The check valve is a non-return valve that is a mechanical device that is used for one-direction motion of gas or liquid and controls opposite-direction movement. The fluid or gas flow direction is called the free flow direction, and the direction that opposes fluid movement is called the non-return direction.

Check valves are commonly used at homes and other locations. In this post we cover details for check valves and related factors. So let’s get started.

What is a check valve?

- The check valve, also called a non-return valve, reflux valve, or foot valve, allows fluid to flow in one direction and opposes the reverse direction.

- A check valve comes with two parts, which include one opening that allows fluid to enter and another part for releasing fluid.

- There are different types of check valves used for different applications.

- Check valves are commonly used at homes; they also come in different sizes and costs and are small and low-cost.

- A check valve operates automatically, and it is made with plastic or metal. The main feature of check valves is cracking pressure, the low differential upstream pressure between inlet and outlet when the valve works.

Check valve technical terms

Cracking pressure

- It requires a minimum pressure differential between the inlet and outlet of the valve where the first occurrence of flow is shown. Cracking pressure is also called unseating head or opening pressure.

Reseal pressure

- It is called the pressure differential between the inlet and outlet of the valve at the time of closing of the check valve when there is no visible leak rate. reseal pressure, also called sealing pressure, or closing pressure

Back pressure

- the pressure at the outlet of the fitting is greater than at the inlet or point upstream

Check valve working

- The check valve allows one-sided fluid flow and opposes it in the reverse direction. It comes with two ports, one used for incoming medium and the other to release fluid.

- It allows one-sided fluid flow, called a one-way valve or no-return valve. The main use of a check valve is to control backward flow.

- The check valve operated through pressure differential. It needed high pressure at the input side of the valve as compared to the outer side of the valve.

- If pressure is high on the outlet side, the valve will close. Based on valve type, each has a different working process.

- The check valve does not come with a handle or lever actuator for working.

- It is used for applications where backward flow is avoided. It is a non-return valve and is low cost.

Types of Check Valves

In-line check valve

- The inline check valve is a check valve that is like a lift check valve. This valve comes with springs that lift due to pressure on the upstream side of the valve.

- the pressure required on the upstream side of the valve for minimizing spring tension or cracking pressure. If pressure moving through the valve is less than cracking pressure, the spring closes the valve to avoid reverse flow.

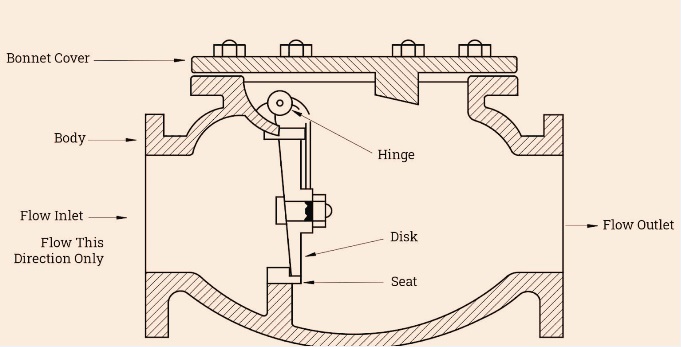

Swing Check Valves

- It is a common type of check valve. Its design comes with a hinged disc that swings open when fluid flows in the front side and closes for opposite flow.

- The valve is open when there is pressure at the inner side for managing cracking pressure, and the disc moves upward.

- When flow is not higher, the disc reseats to the closed position to reduce opposite flow.

- These valves are used where continuous and even flow occurs, like in pumping stations.

- Its maintenance is easy, and it is not good to use for high-frequency occurrences.

Ball Check Valves

- ball check The valve comes with a ball for closing the component. If fluid flows in the required direction, the ball lifts the valve seat and fluid flows. If the flow is in the reverse direction, the ball rolls back and stops the reverse flow.

- This valve is used for low-pressure applications and for thick fluids, like oil. A ball check valve is small and used where space is limited and not used for high pressure.

Lift Check Valves

- Lift check valves work like globe valves and come with a disc that moves its seat when fluid is in the inaccurate direction.

- The disc is configured on the valve body and lifts in an upward direction when no pressure exists.

- When flow is in the reverse direction, the disc gets the required position for stopping fluid back

- This valve is used for high-pressure applications and is good for applications where flow rate control is required.

- Their design helps to operate in high-pressure differential with needed pressure for raising the disc and is not good for low-flow applications.

Inline spring-loaded check valves

- This valve uses a spring system for closing, and the spring provides a fast response for flow direction. Changes reduce reverse flow. It is a compact design and connected in any direction and best for systems where low pressure is needed.

Diaphragm check valve

- The diaphragm check valve operated by a flexing rubber diaphragm configured for making a normally closed valve. Pressure on the upper side is larger than pressure on the downside; that is, the pressure differential that causes the check valve to open the flow.

- when positive pressure minimizes diaphragm flex to real conditions. This valve is used for respirators having an exhalation valve.

Butterfly check valve

- The butterfly check valve, related to the swing check valve, comes with 2 hinged flaps that are used as check valves for avoiding reverse flow.

- It is used for flow and does not provide one-way working.

Materials of Check Valves

The check valve is made with the use of durable materials that can handle high-pressure conditions. Normally made materials are as

Polyvinyl Chloride (PVC):

- PVC has a flexible design and resistance to corrosion. The PVC has a smooth surface for parts of the check valve to move easily.

Chlorinated Polyvinyl Chloride (CPVC):

- CPVC has the same features as PVC but has high temperature-bearing features.

Bronze:

- Bronze is used for making valves that are used for medium-level pressure and have a complex design and high resistance to corrosion.

Brass:

- Brass features are lower cost than bronze but have the same technical features as brass.

Cast Iron:

- Cast iron made valves used for hot and cold water, HVAC, and for applications where corrosion resistance is needed

Ductile Iron:

- Ductile iron contains 3 percent carbon and can be bent into different shapes. It has a stronger design than cast iron and is easily converted into a check valve.

Iron:

- iron-made valve used for oil, steam, and gas applications. It can handle different pressures and temperatures and also has a high cost with good features.

Stainless Steel:

- Stainless steel has high corrosion resistance, works well in harsh conditions, and is chemical

Polypropylene (PP):

- PP is used for making check valves that provide high resistance and have better features than PVC.

Polyvinylidene Difluoride (PVDF):

- It is used for applications where high resistance to acids and solvents is needed.

Some Problems with Check Valves

Water Hammer

- Water hammer occurs through pressure surge if there is an abrupt stoppage in fluid flow and the valve closes suddenly, resulting in vibrations. water hammer damage system and increases repairing cost.

- Water hammer can be solved through using a fast-closing check valve and avoiding pressure gauges and vibrations. For managing this issue, use a silent check valve.

Reverse Flow

- Reverse can damage the valve and result in the pump moving in the wrong direction. This error was solved through tight fitting and quick check valve closing. The spring helps the check valve to move to avoid reverse flow.

Oversizing

- Check valve faces chattering as a result of opening and closing the valve frequently and as a result of an ofoversied valve. Accurate sizing is important for installing a check valve for proper fitting. The disc needed to be stable for opening and making a complete seal at the time of closing for avoiding fluttering.

Installation

- Improper installation of the check valve causes different errors. For connection of the valve, first check capacity, positioning, and orientation.

- Installing a check valve close to the pump can cause turbulence and damage to the valve.

How do you choose the right check valve?

Flow of fluids

- The main factor is the flow conditions that a certain system needs. If you have non-pulsating flow, use a swing check valve. For non-steady flow, use a ball check valve that has a high frequency of motion and works well at low flow rates.

Pressure

- Cracking pressure required for opening the valve needed to be chosen for the given system. Such a pressure system of oil and gas uses high cracking pressure for controlling reverse flow. For low-pressure applications, use a valve with low cracking pressure applications.

Material

- • The materials of the valve also help to use the valve for certain applications. like the water system, uses usesstainless steel. In some applications where chemical materials cause corrosion, PTFE or alloys are used for avoiding corrosion.

Installation

- The dimension of any system also defines valve type and certain dimensions. For limited space applications, use a ball check valve, and use a lift check valve for larger spaces since it moves vertically.

FAQs:

What is the working of a check valve in a water system?

- When inlet pressure crosses outlet pressure of the water system, the check valve helps water to flow in one direction. If pressure levels are in the reverse direction, stop water flow.

Why are check valves used in industries?

- In industries, check valves stop backward flow of fluids and avoid damaging tools.

Can check valves stop working?

- • The check valve can be damaged, which can be due to leaking, and motion of fluid occurs with reverse flow. Proper monitoring can avoid damage.

What are the selection criteria for a check valve suitable for my specific application?

- follow different parameters like temperature and direction. Get the services of expert valves for choosing the right valve for certain applications.

How frequently do check valves need maintenance?

- It is based on valve type and features. It is normally referred to inspect the valve for high usage and also check the working after one year.

What are common check valve faults?

- • The main faults for check valves are water hammer, reverse flow, sticking, leakage, and damage to any part.

Does a check valve stop water hammer?

- Yes, but it needed high-speed operations like a spring-actuated check valve. that control pressure surges, which produce vibrations in fluids