The locknut is also called a lock nut, locking nut, or prevailing torque nut. It is a nut that comes to provide resistance for loosening in case of torque and vibrations. Torque nuts come with some part of the nut that deshapes elastically for the location process.

Free-spinning locknuts provide the feature of not using torque until seated. In this post we will cover features, details, and related factors.

What Are Lock Nuts?

- Lock nuts, also called locking nuts, are a type of mechanical fastener that provides resistance for vibration, shocks, and other parameters that cause nuts to become loose.

- Different processes are involved for providing resistance for nuts loosening through providing resistance and friction.

- Locknuts are screwed on bolts like standard nuts with strong fixing. Locknuts were first used in 1930; after that, it became easy to make strong connections.

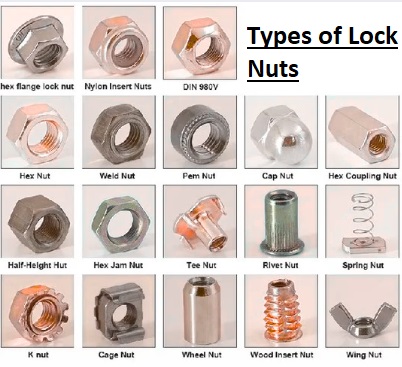

Types of lock nut

Locknuts come with two types of working features.

Friction between mating threads for controlling loosening

- Lock nuts that use friction are made with pitted grooves and use high torque for loosening and tightening. They do not spin easily over the fastener shaft since they clamp down when we rotate.

- So, longer time for assembly, and they are low-cost compared to other types of lock nuts.

- This category of nuts is called a prevailing torque nut since it provides resistance for rotation for assembly and removal.

Positive locking Features

- These nuts come with locks and are easy to rotate for tightening and loosening for assembly. It locks with positive action, some lock nuts need an insertion pin, and other comes with a small lip that the inner side crimps when connected for shaft gripping.

- It provides strong assembly and makes a strong connection. These lock nuts are high cost.

Types of Lock Nuts

Prevailing Lock Nuts

- Prevailing torque nuts operated with certain designs that provide resistance for turning of nut. That design comes with flanges for gripping threads in strong way. The prevailing torque means forced needed for tight grip. The common types of prevailing torques are as. Conical lock nuts,,Tri-lock nuts, Top lock.

Surface Bearing Lock Nuts

- The surface bearing locking nuts tightened from bearing surface for activating locking process that strongly grip at position. They are made with configuration of washer flange at one point. These flanges used for different uses such as Distribution of Load, the Locking Mechanism and Proper Alignment

Nylon Insert Lock Nuts

- Nylon insert lock nuts other name is nylon nuts, comes with nylon ring configured on upper part of thread. Nylon ring changes shapes for thread grip at time of tighten, provider resistance for vibration and strongly avoid nuts from loosening. This nuts comes with tight grip on threads of bolt.

Hex Jam Nuts

- Hex jam nuts comes with same thread size and pitch as compare to standard hex nut. it used as secondary nut for locking primary nut that reduces clearance between two fasteners.

Stover Locking Nuts

- These nuts are made with certain type of free spinning collar on upper part. If nuts tightened, collar bites in threads, provide resistance for rotation and minimizing automatic loosening features.

Center Locknuts

- Center locknuts, also known as crimping locknuts, come with central grooves that deform after tightening for a strong locking position.

Serrated Flange Lock Nuts

- Serrated flange nuts come with washer-like flanges having serrations on the inner side. These serrations grip the surface and resist vibration and provide strong self-locking.

Jet Nuts or K-Lock Nuts

- Jet nuts, also called K-lock nuts, come with a design that has different thin slots on the upper surface. These slots provide tension that avoids nuts loosening.

Castle-Lock Nuts

- Castle lock nuts, also called castellated nuts, come with notches cut on the surface, resembling the turrets of a castle. These slots are configured in conjunction with a cotter pin for securing the nut in the required position.

Tri-Lock Nuts

- Tri-lock nuts, also known as triple-lock nuts, come with 3 locking components on the upper surface. These components provide more resistance for avoiding loosening and are good to use for high-vibration applications.

All-Metal Lock Nuts

- They do not come with non-metallic parts such as nylon inserts. They based it on certain thread designs of thread for providing a locking process. These nuts are used in high-temperature conditions in place of nylon inserts.

Wedge Lock Nuts

- Wedge lock nuts come with a design that has one or more wedges. If a nut is tightened, these wedges, configured with threads, make a strong, mechanical lock that resists loosening. Wedge lock nuts are used for providing high resistance reliability for vibrations.

Locknut Features

The main features of locknuts are as

Thread direction

- Lock nuts come with clockwise and anticlockwise threading.

Locknut sizes

- It defines required sizes for locknuts in imperial or metric units.

Material

- Special types of components like washer locks accurately

Application of Lock Nuts

- Locknuts are used in the vehicle industry for securing different components such as wheels, axles, and engine components. They have features for handling constant vibrations and shocks related to vehicles.

- They are also used in the construction industry, like for securing scaffolding, reinforcing bars, and making connections of structures. They provide a strong connection that works longer.

- Lock nuts are also used in industries and manufacturing devices for components that handle high vibration, like for rotating machines.

- It is also part of the aviation industry for securing components in aircraft engines and landing gear.

- Locknuts are also part of marine applications such as propellers and engine mounts where moisture affects so strong locknuts are used.

Read also:What Is Sine Bar?- Features, Types, and Application

Lock Nut Sizes

Diameter (Size):

- It is the diameter of the threads on the bolt where the nut is used. The diameter is defined in metric units and imperial units. Such as a metric lock nut comes with a nominal diameter of M10, and an imperial nut has dimensions 3/8-inch diameter.

Thread Pitch

- Thread pitch defines the distance between neighboring threads on a bolt. It also explains in metric units. Such as M12 x 1.2 lock nuts, it shows that it is made with a 12mm diameter bolt and the thread pitch is 1.2mm.

Why are lock nuts used?

- It is used for controlling loosening at the time of vibrations and securing bolts in different applications.

- It has tightening and loosening features and a grip with a knurled pattern.

- It also provides stable features through serrated flange design.

- It also has double tightening through 2-way lock nuts.

- It reduces the use of extra washers through K-lock nuts.

- It provides a locking system through flex lock nuts and makes for strong fastening with a combination of nut and locking washer.

Lock Nut vs. Lock Washer

Lock Washer

- Its main use is to prevent nuts or bolts from loosening due to high torque or vibrations.

- The common types are internal tooth lock washer, external tooth lock washer, and split washer.

- It is configured between the nut head and the surface to provide friction through serration in case of compression.

- It is not seen when connected and uses more steps for installation.

- Fastening used for nuts and bolts

Lock Nut

- It is used for avoiding nut loosening due to torque or vibrations.

- Its common types are prevailing torque lock nut, nylon insert lock nut, flange lock nut, etc.

- It is used as a replacement for a standard nut, connected directly to the bolt.

- It follows different systems, such nylon inserts, flanges, and serration, to provide resistance against loosening prevailing torque used.

- It is used again and again without the effect of the locking feature.

- It has different types and finishes and is connected like a regular nut.

Lock Nut vs. Hex Nut

- The lock nut’s other name is locking nut, which is a nut type that is used for securing a bolt in position.

- • A hex nut is a nut that comes with a a hexagonal design.

- Lock nuts made with steel and hex nuts are made with brass or bronze.

- Locknuts are more expensive than hex nuts.

- Lock nuts are in a strong position as compared to hex nuts in case of friction.

- Hex nuts are stripped as compared to lock nuts.

Regular Nut vs. Lock Nut

Lock Nut

- Lock nuts become less loose as compared to regular nuts since the groove or thread on the inner side provides a strong grip and stops motion.

- Lock nuts come in different types of materials based on applications.

- But lock nuts are difficult to remove when they tighten. Since the groove on the inner side grips the bolt strongly. Lock nuts are reusable when removed.

Regular Nut

- Regular nuts are less costly than lock nuts, and they come in different materials based on uses.

- Regular nuts are less effective for bolts to become loose. Since no groove exits inner side for the grip bolt screw. Regulars also reused

FAQs

Why is a locknut used?

- Locking nuts are a certain type of fastener made for providing strong fixing. These are also called self-locking nuts. They screwed on bolts like standard nuts, and lock nuts come with features for resistance to loosening in case of torque or vibration forces.

What is the difference between a nut and a locknut?

- Lock nut made to provide resistance to loosening than a standard hex nut. Lock nuts are used for handling vibration or force effects that make nuts loosen with time.

Are a lock nut and a stop nut the same?

- Nylon lock nuts or stops are a low-cost option and come with a nylon insert that is smaller than the thread diameter.

- Nylon insert lock nut tightened, collar deshaped through mating diameter, and friction provided.

What happens if I lose Locknut?

- Locking nuts have a certain code, so the manufacturer can order a new number of that type.