycle.

- Rectangle wire used for minimizing solid height and providing high design efficiency

Materials of Die Springs

- Oil-tempered steel is a commonly used material for die springs. Chrome alloy is a common die spring material, having a chrome layer with wear and corrosion resistance.

- Chrome silicon or chrome vanadium is a low common but has a strong design that provides high accuracy for structures with reducing stress points and works in high-temperature conditions.

- This metal provides a pliable layer of colored vinyl on the spring that shows that the spring is in working load conditions.

Die Spring Specifications

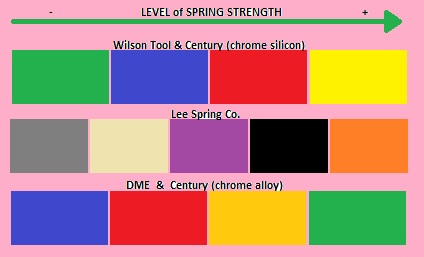

Color Coding

- The color-coding features of the die spring show their working load. There is not a proper standard provided by manufacturers, so check with the reference materials of certain manufacturers.

- Different shades denote a light range of heavy loads based on manufacturing details.

- Normally, there are four color-coded die springs used that have color coding of yellow, red, blue, and green.

- The yellow-colored die spring shows an extra-heavy load, which is a light load capacity. These springs are made for handling high loads and have reliable working based on applications.

- Red-colored die springs define heavy loads that have low load capacity as compared to yellow but have good strength.

- • The blue-colored die spring lies in the medium load range. They provide a balance of strength and flexible features for different industry uses.

- Green-colored die spring used to show low-load features where less force is used

Die Spring Wind Direction

- Direction of the die springs is clockwise or counterclockwise. When a load is applied laterally, there is no certain importance for winding direction.

Die Spring Ends

- It comes with two types of coils. The first one is closed, and the second one is open-ended.

Closed-end die spring

- With a minimized coil pitch of a closed end, wire lies on the remaining coils. As a result, the final coil of the spring is incomplete and reduces working features, causing a change in compression.

Open-end die spring

- Open-end die springs reduce pitch at the wire termination point, which results in an uneven surface in the case of the absence of ground. That is not an important point for die machines.

- Die springs in any type of end ground to make a flat and stable load-bearing surface.

Die Spring Dimensions

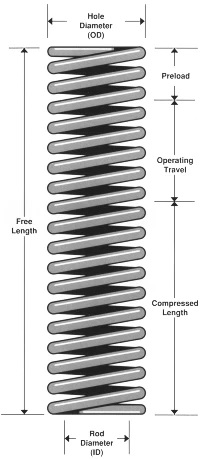

- Free length of the die spring is a dimension measured before load applications.

- Hole diameter used by the external diameter and the overall spring width. That width expanded at the time of compression.

- Rod diameter defines the internal diameter of the die spring made for fitting on the guide rod of machines.

- Wire diameter is the wire size used for making the coil.

Die Spring Applications

- The spring name is taken from their use in punch press die sets, where die sets apply pressure for holding material in locations and the press perforates the substrate.

- If the die set does not yield for the punch, the resulting punch can be affected. If it provides high yield, the material is not perforated.

- Die springs are used in transportation and agricultural industries.

Die Springs vs. Compression Springs

- Die springs can be the same as compression springs, but they are made for handling high environmental pressure, so they are also called high-force compression springs.

- They are reliable and have features for handling different strengths and are used for different applications.

- Die springs have closed or open ends, based on the product’s certain end use, and they also have color coding based on strength.

Features of Die Springs

- It has good working performance for high-pressure conditions and has high resistance to temperatures.

- It comes in different material designs, like steel and chromium alloys.

- It also has different sizes and designs with low-cost options.

- It can handle higher loads than other compression springs.

- It has resistance to wear and a flexible nature for heavy-duty environments.

- It can handle load in a reliable way with constant dimensions.

How to Select Die Springs

- Make sure that if spring is used for a short time, the average cycle is a long run.

- Use springs in the die based on space with low deflection.

- High-speed spring cycle, high work needed for proper working conditions.

- Check that hole and rod size is correct for the spring, since faulty spring details can cause damage for the spring.

- Load will be smoothly distributed for the replacement of the spring of the die at the same time.

- Not rework die spring with a grinding diameter. That affects spring and also tools.

FAQs

What are uses of die springs in an industrial setting?

- In industries, die springs are used for heavy load applications, for providing high force in press tools, molds, and die machines with low space uses. They provide constant working features for repetitive cycles.

Is it possible for die springs to handle heavy loads in manufacturing?

- The structure of die springs is such that they can handle heavy loads in the manufacturing process, so they are used for high-resistance applications.

Where are die springs most commonly utilized?

- The common uses of die springs are in vehicles, construction industries, agriculture, heavy machinery, and electronics.

What is the difference between die springs and standard compression springs?

- Die springs are made for high-stress applications and provide high strength and durability as compared to standard compression springs, providing a longer working life for heavy loads and higher cycling frequencies.

Define die spring in simple words.

- Die spring is a compression spring, but it is a type of high-force compression spring. It provides predefined pressure at a given compression. Die springs are also good to use for high loads in high temperatures.

What is the color code for die springs?

- Color : Range

- Blue : Light Duty

- Green : Extra Heavy Duty

- Red : Medium Duty

- Gold : Heavy Duty

Which factor do you consider for choosing die springs?

- First of all, get details for pressure, spring size and number for generating pressure, and how far the spring travels.

What is the working life of a spring?

- The industrial standard for the life of a spring is 10,000 to 15,000 uses, or it can work for 5 years on average. You can increase spring wire with different sizes and increase the working life of the spring by more than 100,000 cycles.

What are the types of die springs based on applications?

- Different die springs exist based on load demand, such as light, medium, heavy, and extra heavy loads.

What are the 4 types of springs?

- The main types of springs are compression springs, torsion springs, extension springs, and leaf springs.

- That is used for applications in industries.