Metal forming is a manufacturing process that makes structural components and parts from metal sheets or tubing. The process involved metal forming, bending, or reshaping a metallic component into the required design and shapes. Metal forming is not only used for industrial processes but also important for different methods.

In this process, a larger number of materials are used. The manufacturing process can make parts in different applications, such as industrial sectors, vehicles, agriculture, and commercial electronics.

What is metal forming?

- Metal forming defines the process used for reshaping metallic components into different shapes with the use of force and different types of deformation processes.

- It uses metallic materials manipulation that are sheets and rods in different shapes and structure.

- This process is performed through different steps and methods; each uses different tools and devices. In some way, it converts raw materials into different working parts.

- Basically, metal forming is the bending, stretching, and compressing of metal.

- It is good to use for different product creations, such as utensils and car components, and also complicated machines.

How Metal Forming Processes Are Performed

Metal forming applies stress or pressure on metal for plastic deformation and changes the geometry of materials in different parts that are used for industries.

Whichever type of forming process you are using, each faces material tension, compression, and in some cases, both.

In this process, metal does not face any mass into mass, just a change in structure.

There are different types of metal forming processes used for bulk production in the manufacturing industry. The commonly used types are as

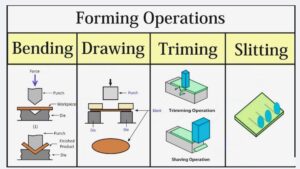

Bending

- Bending is a metallic forming process; bending uses a brake press or other press machine. The metal sheet is made by putting it over a die block that punch-presses the materials. The die not only punches a hole in the metallic sheet but also applies a bending force that converts the metal into a die.

Stretching

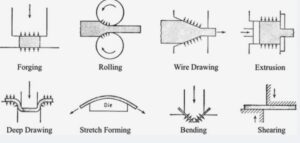

- It is also a type of metallic processing. The forming process comes with stretching and bending working components at the same time on a die to make complicated parts and larger components. The deformation of the sheet occurs through radial strain. This process is used for shaping larger components into the required size at accurate bends through providing smooth surfaces.

Deep drawing

- It is a common type of metal forming process. This is the process where a metal sheet is clamped in a certain position on a cavity-shaped die that makes hollow design components. The movement of the punch applies downward into the cavity. The tensile strength applied on the metallic sheet to reshape the different designs of the component

Roll forming

- It is a process that changes the metallic shape through the application of a set of rollers. When metal is passed through a machine, roller pairs make and bend sheets in different shapes with certain cross sections.

- This process is applied slowly, making parts in the required shape. Roll forming makes components that have longer lengths and bulk production.

Types of Metal Forming Processes

Bulk Forming Processes

- The bulk forming process uses raw materials that have a low surface area with a volume ratio for shape conversion. This type comes with different process uses such as rolling, forging, extrusion, and drawing.

- For bulk deformation there are different forces like compressive, shear, and tensile, and in some conditions these forces are all applied.

- Forming presses come with tools and die sets for bulk forming, used to make different parts like gears, bushings, and different parts of engines.

Rolling

- For the metal forming process, rolling is used that minimizes thickness and changes the cross-sectional design of metallic components. Where materials pass through rotating rolls and compressive force is applied

Extrusion

- Extrusion is a process used for making different particles with fixed cross-sectional features by forcing material into a die. The material in the shape of a billet is passed through a die with the use of a ram or screw mechanism.

Forging

- Forging is a metalworking process that uses compressive forces to reshape a metal component into the required design. The process uses high temperature to provide plasticity, but some materials need a low-temperature forging process.

Sheet Metal Processes

- Sheet metal forming uses tensile forces and works with sheets, plates, and strips. Sheet metal operations involved bending, drawing, shearing, punching, and blanking, which are performed with the use of pneumatic presses. Die and punch sets are used for this process.

Bending

- Bending is commonly to use for sheet metal forming, where a brake press is used for reshaping metallic sheets.

Curling

- Curling is used for refining the sharp and rough edges of metallic sheets.

Ironing

- Ironing is used for providing constant thickness and uses the ironing process for aluminum cars

Laser Cutting

- Laser cutting is becoming a common process for sheet metal forming. This process is performed through sheet metal facing a high-strength laser that provides metallic perforations.

Hydroforming

- It is a less common method for sheet metal forming; it is like a drawing process that involves elongating a blank on a die.

Powder Metal Forming

Power metal forming is an advanced type of process that has different features. This method helps components to make components close to the required shape and reduces material waste.

Powder helps to make adjustments for material composition for getting required features. Sintered metals with powder shape provide good formability as compared to wrought materials.

The difficulty exists for reducing porosity since it affects strength, ductility, and corrosion resistance and provides component damage.

The metal forming process is also defined according to the deformation force applied on materials at the time of forming. That are

Casting

- Casting is a metalworking process in which molten materials like metal or plastic are applied to a mold and, after some time, become cool and solid. This process is used for making complicated parts and components and is important for different industries like vehicle and aviation.

Stamping

- Stamping is a process that uses pressing sheet metal and other materials through the use of a die and press. This process makes different parts, from small-level to complicated parts, in different industries like electronics, vehicles, and manufacturing with high accuracy.

Different Metal Forming Materials

Different metals and alloys are used for the metal forming process based on applications and requirements. Some are as.

Steel:

- Steel provides high strength and low cost material and is commonly used for different designs in vehicle parts and in the manufacturing industry, which is also part of the construction industry.

Aluminum:

- It is low weight and part of the aviation, vehicle, and construction industries since it has low corrosion resistance and good shape-change features.

Copper:

- It has good electrical malleability and conductivity features and is part of wiring, plumbing, and other uses.

Brass:

- Copper and zinc combination makes brass that is used for decorative purposes, fittings, valves, and devices since it has a good look and provides corrosion resistance.

Titanium:

- It has a good strength-to-weight ratio and high resistance to corrosion. Titanium is used in medical devices and high-performance machines.

Nickel:

- It is used in alloys since it has high resistance to heat and corrosion and is good for the chemical, aviation, and electronic industries.

Magnesium:

- It is a low-weight material and used for aviation industry vehicles and electronic components since it provides low-weight features.

Custom Alloys

- Alloys with different metals like brass, bronze, and steel alloys used for providing strength, corrosion resistance, and conductivity for different uses

Tools of Metal Forming:

Dies and Molds:

- It is custom-made and used for shaping and cutting metals in different shapes. Die is used for stamping, punching, and extrusion processes.

Presses:

- Hydraulic, mechanical, and pneumatic presses, such as press brakes, provide force for making different shapes of metal. It comes in different sizes and capacities and is used for different functions like ironing and drawing.

Rollers:

- It is good for roll forming, and this tool helps to bend and change the shape of metals in long and different cross-section values.

Cutting Machines:

- Laser cutters and shears are used for cutting metal sheets. Laser cutting provides high accuracy with low waste.

Welding Tools:

- There are different types of welding processes and tools, such as ARC welders, MIG, and TIG, used for the connection of metallic parts with high strength.

Advantages of Metal Forming

- This process does not involve the removal of materials and has low scrap as a result of providing good material uses.

- It provides high strength and hardness for materials made. Forging provides an accurate flow of grain and process for material cellular design; as a result, we get a reliable structure and good toughness and fatigue strength.

- The forming process comes with a notable stamping and rolling process that comes with different automated processes that provide high production with low cost.

- Different forming processes make components that need very little machining; as a result, extra time and cost are reduced.

- The cold forming process also provides accurate surface finishes.

- It also reduces cost for bulk production since it has low production cost for bulk production.

Limitations of Metal Forming

- Tools used for molds and dies are high cost for metal forming that is low cost for low productions.

- It makes simple designs but faces difficulty making complicated structures and designs.

- In case of bending when forming forced losses, strength, and removed parts, try to get the original shape through elasticity that needed extra bending.

- Plastic deformation provides directional features for materials that do not require some applications.

- The final assembled product can have residual stress that needs extra post-process treatment for relieving

Safety Factors for Metal Forming

There are different safety factors needed for performing the metal forming process that make this process safe and reliable for users. Some factors are as

Skill

- Make sure that working people are well trained and know about the machining process and follow safety parameters.

Personal Protective Equipment (PPE):

- The workers also use proper safety measures like glasses, ear protection, and gloves.

Tools Inspection:

- Regularly inspect the press, rollers, and other machines for any fault and other hazards.

Emergency Procedures:

- Set emergency protocols and provide that all workers and staff know these processes

Safe Working Environment:

- Must have a clean and properly managed system for working well at that place for providing safe working and protection for machines

Conclusion

Metal forming is an important factor and process used in the manufacturing industry. It provides advanced automated processes for increasing productivityin industry.