Cutting tools are instruments that are used for material shaping, removing, and carving at different times in manufacturing processes, like milling cutters and drills. mechanical and different metallic parts machined with the use of different machines.

Tools used for removing layers of the surface of different parts that make the required shape are called cutting tools. The materials used for cutting tools should be harder compared to the materials where the cutting operation is performed. In the machining process, a cutting tool is a hard metallic tool that is employed for shaping and removing materials on a metallic component with the use of shear deformation. In this post we cover detailed features for the cutting tool and its practical working.

What Is a Cutting Tool?

- In the machining process, the cutting tool is a hard metallic tool that cuts, shapes, and removes materials from the working component through the use of machining tools and also abrasive tools through shear deformation.

- These tools are made with metals. Single-edge cutting tools made with hard metallic alloy are converted into certain designs for certain parts of the turning process and make finished machined components.

- Single-edge cutting tools are part of different turning processes that are performed with a lathe machine, where they have different sizes and alloy compositions according to the materials being turned, their size, and their type.

- With the use of a tool post, we can make these cutting tools static and cut materials in certain shapes.

- Single-edge cutting tools cut materials through shaping machines and planning machines that remove materials through the cutting edge.

- Milling and drilling are multipoint tools. Drilling makes holes in the working component. Drill bits come with two cutting edges that are ground at 2 same tapered angles that cut materials through rotational force applied downward.

- End mills also cut materials through rotational force. These tools are not made for putting holes in working components. It cut through horizontal shear deformation where working materials were put in the tool in a rotating form. That called the tool path that defines the through axis of the table that holds the working component at a certain point.

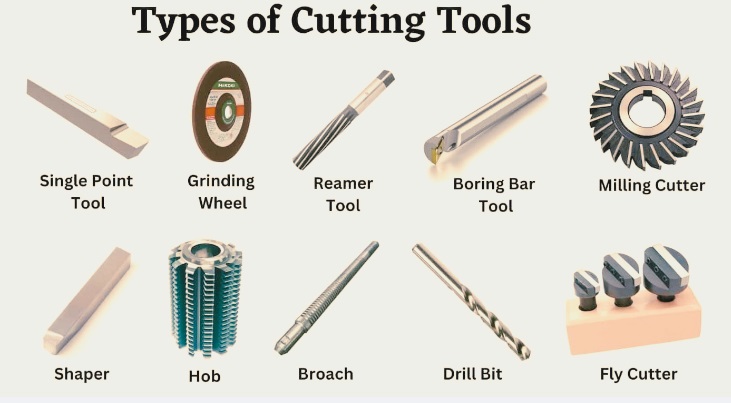

Examples of cutting tools

Grinding wheel

- This tool is an abrasive tool that is used for grinding machines for grinding operations.

Single Point Turning Tool.

- It is used in a lathe machine for performing turning operations.

Broach

- The broaching tool is a machine tool that performs surface machining of cylindrical surfaces. Broaching machines come with different cutting tools connected in an axial and radial way, configured in a rod-type design external area.

Fly cutter.

- This tool is used for performing fly milling on a milling machine.

Sharper

- The working material gets a certain shape with high accuracy, and it is performed through a shaping machine.

Drill

- A drill is used for making holes in materials and comes with an edge on the tip and a helical groove that clears shaving drills. It is also called a cutting tool since it has different types and shapes that perform basic to special machining tasks.

Mill

- The milling tool comes with a different edge on the external area cylindrical structure, and it performs cutting functions through rotation.

- It is used in milling machines and CNC machines. Its blade is made with high-speed steel, carbide, and diamond.

Reamer.

- Reamer tools are used for enlarging holes already made and provide a high level of ofaccuracy. It is like a cutting tool and comes with a blade made with carbide and steel. Its cutting edges can be different based on the application diameter of the hole. Through using a step reamer, different processes can be performed through a single reamer.

Planer.

- It is a shaper tool; it uses heavy-weight materials that move for shaping in the cutter.

Types Of Cutting Tools

Single-Point Cutting Tools

- The single-point cutting tool is made with a single primary cutting edge for removing materials in one pass.. Different processes, such as turning, planning, and shaping, performed with a single-point cutting tool.

- It is made with hard structure materials like ceramic, high carbon steel, etc., but the existence of one cutting edge can break and also affect the material removal process.

- that stop working, and we replace them with new cutting blades if they break. single cutting edge tool used for single-point instruments, like a single-bladed reamer, that helps to remove materials.

- The main features of this tool are low cost, simple design, and less time for working. Its disadvantage is that it remains connected with machining working materials.

- It has a short working life due to high wear, and its temperature increases fast due to regular connection.

- Due to that, wear increases on the tool and affects the surface of the tool.

Double Point Cutting Tool

- The double-point cutting tool comes with two edges that cut with a single motion. The single-point cutting tool comes with one cutting edge, and the double-point tool has two edges.

- The multi-edge cutting tool has more than 2 cutting edges that provide machining functions in one pass.

- A cutter normally has two types, but a double-point cutter comes with multi-point cutters.

- The cutting edge is the intersection of the rake face and flank, and the double-point welding tool comes with two rake faces and two flanks.

- The basic example of a double-point cutting tool is a drill, which comes with more than 2 cutting edges, with basic metallic cutting drills, and comes with 2 cutting edges.

Multi-Point Cutting Tools

- The multi-point cutting tool comes with more than 2 cutting edges that work simultaneously for one machining pass.

- A cutter having two edges is called a multi-point tool, not a double-point cutter.

- The number of cutting edges on this tool is 3 to some hundred, according to design.

- As a single-point cutting tool has one edge for material removal, a multi-point tool uses usesdifferent edge at the same time. that helps to remove materials effectively.

- A multi-edge tool operates with higher speed than a single-edge tool. Since heat is generated when cutting with different blades, the result is that the tool works worklonger and has low wear.

- The multi-point cutting tool has many features, like each tooth facing a low chip load, that provide high speeds and high material removal rates, resulting in increased efficiency.

- Less wear and low cutting temperature cause longer tool working life.

- but also has some limitations, like each tooth faces different loads, which produces noise, vibration, and tool damaging

Materials of cutting tool

- When the machining process is performed, the cutting tool makes a connection with the working component and faces high cutting temperatures and intense rubbing.

- Cutting materials needed to have features for high cutting temperature handling and cutting force.

- It is important that tool materials have high hardness, high hot hardness, high strength, a high melting point, and also chemical strength with a high cutting temperature.

- • The hardness of the tool needed to be more than 2 times the hardness of the working materials.

- • A coating applied on the tool for increasing required features; coated tools make reshaping difficult through grinding in case of worn edges for longer uses.

- Commonly used materials for cutting tools are

High-Speed Steel (HSS):

- It makes different tools that come with different elements, such as tungsten, chromium, and vanadium.

Carbide:

- Also called tungsten carbide, this cutting tool comes with tungsten carbide and cobalt as a binder.

Polycrystalline Diamond (PCD):

- the synthetic materials employed for the cutting tool. This material is made with sintering diamond powders through a binder.

FAQs

What is a cutting tool and what are its types?

- Linear cutting tools come with tool bits and broaches; rotary cutting tools are drill bits, counterbores, countersinks, dies, reamer cold saw blades.

What are examples of cutting tools?

1. Shears.

2. Scissors.

3. Snips.

4. Rotary Cutter & Cutting Mat.

5. Seam Ripper

What are cutting tool materials?

- cutting tools are used for making cutting tools that are part of the machining process, like drill bits, tool bits, and milling cutters, but they are different from punches and knives.

- Cutting tool materials needed have a harder design than other working materials and handle high temperatures.

What is cutting, and what are the types of cutting?

- The main types are mechanical cutting, abrasive cutting, thermal cutting, and electrochemical cutting. Each uses different metal cutting machines and tools.

What are the two most common types of cutting tool materials?

- cutting tools made with different materials that have features of high load handling at the time of the cutting process and provide a sharp design for shear materials. The commonly used materials are high-speed steel (HSS) and solid carbide.

Why are cutting tools made of class 6 metal?

- cutting tools made with metals since they have good physical and chemical features. Some metals, such as high-speed steel, carbide, and cobalt, are used since they have high hardness, wear resistance, and good cutting features.

What are the two types of cutting machines?

- Manual Cutting.

- Semi-Automatic Cutting Machine.

- Fully Automatic Cutting Machine.

What materials are used in lathe cutting tools?

- High-speed steel has different components: carbon, vanadium, tungsten, and chromium. Cutting tools made with these materials have higher strength and resistance for wear/heat.