Flat belts are basically power transmission belts that are flat in design and made with leather, rubber, and synthetic composites. It is part of different machines that use conveyor systems and it is also used for machines that transfer rotational power.

Flat belts are mostly used for high-speed machines since they provide positive grip. In this post, we will cover details of features for flat belts and their importance in industries.

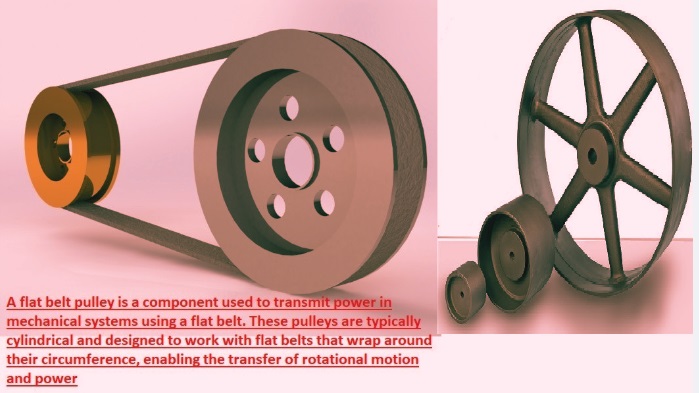

What is a Flat Belt Pulley?

- The flat belt pulley is part of a mechanical system that is used for power transfer between shafts.

- The pulley made has a design that operates with a flat belt wrapped over pulley wheels, providing easy motion, and has features to transfer over longer distances.

- If we make a comparison between the V-belt system and flat belts, then we find that flat belts are good to use for low-torque applications and high-speed requirements and good to use for low-weight operations.

- flat belts made with different materials like leather, rubber, or synthetic polymers.

- These materials are used since they provide a strong grip and flexible design that operates the system in a smooth way and reduces wear on the belt and pulley.

- flat belt parts for low-power loads and high-speed functions.

- Flat belt pulleys have a strong design, have fewer components, and are easy to connect.

Benefits of Flat Belt Pulleys

noiseless working,

- A flat belt also has quieter operation than other belt types. So it is good to use for applications that require quiet operations. This system does not have any teeth or grooves in its design, so less friction exists between the belt and pulley.

low cost

- The main features of this pulley are low cost and easier maintenance than other belts, such as toothed ones. They are a low-cost option for light-duty applications.

Versatile design

- A flat belt pulley can be used for different applications, so it is versatile. It is part of machines used in agriculture and factories that operate on conveyor belts and provide smooth operations.

uniform power transmission

- • The flat design of the belt provides continuous power transfer for longer distances. This smooth movement is good for reducing vibrations since non-uniform power transmission occurs and can affect any delicate part.

Longer working life

- Its simple design and smooth power transfer make for a longer working life than complicated belts. Their longer working life makes them best to use for different projects if they are getting continuous maintenance.

Types of Flat Belt Pulleys

Fast and loose pulley

- The use of a fast and loose pulley on the shaft helps to provide easy switching of machines. The free pulley moves on its own, and the fast pulley is strongly fixed in connection with the machine shaft.

- If the machine does not require power transmission, the belt shifts to the loose pulley. The belt was staringly operated with a fast pulley.

- the controls of other machines that make connections with the line shaft that are affected by one stopped machine

- • A loose pulley comes with a cast iron-made bushing that has a collar at one side for managing axial motion. The rim used for the fast pulley has a larger size as compared to the loose pulley, which causes the belt to move slowly on the loose pulley.

- A loose pulley comes with a longer hub for controlling friction and uses an accurate value of lubrication.

Paper Pulley

- • A paper pulley made with compressed paper fiber and a central design has a metallic composition.

- This pulley is part of a belt transmission, like in electric motors, that has a short distance from the central to the central shaft.

Wooden pulley

- This type of pulley is low weight and has good friction resistance. Their weight is two-thirds of the cast iron pulley, and the maples used for making this pulley are connected with glue.

- These pulleys come with varnish coatings that minimize the effect of moisture.

- • The wood pulley comes with a solid design and has an iron hub connected with screws or comes with moving bushes that prevent friction.

- This pulley is used in motor drivers where the arc between the pulley face and belt is restricted.

Steel pulley

- Steel sheets make steel pulleys that make strong designs. This pulley operates at high speed and weighs less than an iron pulley with the same features.

- It has a coefficient of friction for a leather belt that is high according to the cast iron pulley it produces.

- two plates of steel pulp connected since the clamping process of the hub manages the shaft pulley.

- It has variable bushes on shafts having different lengths.

Cast Iron Pulleys

- It is made with cast iron, so it is known as a cast iron pulley. rim connected on the web through using arms, spokes.

- It has an elliptical cross-section, and the arms are in a straight design. A cast iron pulley comes with circular arms.

- Cast pulley arms have high pressure and can be damaged when they shrink in casting.

- Cast iron pulley has two further types; split pulley is easy to use when connected to the pulley on the shaft that comes with the pulley.

Limitations of Flat Belts

- Either flat belts A pulley has many advantages but also has some limitations.

- They are a less flexible design than V-belts or round belts. So flat belts are not used for variable power requirements applications.

- Its design is more complicated than other belts, since it has a difficult installation and maintenance.

- Flat belts are designed for high-speed applications but do not work well for low-speed applications.

- These belts have high vibrations that cause noises and damage the belt and other connected parts.

- Its working life is less than other belts, so it does not work well for applications that need durability.

- They have a lower power capacity than other belt types, which makes them less useful for high power transmission.

- It needed frequent maintenance which increased downtime.

- Flat belts are more costly than other types. Flat belts are also used for straight-line power transmission and do not work well for curved paths.

- Flat belts also need lubrication that reduces friction and any wear that causes contamination.

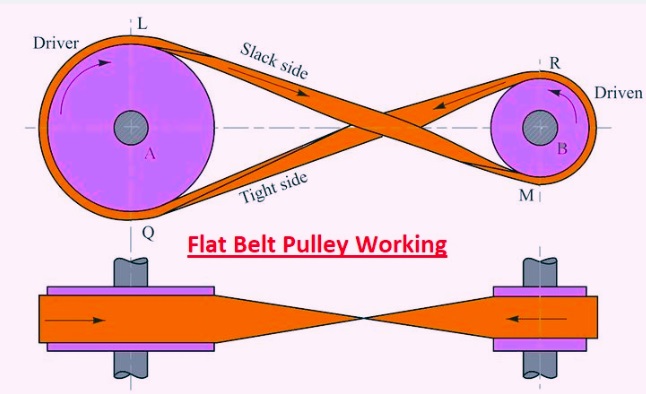

Flat Belt Pulley Working

- Flat belts are drive systems that transfer rotational power through a belt and pulley.

- They have noiseless working and low vibrations, and the top component of the belt has high tension when it rotates.

- Friction between the belt and pulley affects power transmitted and controls slippery features and belt work at low speeds.

- The camber method is used, in which a flat belt is warped through a bow shape, and the camber is the outward edge, and the concave middle is called the bow.

- In flat belts there is a mixture of rubber and reinforcing fibers, and natural rubber has good elasticity, and synthetic rubber has good resistance to heat and ozone.

- Flat belts use polyester fiber and Kevlar fiber, which increases belt strength, and filler, which is used to increase the working life of belts.

How to Choose a Flat Belt Pulley

Some factors must be considered before using a flat belt pulley.

Belt Material

- The materials of the belt affect longer working life and the strong grip. Based on applications, different materials are used for belts, like rubber, leather, and synthetic belts, which have different strengths.

Pulley Diameter

- Pulley dimensions affect torque and speed production. A small-sized pulley provides high speed, and a larger pulley has high torque. So choose pulley diameter according to requirements.

Length and width of belts

- Set the belt and width according to the pulley that minimizes slippage and makes a strong grip.

- The improper belt length minimizes efficiency.

Shaft alignment

- Flat belts handle high levels of misalignment and make sure shafts accurately control high wear on the belt and pulley.

- Misalignment also affects the efficiency of the system and damages the belt.

Tension Adjustment

- Accurate tension also affects the working of the flat pulley system. High tension causes damage for the belt, and low tension causes slippage.

conclusion

A flat belt pulley is simple, low-cost, and has a longer working life than other mechanical systems. It has noiseless operation and high efficiency for longer distances with low wear, so it is used for light- to mid-level applications.

If we provide proper maintenance, accurate alignment, and proper belt tension, it causes the flat belt pulley system to work at good performance for a longer time.

read our related guides

- How to Check Tire Tread Depth

- What is Check Valve: How Check Valves Work

- What Is a Throttle Body? Cleaning, Features, uses

- When Should You Use Your High Beams?

- Difference Between Drum Brake vs Disc Brake

FAQs

What is the purpose of a flat belt?

- flat belts used in textile machines for providing power to spindles, needles, and other components. In textile machines, flat belts are used for many operations, like controlling processes and power transmission.

Which is better, a V-belt or a flat belt?

- The preferred V-beltson flat belts have a strong grip and traction. V-belts come with a V-shaped cross section that fits in a matching V-groove pulley.

- These features provide strong power transmission through making a larger connection area between the belt and pulley.

What is a flat belt conveyor used for?

- Flat belt conveyors are used in different industries, like medical, food processing, and packaging. Flat belt conveyors are used for handling products, automation, robots, and other industries.

What is the maximum speed of a flat belt?

- Flat belts are used according to belt type speed, which is 80-100 m/s.

Define a flat belt pulley.

- flat belt Pulleys are part of a transmission system that operates opratedwith flat belts, with high-speed and low-power applications in the textile industry and computer printers. Flat belts are also parts of conveyor systems.

What are the features of flat belts?

- flat, used for transmitting power through low losses, and more effective than other belts. flat belts made with leather or rubber that have high resistance to wear and tear

How do flat belts stay on pulleys?

- Flat belts regulate on pulleys without using flanges. Crowned pulleys are used for proper centered tracking on the pulley.The crowned pulley comes with a hump in the central design that is tapered towards the edge.

What are the disadvantages of flat belts?

- It does not work well for high-power transmission.

- It does not provide an accurate velocity ratio.

- It does not work well for short distances and covers larger distances.

What machines use flat belts?

- Conveyors, machining tools, and heavy industrial machines use flat belts.

What happens when a belt pulley is faulty?

- If the pulley gets worn, that faces difficulty for maintaining tension on the belt. The belt can be loose and knock through other parts and result in noise due to slapping. So use a new pulley and also change the belt according to damage.