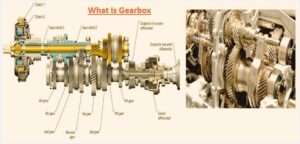

A gearbox is a group of gears in a casing found in different vehicles. A gearbox is also called a transmission. Different vehicle engines have high operating and idle speeds; the transmission helps machines to operate in an effective way and control speed and stop.

The main function of gearboxes is to transfer energy from one rotational power supply to another and to parts of vehicles and heavy machines. Here we will cover details for gearbox features and related factors. Let’s get started.

What is the gearbox?

- The gearbox is a mechanical structure that comes with gears and gear trains. Its main function is to set output speed and motor torque for fulfill the requirements of projects.

- Through varying gear ratios, the gearbox increases torque and reduces speed, and the reverse process occurs according to the requirement.

- A gearbox is basically a gear system that changes torque and speed between the drive, like a load, and the motor.

- There are different types of gears in gearboxes, like bevel and helical gears, worm gears, and planetary gears.

- gear configured on a shaft that is compatible with roller bearings and rotates over it.

- A gearbox is a mechanical device that transfers energy from one module to another, increasing torque while reducing speed.

- Gearboxes are part of different applications, for example, machines, industrial devices, conveyor belts, and power applications, where rotary motion is used for speed and torque changes.

Parts of the Gearbox

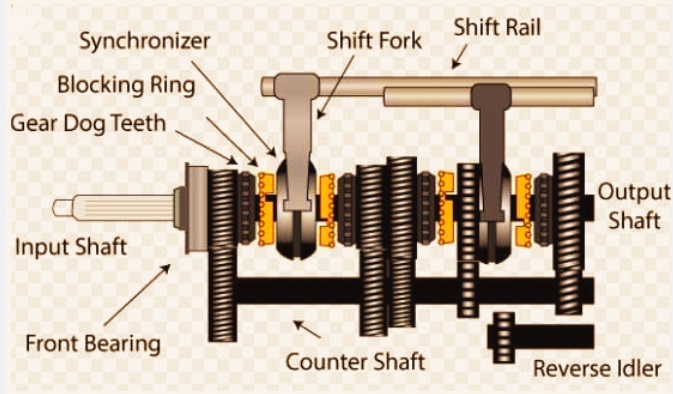

Main Shaft

- This shaft is used as an output shaft for the gearbox, which lies parallel to the layshaft and the front side of the clutch shaft or engine output shaft. This shaft is used for changing gears and is connected with the gear lever.

Clutch Shaft

- This shaft handle engine output and sends it to the gearbox; this clutch shaft provides engagement and disengagement of engine output.

Countershaft

- The shaft output of the engine is sent to the main shaft with continuous gear meshing on the layshaft to the gear through the clutch shaft.

Gears

- Gears are connecting gears. They have teeth that move and mesh with other gears on different shafts and transmit circular motion between two different locations shaft includes helical gears, bevel gears, and spur gears

Synchromesh Devices

- It is a special tool that is used in an advanced gearbox that shifts gears smoothly by providing main shaft, clutch shaft, and lay shaft speeds simultaneously, so they do not move on the shaft for changing gears.

Dog Clutches

- It is used for old gearboxes, such as constant mesh gearboxes, and prevents gear sliding on the shaft for shifting or meshing. It slides on the shaft for changing gear.

Gear lever

- This lever type is controlled by the driver for changing gears; the lever moves in a certain motion direction.

Working Principles of Gear Box

- • The gearbox comes with different-sized gears since different torques are required on wheels based on road conditions, load, and terrain. There is a need for high torque when moving uphill compared to a straight road.

- First gear is larger in size than the other gears, which provides high torque at low speed.

- Gears come in different size ratios from first to last ratio, which provide different pulling features and speeds.

How do gearboxes work?

- • The constant mesh gearbox comes with a driveshaft connected with gears that mesh with the gear configured on the layshaft.

- Lay shafts come with different gears that are designed in a mesh of gears.

- gears not directly connected with the main shaft and easily rotated.

- Dog clutches are used for controlling gears and splined with a basic shaft, which provides rotation.

- Dog clutches also come with friction material that makes their connection with the gear on the main shaft.

- When we push the gear stick during driving, the selector fork moves the connected dog clutch to make a connection with the gear.

- Finally, the clutch and main shaft move through the selected gear speed.

Types of Gearbox

There are two basic types of transmission, or gearbox, used that

- Manual transmission or manual gearbox

- Automatic transmission or automatic gearbox

Manual transmission or gearboxes

- The manual transmission gearbox that has been used in some vehicles has a low cost. In this gearbox, limited gears are used that have a maximum of six speeds and one reverse and manual shifting of gears is done through pulling and pushing the gear lever.

- In this transmission process, a clutch is also used.

Some manual transmission types are

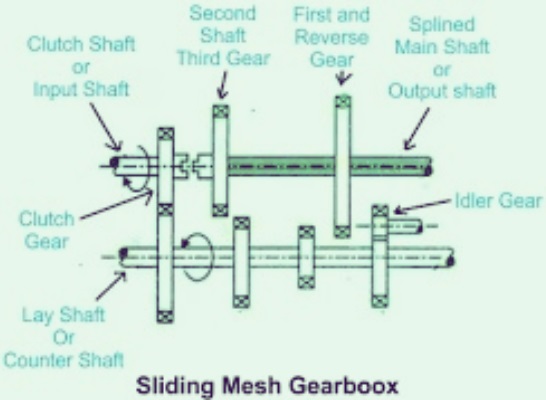

Sliding Mesh Gearbox

- It is a gearbox that is an older type, and it does not have a layshaft and a main shaft in mesh, just a single gear in continuous mesh that has a gear on the clutch shaft that moves the layshaft and gears meshing through a proper gear on the layshaft. where the left or right sliding of gears on the main shaftSynchromesh Gearboxsynchromesh gears are used in advanced cars, which synchronize the mesh gear rotation. This gear control reduces the chances of gear-clashing and provides easy gear shifting. This gearbox is like a constant mesh gearbox.

- It comes with synchromesh tools, where two gears that need to engage first make a frictional connection through getting speed, which makes assembly easy.In some vehicles, the synchromesh process does not fit on all gears, but on the upper part of the gears.In some conditions, reverse gears do not exist for synchromesh devices, since they engage when the car is not moving.

- If the lever is shifted, the synchromesh cones come together in connection, like the same cone on the pinion.Due to friction, the rotation pinion is isready for rotation with the same speed as the synchromesh unit.For positive drive, extra motion of the gear level provides coupling for overriding different springs, and loaded balls and coupling make a connection with the dogs’ pinion ride. The synchromesh units and pinion move with the same speed for the required movement before connecting the dog teeth, so the cones come with providing the synchronizer and the pinion with the same speed.

Constant Mesh Gearbox

- In this type, all gears of the main shaft make connection to the layshaft gears through constant mesh.

- • A sliding dog clutch is put in the center of the clutch gear and 2nd gear; the other is configured between first and reverse gear.

- Gears do not depend on the main shaft being splined. The dog clutch skids on the main shaft for rotation. Complete gear on the layshaft is fixed on it.

- If the left-hand dog clutch is taken for a skid to the left through the gearshift lever, make a connection to the clutch gear and provide high-speed gear.

- If the left-hand log clutch makes a connection with the 2nd, it provides 2nd gear speed.

- Through shifting the right-hand dog clutch from left to right, we will have first and reverse gear.

- It makes a constant mesh and is safe from damage, avoids gear clashing, and does not cause any sound for engaging and disengaging.

Automatic Transmission or Gearbox

- This type of gearbox is used for high-end cars since it has a high cost. This gearbox provides an infinite gear ratio through accelerator pressing for this select drive mode, either forward or reverse, drive, park, neutral, or sport. The suggested ratio with the timing of the mesh set automatically.

- The automatic gearbox does not use a clutch pedal, so cars with an automatic transmission have two pedals.

Automatic transmission also has subtypes.

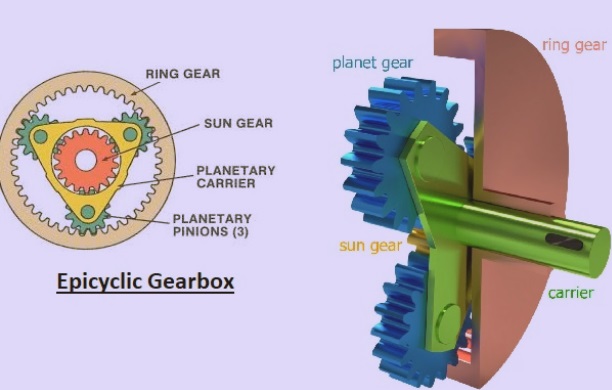

Epicyclic Gearbox

- Sun and planetary gears with an annular ring and a carrier operated this gearbox.

- The clutch shaft is connected with a sun gear that is in constant mesh with different planetary gears that move freely on an axis and have constant mesh through a ring gear that comes with teeth in the internal design, and rotation of the planet gears is performed through carriers that are connected with the main shaft

- The clutch shaft is connected to the sun gear, which is in constant mesh with the number of planetary gears, which freely rotate on their axis and are in constant mesh with the ring gear, which has the teeth at its inner side. The rotation of the planet gears is carried by the carrier used, which is connected to the main shaft.

- In this transmission, gear shifting or different gear ratios are achieved by getting any one of the gears—the sun gear or planetary gears—through the breaking band that is operated by the accelerator pedal.

Hydraulic Torque Converter

- It is a special category of automatic gearbox whose working is based on fluid coupling. It provides different speeds and gear ratios through using a turbine, impeller, high-compressed fluid, and stator through controlling the accelerator pedal.

- Impeller of the torque converter connected with engine shaft, turbine with output shaft, and the stator configured between them for direct fluid flow

Importance of the Gearbox

- • The gearbox helps to control the slow and fast speeds of your car. so it controls engine speed in a 4:1 ratio for cars and higher for trucks and other heavy vehicles.

- It provides torque and engine speed transmission based on demand.

- • The gearbox also flexibly limits the speed and torque of the internal combustion engine at a larger scale.

- It also provides relative motion between driving wheels and the engine as a result of road spring flexing.

- It also makes leverage between the engine and driving wheels for variations.

Application of the Gearbox

- It is used for providing high torque for engine turning acceleration and hill climbing.

- It increases the relative motion between the driving wheels and the engine.

- It helps to move the driving wheels at different speeds.

Basic Gearbox Configurations

Helical Gearbox

- Helical gearboxes work with helical gears, which come with angled teeth that give smooth and noiseless working. It also provides high-speed features.

Coaxial Helical Inline Gearbox

- Coaxial helical inline gearboxes come with input and output shafts configured to provide high efficiency and a compact design.

Bevel Helical Gearbox

- This gearbox comes with bevel and helical gears, provides high efficiency, and changes the direction of power transmission.

Worm Gearboxes

- It uses worm gears and worm wheels that deliver power. This feature helps to provide high torque and is used where low speed is needed.

Planetary Gearbox

- This gearbox comes with a sun gear in the middle, planet gears, and ring gears that deliver power.

- This design increases efficiency and compactness and is mostly used where high torque and precision are needed.

Manual vs. Automatic Car Gearbox

| features | Manual Gearbox |

Automatic Gearbox

|

| Operation | This type of manual transmission uses selective gear shifting operated by the driver through the use of a clutch and gear gearstick based on driving requirements. |

This gearboxes control all gear automatically based on throttle and speed.

|

| Clutch Mechanism | has dry single plate clutches for manual cars that operate with the pedal. |

it uses fluid coupling modules, such as torque converters than plate clutches.

|

| Gear Layout | it has 4to 6 forward gears and reverse one gears |

it has more gears about 10 forwardr ratio that make high complicated planetary gear arrangements.

|

| Efficiency | it has low power losses over low mechanical connection and requires low maintenance. |

it uses high power with extra fluid coupling and not have hassle

|

| Driving features | manual transmission based on gear shift timing and provides perceived control. |

Automatic cars are easy, helping the driver to steer and accelerate.

|

Conclusion

gearbox of any type is make bridge-like design between the engine and the wheels in vehicles.