Abrasive flow machining is also called extrude honing. It is an inner surface finishing process that uses abrasive-laden fluid that is applied through a chamber that gets the cleaning process. Fluid has a viscous nature that provides a smooth finish for inner surfaces that are difficult to approach. This process is applied on rough surfaces, removes errors, and also helps to make a larger size of chamber. In this post we will cover details for the abrasive flow machining process and related factors.

What is abrasive flow machining?

- Abrasive flow machining (AFM), also calleed abrasive flow deburring and also known as extrude honing. It is an inner surface finishing process where abrasive-laden fluid flows in the working component.

- Fluid has a viscous nature with dough-like features. This process makes rough surfaces smooth and helps to remove burrs, polishes surfaces, and also removes materials.

- This process is best to use for inner surfaces, holes, and slots and helps to approach parts of material that are difficult to access.

- It is not preferred for larger stock removal functions since it has a low material removal rate. It has had importance in different processes since 1970.

Abrasive Flow Machining Working

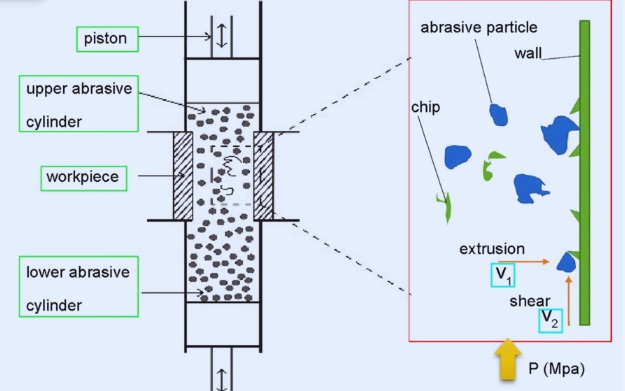

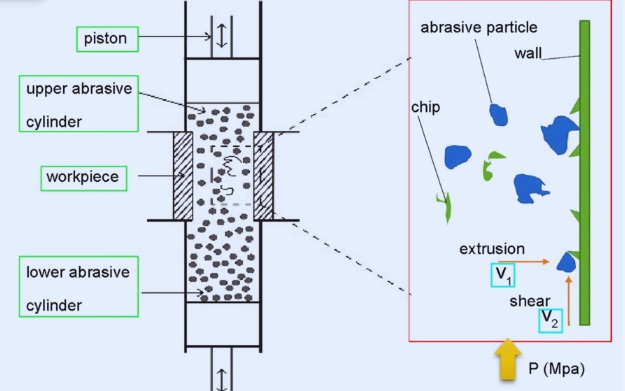

- Abrasive-filled fluid passes through materials at the time of the extrusion honing process. Elevation of the surface is removed when making a connection with an abrasive fluid, like sandpaper removing wood splinters.

- Hydraulics move fluid at the time of the process, and viscous material is converted into a mold of the accurate shape of the materials.

- Abrasive flow machining works in a two- or one-way flow process.

- The working piece is created through back-and-forth motion of a semisolid abrasive medium. The process is abrasive in the extrusion area, and it has constrained flow.

- Abrasive media hone the surface gently and simulate the lapping process.

- This process helps to make accurate shapes of materials like soft aluminum, nickel alloy with hard design, carbides, and ceramics.

Abrasive Flow Machining Equipment

- • The abrasive flow machine comes with two medium chambers, hydraulic rams, a fixture that holds the working component, and a clamping system that manages all components.

- Some machines are used for loading different abrasive media and also have features for setting the pressure applied for extruding the medium through the working component.

- They can work manually or using an automated CNC machine. A machine that is made for handling high production and devices for cleaning of parts, unloading and reloading stations, and media heat exchangers also exists.

Abrasive Flow Machining types

One-Way AFM

- One-way AFM performs a unidirectional function and moves the abrasive medium in one direction over the working component. It is easy to configure as compared to multi-directional machines.

- Abrasive medium extruded on a single cylinder medium on the working component and after that on the receiving chamber.

- Media flows in in one direction, and abrasive grains affect the surface in a certain direction.

- It is an easy and low-cost process but not effective for providing smooth finishing for complicated designs.

- It is used for light polishing of basic inner surfaces.

Two-Way AFM

- Two-way AFM is a commonly used machine, and it provides oscillating features. It provides good finishing for complicated designs.

- In this process media move back and forth in two directions through working components with double-pressure medium cylinders.

- The dual operation of this abrasive medium machine flow helps abrasive grains to work for cutting surfaces at different angles, resulting in smooth material removal and a good surface finish.

- It provides a good surface finish and material removal due to dual direction.

- It is good to use for complicated designs and intersecting holes.

- It provides good polishing and radiusing with that used for polishing of turbine blades and also part of the aviation industry.

- It also performed the finishing of medical implants and surgical tools.

Orbital AFM

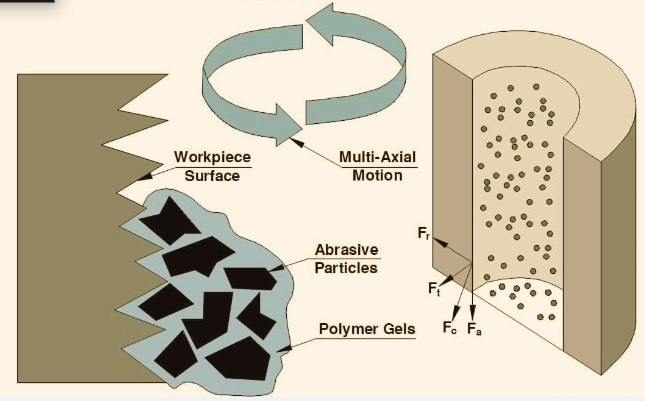

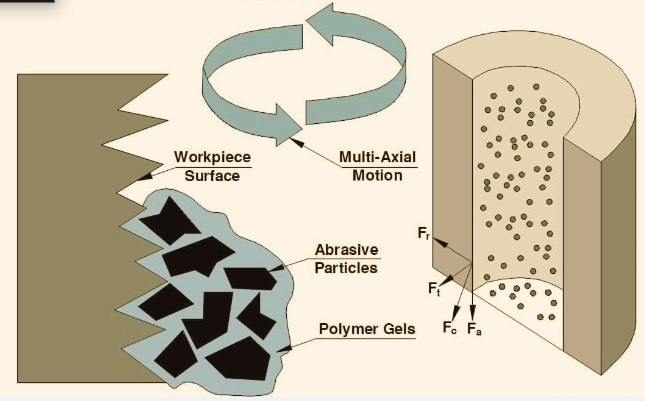

- Orbital AFM performs motion through the motion of working components and tools. It provides an extra abrasive process and also good control for the process.

- abrasive medium traversed over the working component and extra orbital motion that is provided to the working component.

- This movement provides nonlinear features for the track where abrasive medium moves over the surface which provides repetition and work for certain locations.

- It provides control for the surface finishing process and increases smoothness for surface finishing for handling complicated parts.

- Orbital AFM is good to use for finishing components where a nonuniform layout exists.

- It has limitations that needed complex instruments and also needed special fixtures.

- It is also part of mold polishing and dies where complicated patterns exist.

Multiple-Passage AFM

- This method is used for larger working components that need to be processed with different patches for abrasive mediums in sequence or parallel combinations.

- It comes with a design of tools that helps the abrasive medium to move on different paths or different materials at the same time.

- Tooling helps to process the same components at the same time and also handle different parts of larger components in series.

- It is used for bulk volume manufacturing and provides high efficiency and different components.

- It also manages larger designs. Tooling design is complicated and high cost.

Extrusion Honing

- Extrusion honing is a special type of AFM that works on bore finishing and bore sizing. It is used for inner cylindrical surfaces. In this process high-viscous and abrasive polymer medium moves through the bore in high-pressure conditions.

- medium overcontrolled flow Make flexible honing tools that provide good surface finishing through removing materials and have an accurate inner dimension diameter.

- Extrusion honing is performed in 2-way tooling features.

- It provides good bore roundness with proper internal diameter, having a good surface finish.

- It removes micro burrs and is a low-cost option for honing small and larger diameter bores.

- It is used for performing accurate cylindrical internal designs and needed special tools for holding working components and medium.

- It is used for finishing hydraulic valve bodies and sleeves.

Abrasive Flow Machining Features

- The AFM process easily polishes inner passages and complicated designs that are not easy to access with normal tools.

- The thickness of deburring is self-deforming and provides a uniform connection with the working component surface and also easy removal of different materials. It also provides a smooth finish on different angles and designs.

- AFM provides the same controlled radius for edges that are important for managing stress and also increases the working life of components.

- It removes burrs that exist after the machining process and removes any premature components and overall affects working life. Minimizing stress also increases durbality of the component.

- AFM did not generate any heat, so no thermal distortion exists and it did not affect the material’s features.

- It operated on different alloy metals such as steel, aluminum, and ceramic materials, and also on plastics.

- It provides a good surface finish; deburring provides good flow and low ear and also good performance.

- AFM is also performed in an automated way for high volume and provides high efficiency for production and reduces working costs.

Limitations of Abrasive Flow Machining

- AFM machines are costly processes, and abrasive mediums are also used for limited times since they have consumable features.

- It is a finishing process with a low rate of material removal, especially compared to other machining processes, and it is not good to use for larger material removal processes.

- It takes some time and also needs high optimization, like a viscous medium or a type of abrasive with proper dimensions.

- It needed to use special types of tools for accurate abrasive medium flow through complicated passes that could not be performed without expert engineers.

- AFM is good to use for inner finishing passages but not effective for larger flat external surface designs that are good for conventional processes.

- AFM is not good to use for accurate edge processes that need zero radius.

FAQs

What are the applications of abrasive jet machining?

- The main uses of abrasive jet machining are as

- Cutting metals

- cutting of ceramics and glass.

- Shaping and profiling composite materials.

- Cutting stone, marble, and granite.

- Trimming and shaping aerospace parts

What are the typical applications of abrasive flow machining (AFM)?

- Radiusing.

- Polishing.

- Geometry Optimization.

- Deburring.