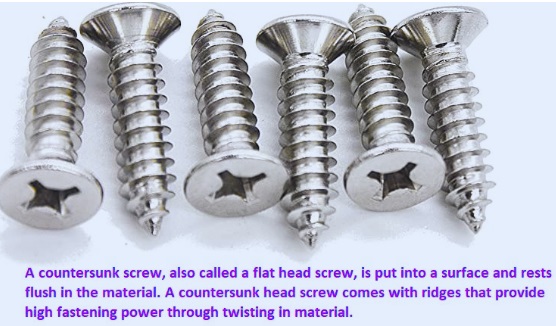

A countersunk screw, also called a flat head screw, is put into a surface and rests flush in the material. A countersunk head screw comes with ridges that provide high fastening power through twisting in material. A countersunk screw comes with a flat head.

In this post we will cover details for countersunk screws and their related features.

What are countersunk screws?

- The other name of a countersunk screw is a flat head screw that is used to rest flush on the surface where used.

- They can easily sink into different surfaces. It comes with a flat head that tapers over the shaft. When we use a countersunk screw on a surface, its heat passes through the surface material.

- These screws, as compared to other screws, come with a flat head and also have helical ridges.

- Countersunk screw flat head features help them to be put into different surface materials.

Non-Countersunk Screw Head

- The non-countersunk screw head protruded out of the surface where it was used. It does not sink into the surface but protrudes out.

- • A non-countersunk screw head does not taper towards the shank. It comes with a narrow shank that comes with a wide head.

- They can connect on their head without tapering. When the head strikes the working area, the screw does not work. so a non-countersunk screw passes through surfaces.

- These screws are used in woodworking and mostly preferred over countersunk screws since they apply low pressure on working components.

- • The tapered area over the countersunk screw is larger than the shank.

- So the connection of countersunk screws can damage the working piece. while non-countersunk screws do not have tapering that avoids such damage.

- In non-countersunk screws, only the shank passes into the working component.

Types of countersunk screws

Thread types

- There are different types of countersunk head screws, and they come in two basic types based on tail. The first one is a countersunk head point tail screw and comes with pointed self-tapping threads. such as wood screws, self-tapping screws, and drywall screws, are pointed countersunk head screws.

- Another type is the countersunk head flat tail screw, also called a machine screw, made with fine threads.

Driver Type

- For countersunk head screws, different driving techniques are used, like Philips slotted, Torx slotted, pentagonal slotted, and triangular slotted.

- These types of screws are made into self-tapping threads.

Types Of Countersink Bits

- Different methods are used for countersunk screws. The main technique is to use bits made for certain uses, and there are types.

Predrill Countersink Bit

- The pre-drill countersink bit helps to make a pilot hole for a screw with a combination of countersink holes. This process provides constant work when we move from screw to screw.

Stand-Alone Countersink Bit

- The other process is to use 2 different drill bits. The first one predrills holes for screws. The other bit makes cone-shaped holes in the surface of the wood that help the head of the screw to sit below the surface.

- It is a time-consuming process, but it provides clean holes. The stand-alone countersink bit used for wood as well as metal provides good work if used for both.

Countersunk Screw Head Features

Countersunk screw heads come with different features and are used for certain applications.

Flat Head:

- The common type of countersunk screw is a flat head that comes with a conical shape that sits flush with the surface in case of accurate connection.

Oval Head:

- It is like a flat head but has a slightly rounded upper part. These features provide a close-to-flush surface.

Bugle Head:

- It is used for drywall connection; the bugle head comes with a trumpet shape that helps to easily sink the tip into drywall without the paper facing tearing.

Countersink Without a Bit

Use these methods for making standard bits if you do not have a countersink bit.

Two-Drill Bit Process

- Predrill a hole that is according to the diameter of the screw used. Put a piece of tape on the bit for marking the stopping point at the same length as the screw to avoid going through the material.

- In the next step, use a bit that is a larger size than the screw head. Create a shallow hole for the head of the screw to sit below the surface of the material.

- It makes a clean hole but also makes for wood filler covering.

Philips Head Bit Method

- If you do not have a countersink bit during your work, they use a Philip head bit and put in a point where the screw is used. Starting the drill and moving over the circulation direction increases the hole according to the required size.

- This process cleans the hole in case of a small size. The screw head lies over the wood surface, and the wood filler does not hide it.

What is a countersunk screw used for?

There are different applications where countersunk screws are used that are explained here.

- It is used in woodworking; the furniture industry uses it for beds, tables, benches, and sofas that are made with different scenes. countersunk head configured in wood and no protruding component that affects design.

- It is also used for the construction industry, such as doors, windows, and railings, and used for fixing different places with countersunk head screws.

- It is also part of the electronic industry for fixing the shell and inner part of appliances like refrigerators and conditioners.

- It is also used in different machines like CNC lathes for the connection of different parts.

- For vehicles, countersunk head screws are used for engine parts and other components.

- They are also part of the aviation industry, where titanium alloy or stainless steel screws are used to avoid corrosion.

Advantages of countersinking screws

- Countersunk head screws come in different shapes that help to use them for different applications.

- It is low cost, easy to connect, provides a good fastening effect, needs low maintenance, and has a wide range of adaptability.

Installation and disassembly of countersunk screws

- Before connection, mark the accurate position of the screw and hole created with the use of a drill based on the head angle.

- • The hole needed to be larger as compared to the conical head of the screw. When the reaming process is complete, use a screwdriver based on the groove type to tighten it.

- For the disassembly process, unscrew in the reverse direction with a screwdriver. Rusty screws soaked in lubrication materials are then used for unscrewing purposes.

- For removing a screw that is difficult to remove, a certain type of tool can be used.

Countersunk screw dimensions &angle

- normally used size for counters head screw in from m2 to m30 M2, M3, M4, M5, M6, M8, M10, M12, M14, M16, M20, M22, M24, etc.

- length in rang of 10mm to 100mm. you can also use your customize size

angle of a countersunk screw?

- normally used screw countersunk angle is 90 degrees to 110, 120 degrees and countersunk head screw angle in range of 100 to 130 digress.

FAQs

How do you countersink a screw?

Follow these steps.

- Use an accurate bit; select a countersink bit that is according to the diameter of the screw.

- With use of a marker, define the mark where the screw is needed to be inserted.

- drill pilot hole,

- countersink hole and drive screw

- in last Sand and Finish.

What is the difference between countersink and countersunk?

- Countersunk holes are used in metals and wood screws, and counterbores are part of larger fasteners, such as lag bolts.

- Normally countersinking uses small pilots as compared to counterboring, so countersinking is used for heavy loads in construction machines.

What is the purpose of a countersunk screw?

- The use of countersunk screws has different features. It provides an easy drive screw and makes a good design hold. It provides safety and quality for woodworking.

What is the process of countersinking?

- Countersinking is a machining process that is used for making conical holes at the upper part of predrilled holes.

- This conical hole is made for providing the head of the flat to sit flush below the surface of the materials.

What is the normal angle of a countersink?

- The angle for countersinking is based on hardware used. Normally hardware comes with a 50 percent connection with a countersunk hole. The standard countersink angle for hardware is 90 degrees, and the standard countersink angle for imperial hardware is 82°.

What is another name for a countersunk screw?

- the countersunk, also called flat head, screw that sinks into the surface and rests flush in the material

What are countersunk vs. flat head screws?

- The countersunk screw head is also called a flat head and comes with a level head. The main motive of a countersunk screw is to provide a screw to level the surface where it is screwed. The bugle screw is like a countersunk screw that has a flat head.

What is the difference between a countersunk and a bugle head screw?

- • The difference is that bugle head comes with a rimmed concave on the inner side of the flat head, and that curved inner edge makes bugle head good to use for different materials such as wood and drywall.