The drive shaft, also known as a propeller shaft, is a crucial component of vehicles and other machines. It is important to transmit power from the engine to the wheels that provide motion of the wheels. The propeller shaft is also important to transform engine power into kinetic energy and causes the propeller to rotate with the required speed, and as a result of the propeller rotation at the given speed, the vehicle moves.

The propeller shaft is a mechanical part of different vehicles and industries used to transmit torque and power at different parts. In this post, we will cover the detailed features of the propeller shaft, which is also called the drive shaft, and related working.

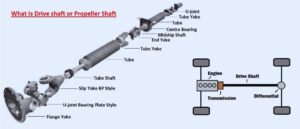

What Is a Drive Shaft or Propeller Shaft?

- The drive shaft, also called the driving shaft, propeller shaft, or cardan shaft. That is a component used for the transmission of mechanical power, torque, and rotation that is used for making connections of different parts of the drivetrain. That does not make a direct connection due to the larger distance.

- It carries torque, so it faces torsion and shear stress that is equivalent to the difference between the input torque and load.

- So it has a strong structure for facing stress and avoiding extra weight since it can change in shape due to inertia.

- For changes in alignment and distance between driving and driven parts, drive shafts come with one or more universal joints, or rag joints, that is, splined joints.

- In conventional vehicle design, where the rear-end engine is, this shaft helps to provide propulsion of the rear wheels. that transmit power from one point of the vehicle to the other.

- in advanced vehicles short shaft is used, while the propeller shaft is an important connection of the chain of power transmission in vehicles and marine

Features of Propeller Shaft

- The propeller shaft with different features, like the main function, is to transfer power from the gearbox output shaft to the differential.

- It provided high efficiency with reducing power losses at the time of transmission which helps to get a constant rpm level.

- It is also used for transmission power over different elevations, like it can easily send power from the gearbox output shaft at a higher distance to the ground.

- • The propeller shaft also has features for controlling vehicle navigation of obstacles like speed breakers.

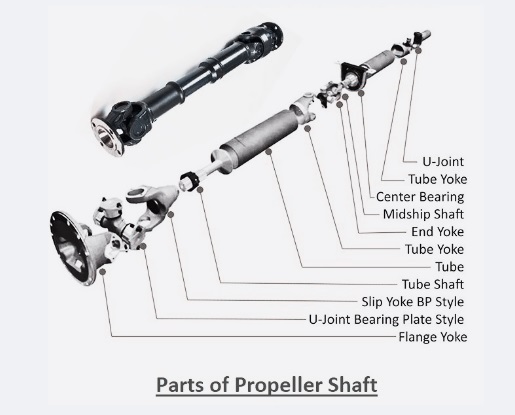

Parts of Propeller Shaft

Different parts of propeller shafts are explained here.

Universal Joint

- The universal joint is an important part of the propeller shaft assembly, which comes with two joints in one unit of shaft. but it can be different numbers, about 3 or 4 joints, based on the shaft.

- The universal joints provide rotational motion of the propeller shaft over different axes, and they also compensate for the elevation difference of the gearbox output shaft and the differential.

Slip Spline Joint:

- This part lies at the output side of the shaft, and it is important for torque transmission according to shaft length.

- It works at times when driving on rough roads where different obstacles exist. like rear wheels compress the propeller shaft when the vehicle moves over a speed breaker.

- When pressing the obstacle, dampers push the rear wheels and convert the shaft to real length. During moving, an obstacle slip spline joint transmits power and saves the shaft from compression and tensile stress.

Tubular Shaft

- tabular shaft used for managing distance between gearbox and rear axle. the number of tubular shafts based on the propeller shaft. It is a longer or shorter shaft, based on the distance between the gearbox and axle.

Flange Yoke

- This part is used for making a connection for the complete drive shaft assembly with the gearbox, which provides a strong connection.

Bearings:

- Bearings are put at different rotational joints over the shaft. Its main working is to minimize friction heat production and increase efficiency and propeller shaft design.

End yoke:

- This part of the propeller shaft is an important component that makes a connection with the shaft and drivetrain parts. It comes in a fork-like design, having arms that cover the shaft and make a connection with other flanges or parts for rotational motion and torque transmission.

Midship Shaft:

- It is a propeller shaft system that lies at the middle of the shaft length to provide compatibility and accurate alignment. It helps manage bending and torsional stress that exists for longer propeller shafts and provides smooth power transmission from engine to propeller.

Slip Yoke and Tube Yoke:

- It is the main part of the propeller shaft structure that is made for managing variation in the length of the shaft as a result of suspension motion. The slip yoke has a splined sleeve that moves over the shaft and makes a connection with the transmission, allowing the shaft to expand or contract when the suspension moves. The tube yoke lies at the backside of the driveshaft.

Difference Between a Drive Shaft and a Propeller Shaft

- The drive shaft and propeller shaft are used for the transmission of power, but their working is different based on the vehicle and the connection position.

- The drive shaft is a cylindrical component that transmits the rotation of the rear axle differential in the rear-wheel-drive gearbox in rear-drive or front-drive vehicles.

- Its main function is to send rotary motion from the engine to the wheels.

- • The drive shaft comes with high torque and is connected with universal joints that provide vertical or horizontal motion.

- propeller shaft comes with different features A longer type of shaft is used in trucks, buses, and rear-wheel cars.

- It lies between the gearbox and final drive unit.

- propeller shaft also used for marine and airplane for transmission of engine rotational power to propellers.

- A driveshaft is used in small vehicles.

Driveshaft Working

- The driveshaft is a spinning tube that delivered power from the engine to the rear of the vehicle at the differential. For this, it transmits spinning power from the front side to the back.

- It delivers torque from the transmission to the differential that sends torque to the wheels that move the vehicle.

- If there is no torque transfer between distinct parts, driving is not possible. The driveshaft absorbs motion and helps to move different parts without breaking drivetrain parts.

- The good thing is that front-wheel-drive vehicles do not have drive shafts. The transmission and axle lie in an assembly that is the transaxle.

- 4-wheel and rear-wheel drive vehicles come with different transmission and axle units. So the driveshaft sends turning movement to the axle in the form of transmission.

Types of Propeller Shafts

Single-piece propeller shaft:

- This type comes with 2 universal joints, one slip joint, and the other is a tubular shaft. It is used for providing short-distance transmission. It is used in cars and also used for front-end 4-wheel drive.

- It has good strength for design and is more anddurable as compared to a 2-piece propeller shaft since it has friction welding at junctions.

Two-piece type propeller shaft:

- 3 universal joints exist, coming with one joint and 2 tubular shafts in a two-piece design. It is used for longer distance transmissions, like buses and trucks.

- The larger number of joints causes low strength. It is low in durability due to the absence of friction welding. It also transmits lower torque than a single piece.

Types of Drivetrains

Rear-wheel drive (RWD)

- The rear-wheel drive system comes with a drive shaft for power transmission from the engine at the vehicle’s front to the back side. This feature is used usedfor cars, trucks, and larger sedans.

- RWD vehicles come with good weight distribution features and accurate handling for acceleration.

Four-wheel drive (4WD) and all-wheel drive (AWD)

- 4WD and AWD systems come with different drive shafts for power delivery to 4 wheels. It also has good traction and stability for different driving conditions. 4WD is used in off-road vehicles and trucks, and AWD is commonlyused for cars and crossovers.

Front-wheel drive (FWD)

- This system does not come with a conventional long drive shaft. but uses a shorter driveshaft, which is an axle shaft for the transmission of power from the transaxle to the front side wheels.

- This design is used for passenger cars since it has a compact design and high fuel efficiency.

Advantages of Propeller Shafts

- Propeller shafts provide good power transmission, which causes low power loss at the time of working and increases efficiency.

- It is low weight due to the tubular design and affects vehicle net weight and fuel use.

- The design of the propeller shaft is simple and easy to make with low cost.

- This module provides safe and secure power transmission from the engine to the wheels and provides power during driving.

- It is made with high-quality materials and provides good working in different conditions.

- its sturdy design and effective power flow The propeller shaft uses low maintenance and reduces costs.

Limitations of Propeller Shafts

- The propeller shaft gets damaged if it faces high rpm, which results in damage.

- Manufacturing of hollow propeller shafts is high cost and increases cost.

- It has low strength and changesshape when facing high pressure.

- • The propeller shaft is not good for handling high bending that causes design problems over time.