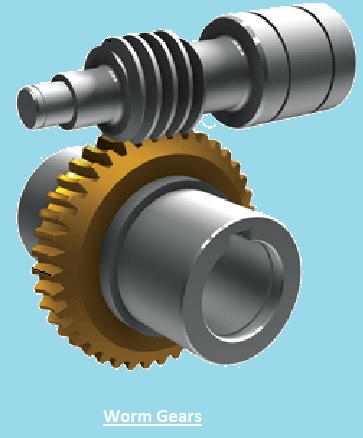

Worm gears are basic components used for mechanical systems for providing high torque transmission with compact design features. These gear systems have been used since they have certain screw-like features and also provide effective motion transfer while reducing space factors.

It is commonly used for heavy industry machines for providing high accuracy for tools in a reliable way. In this post we will cover details and features for worm gears and related factors.

What Are Worm Gears?

- Work gears made through using worm and gears that are called worm wheels come with nonparallel, nonintersecting shafts that are configured at 90 degrees.

- The worm is like a screw having a V-shaped thread, and the gears are like spur gears.

- Normally a worm is the driving component, and the worm thread increases the gear teeth.

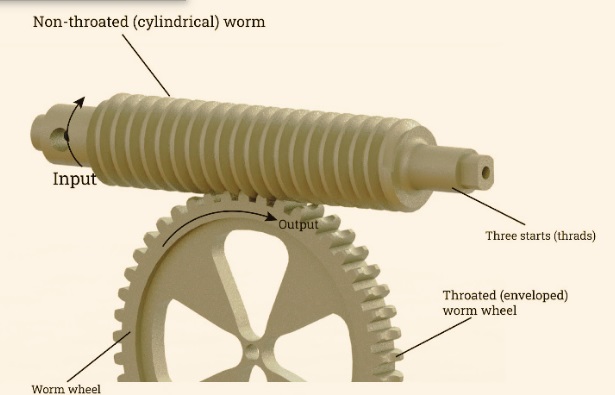

- Worm of worm gears, such as a ball screw, comes with a single start or many that show that the worm comes with many threads.

- The single full revolution of a single-start worm provides features with one tooth.

- As a result, a gear having 24 teeth causes a 24:1 gear reduction.

- The gear reduction for a multi-start worm is the same number of teeth as the gear divided by the number of starts on the worm.

History of Worm Gears

- The worm gearing is a very old system; it is used in water lifting devices and is part of the machine system.

- The Greek engineer Archimedes gets credit for early use of a screw-based mechanical system that makes the base for worm gear production.

- With time, worm gears face many changes, like from manually made wooden systems to high-accuracy metallic parts.

- The growth in metallurgy, lubrication, and machining accuracy makes worm gears more effective, advanced, and durable and gives them features to handle loads for different applications.

Worm Gears construction

Hobbing

- Hobbing is a basic process used for making worm gears, normally used to make high-volume productions. This process is accurate for gear teeth manufacturing with the use of customized hobs made for the required pressure angle and module pitch.

- Hobbing is a cold forging process where an accurate design of a gear is applied to a working component and makes accurate gear profiles good for different applications like gearboxes, machine tools, and conveyor systems.

- Hobbing tools called a hob, which is made with hard, structured, high-speed steel or carbide. Make a helical hob cutter.

- The use of high pressure, rotational speed, and cold forging helps to make worm gears with proper concentricity and high-tolerance features and, as a result, make a uniform finish for increasing the working life of components.

- The latest hobbing machines come with automated features and help to make gears of different shapes and sizes with accuracy for use in different medical devices and industries.

- This machine comes with two main spindles; one is used for clamping the gear blank, and the other is used for holding and rotating the hob. The result is synchronized cutting and a smooth tooth design.

Milling

- In the milling process worm gears are made through cutting gear teeth through applications of accurate gear cutters on special milling machines.

- Indexing table used for accurate position of gear blank single cut. The gear teeth are made through a rotating multi-edge gear cutter design for matching the required teeth design, which is called the gear profile.

- This process is applied for making standard and custom worm gears, for prototyping systems, and for small bulk manufacturing.

- The high-accuracy worm gear milling is based on cutter quality and proper setup since a small error causes a high effect on noise levels and transmission of power.

- Indexing is important for the milling process to make sure that the teeth are smoothly cut and provide accurate design features.

- The latest CNC gear milling provides high accuracy and speed for this process to fulfill the industry standard.

Grinding

- Grinding is a finishing method that uses different cutting edges working at high velocity for removing materials and making a highly smooth surface required for worm gears.

- Grinding is important for worm gears made with hardened steel and other materials.

- In this process, surface finishes and micro geometry is important for reducing friction, noise and wear at time of working.

- This process, also called hard finishing, refines gear teeth for final results and provides good tribological features, and longer working life for high loads

- For the grinding process, different latest multi-axis grinders tools used in combination of bonded grinding worms come with harder as compared to base gear materials

- machine colloborated with high precision infeed, vertical feed and lateral shifting motions for providing ess cutting for worm threads and gear teeth.

- Worm gears grinding also provides good load carrying features and efficiency and iis mportant for making gears used for vehicles and other motion control systems

Gears

- Worm gears come with specially designed worms and worm wheels that use helical gears made for transferring rotational power and motion between nonintersecting, normally 90-degreeshafts.

- These gears are made in 3 shapes: spur, left-hand helical, and right-hand helical.

- Worm-operated applications: left-hand or right-hand worm gears are important and used based on transmission direction for certain uses.

- The unique design features of helical worm gear teeth help to provide proper connecting with the mating worm wheel, reduce faults, and provide silent operations that are important for motion-sensitive industries.

- Main factors for material parameters of worm gears are bronze, steel, and certain alloys that are used based on proper wear resistance and configuration.

- The accurate lubricants and gear surface treatment are important for reducing wear and providing constant working features for required worm gear reducers.

Main parts of worm gears

Worm:

- The driving component that is cylinder-shaped comes with helical thread and provides rotational motion to the worm wheel.

Worm Wheel:

- The gear having certain design teeth that configure with the worm provides high torque transmission.

Shafts:

- It controls and rotates both the worm and the worm wheel.

Bearings:

- It reduces friction and provides support for radial and axial loads.

Lubrication System:

- It is good for reducing wear and providing high efficiency

Types of Worm Gears

The main types of worm gears are as

Non-Throated

- Non-throated worm gears are helical gears that come with a straight worm that is without a throat or groove drilled over the worm wheel. Gears are non-throated, and tooth connection is made at a single point on moving locations.

- The gears come with a single rotating point, so they face high wear and tear. Non-throated worm gears can easily be made for handling small weights.

Single-Throated

- Single-throated worm gears come with helical teeth designed over the worm for the contact line. This worm gear has features to provide high power without wear.

- The single set of worm threads makes a connection with the worm wheels for the worm gear. The worm needs a stronger design than the wheel, as there is one point of connection that causes high friction.

Double-Throated

- The types of single-throat worm gears and double-throat worm gears are different. Worm gears have two throats that are concave on both gears and the worm screw.

- The type of worm threads and teeth of gears are made for providing connection between wheel and worm.

- Worm gears come with 2 threads and have features to handle high loads. The double-throat design provides a strong connection between the gear and worm.

Features of Worm Gears

- It provides larger speed reduction without larger weight multi-stage gearboxes.

- It provides safety and load-holding features without extra braking needed.

- It is good to use for noise-sensitive conditions such as conveyors and robots.

- Throttled designs provide equal stress distribution and, as a result, durable features.

- It uses different materials like bronze and steel for providing controlling features of friction and wear.

Limitations of Worm Gears

- The main disadvantage of worm gears is low efficiency, since they have high frictional losses.

- As compared to spur or helical gears, which configure through rolling connection, worm gears are based on slinging connection for the worm and worm wheel.

- This siding feature causes high heat, resulting in energy dissipation, and also reduces efficiency.

- Due to that, the efficiency of worm gears is in the range of 40 to 90 percent based on structure, material, and lubrication.

- For handling these losses, some of the latest lubrication systems are used, and materials are used with low friction requirements.

- The lead angle optimization of the worm also reduces friction and provides good performance. But irrespective of these, working worm gears also provide higher energy losses than other gears. So not preferred where high efficiency is needed

Materials for Worm Gears

Bronze

- It has good mechanical features; bronze is used for making worm wheels. Bronze is a copper alloy and provides different features based on mixing with copper-like metals like nickel, zinc, tin, and aluminum. Worm wheels are made with tin bronze or aluminum bronze since they provide frictionless working.

Brass

- Brass is used for making wheel gears with soft features to avoid wear on the worm shaft, and brass worm gears feature working for light loads since brass is good to use for controlling stress.

Steel

- Steel worm gears and worm wheels are used, but the normal features are a steel worm gear and a bronze worm wheel.

- Steel has good durable features with tensile strength. but a steel worm wheel can be damaged and needs more time and cost for repairing.

Plastic

- Plastic worm gears are used for light load applications, like for low-torque applications such as vehicle or robotics applications.

- It will make noiseless operations when used for metallic worms and not need lubrication. Plastic worm gears are lightweight and have resistance to corrosion.

Stainless Steel

- Stainless steel worm gears made with 303 and 316 grade stainless steel. Stainless steel-made worm gears are good to use for damp conditions and resistance to oxidation and corrosion.

- Stainless steel worm gears are used for applications where hygienic conditions are needed, like in the food and beverage industry.

- Due to stainless steel worm gears, it comes with a smooth surface design with longer life features.

Worm Gears vs. Other Gear Systems

| Comparison Criteria | Worm Gears | Spur Gears | Helical Gears | Bevel Gears |

| Efficiency | 40%–90% | 95%+ | 95%+ high efficiency | 95%+ |

| Torque Transmission | High torque | Moderate | High torque | High torque for angular power transmission |

| Self-Locking Capability | Yes | No | No | No |

| Noise Level | Low | High | Moderate | Moderate |

| Wear and Tear | High | Low | Moderate | Moderate |

| Load-Carrying Capacity | Moderate | High | High | High |

| Application Suitability | Compact, precision systems,high-torque,

|

Simple, low cost power transmission | High-load and high-speed uses | Right-angle power transmission |

Advantages of Worm Gears

- Worm gears main feature is their capacity for producing high reduction ratios and providing high torque.

- For low- to mid-level applications, it is used as a speed reducer component.

- It also has a more compact design than other gear types because the reduction ratio is based on gear teeth.

- Worm gears are self-locking and good for lifting applications.

- The worm gears are limited to 30 to 50 percent efficiency since they have friction and heat produced with sliding motion.

- The worm and gear are made of different metals to reduce friction, such as the worm being made with hardened steel and the gears being made with bronze or aluminum.

- It operates noiselessly, and worm gears are good for elevators where noiseless operation is needed.

- Their soft material design helps to absorb shock loads in heavy machines.

Conclusion

Worm gears are a main component in industries and mechanical engineering systems since they provide proper transmission of torque, a locking system, and a compact layout. Either it provides difficulty for wear, or accurate material use, lubrication, and maintenance provide longer working life and effectiveness for different industries.