A needle valve, also called a plunger valve, is a regulating valve that provides accurate control and regulates water flow and pressure. It provides high accuracy through accurate shaft motion that causes the gearbox to move the piston tube in a sliding movement in the direction of the opening or closing position, according to the control system demand. Here, we will cover the details and features of needle valves and their related components.

What Is a Needle Valve?

- A valve is a device that lies over a pipeline, and its function is to set air flow or liquid that moves for a longer path.

- Valves come with different types and features according to their working features.

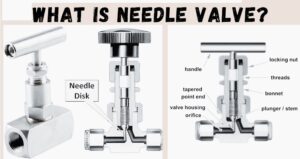

- The needle valve comes with a small port and a needle-like plunger that moves in an upward and downward direction in the enclosed port.

- The up-and-down motion of the plunger port provides accurate flow control.

- Some valve designs come with two setting features that are open and closed, but needle valves and other valves have half-open, fully open, or barely open designs that provide a high level of accuracy.

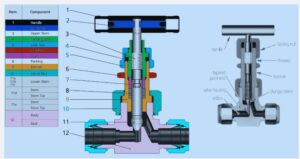

needle valve construction

- needle operated with tapered pin for opening area for accurate and easy flow control

- flow controlled and regulated through use of a spindle. The needle valve comes with a small orifice and a long tapered seat, and a plunger connected at the screw end that accurately fits the seats.

- The plunger is retracted when the screw is turned, and flow between the seat and plunger occurs, but the plunger needs to be retracted and the fluid impeded.

- It takes different turns for the fine-threaded screw for retracting the plunger, providing accurate flow regulation.

- The working of the needle valve is like the vernier effect of the ratio between the length and diameter of the needle. or the difference between the diameter of the seat and the needle.

- The long axial travel provides small and accurate changes in a radial fashion.

- A needle valve is also part of the vacuum system for providing accurate gas flow at low pressure, like for filling gas-filled vacuum tubes in gas lasers.

Needle Valves Working

- working of the needle valve such that needle of the valve is depressed to provide or stop flow of fluid through tube.

- In the working of this valve, it has a whole host of intricate components that fit with each other and work due to the needle and seat.

- • The needle is a conical design plunger that contracts or releases from the channel for providing controlled flow.

- • The seat is a space where the needle puts a channel where fluid moves.

- Needles and seats are made for accurate fitting with each other.

- So when the needle connects and is completely depressed, no air gaps for releasing fluids exist.

- The needle valve also has a handle on the external area, that bar handle or round handle that helps to use for easy holding and connection with the stem.

- design of needle valves such that, internally, the needle fits in the seat and has a thread as a screw for simple working

- For working of the needle valve, rotate the stem through the holding handle which helps to get easy rotation.

- When the needle rotates, the threaded sides turn, and the needle is raised or lowered from the seat.

- Due to threading, the change in needle depth for each turn is low.

- that provide high accuracy, since the needle is raised or lowered at a small angle. So the complete component will have high pressure and create pressure in a small area when the flow stops.

factor for selecting a needle valve

Some parameters help to select the needle valve accurately.

material

- Commonly used valve housing materials are stainless steel and brass, which also have high chemical resistance.

Stainless steel

- Stainless steel has high corrosion resistance, strength and a durable design.

- stainless steel needle valve casing good for handling high pressure, like about 690 bar (10,000 psi), and the temperature range is -254°C to 649°C (-425°F to 1,200°F)

- It provides corrosion resistance when working in chloride conditions.

- It is nonreactive and good for the food and chemical industries.

- applications where low pressure and temperature exist, brass can be used

Brass

- Brass is used for making needle valve casings for moderate pressure and temperature conditions.

- Brass needle valve good for hydraulic systems, high-temperature conditions, gas pipes, and water.

- It can handle pressure of about 207 bar (3,000 psi) and temperatures from -198°C to 204°C.

- Brass has good machining features for accurate manufacturing processes and tolerances with a low-cost option as compared to stainless steel.

- It is good to use for corrosive mediums and is mostly used for drinking water applications.

- brass, not used for distilled water, acids, or chlorides, and preferred for areas where high corrosion exists

valve pressure

- Before using the valve, it is good to check the application pressure requirements.

- Accurate pressure rating helps the valve bear system conditions without damage, avoids leaks, and ensures safe operations.

- Normally, a needle valve can handle a pressure of about 300 bar at 20𐩑C. 𐩑C .

dimension

- Needle valves come with different port and orifice sizes. Connection ports come with male and female parts.

- Normally threaded standards are National American Pipe Thread, BSP, or ISO standards.

- Commonly, the needle valve dimension range is 2 to 12 mm.

- Try to use accurate port size and orifice size for providing effective flow and system working with low leakage.

Temperature range

- Needle valve preferred for high- and low-temperature conditions, but before using, make sure to define valve housing sealing materials handling conditions.

- Sealing material is important because it affects valve overall temperature conditions that maintain quality and leak control.

- NBR seals are good for a temperature range of -40°C to 120°C, and their common uses are in fuels and oils.

- Teflon-made seals handle a temperature range of -20°C (-4°F) to 200°C (392°F), so they are used for applications where chemical resistance and high temperature stability are required, like chemical processing.

Types of Needle Valves

Straight Needle Valves:

- It is a commonly used needle valve. It comes with a linear and simple design that provides an easy control process.

Angle Needle Valves:

- This valve comes with some angle designs that provide spacing features and provide fluid change direction

Multi-turn Needle Valves:

- This valve comes with different turns for closing and opening features. It provides accurate control and can take longer to set.

Instrument Needle Valves:

- This valve is used for different gauges and instruments. It helps to isolate and calibrate tools.

High-pressure Needle Valves:

- For working with high-pressure conditions, this valve is used and works in demanding projects.

Needle Valve Advantages

Flexible design

- Normally, a valve has open or closed functions. but the needle valve is different since it has different range options.

- We can set low flow that keeps moving and does not stop.

- so we can set flow movement at different levels according tothe application’s

accuracy

- Its operation is so accurate that it is more effective than other valves. As the needle moves to small degrees, we can control flow in accurate measurements.

- So needle valves are good for applications where certain numbers and measurements are required.

high efficiency:

- It provides high accuracy due to accurate flow control. Since it provides precise flow without wasting fuel, it is a safe and low-cost valve with high efficiency.

safety levels:

- Its operation is safe and accurate. No leakage or damage causes any damage.

Ball Valves vs. Needle Valves

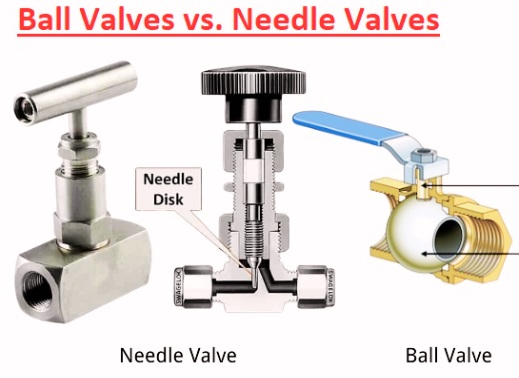

Ball Valves

- A ball valve has a valve-like design; in the middle part of the wall there is a ball with a channel in the middle.

- When the ball rotates at 90 degrees, the channel is exposed to a flow path that makes an open-closed path.

- short throw Actuation of the valve helps to use it for flow control, providing fully open or closed, or quick state changes as needed.

- This design provides airtight sealing.The valve seat automatically gets cleaned through actuation, and its simple design needs less maintenance.

- For high-flow operations, the use of a complete port design shows pressure losses can occur.

- It is a low-cost flow option in different piping processes.

- Fast actuation and low traveling distance make the valve good for some applications but not good where high accurate flow control is needed.

- It is used for different applications like agriculture, construction, and HVAC.

Needle Valves

- needle valve operated with a needle-like plunger for blocking flow in the valve.

- • The threaded, rotating stem adjustment process system provides accurate control for plunger locations.

- It can make minor-level changes in flow rate. This valve is used for manifolds, providing different processing lines for mixing.

- Some needle valves have high resistance for temperature conditions and longer working life for high-pressure conditions.

- It provides smooth metering and a control process due to high-pressure losses in open conditions.

- but needle valves are not good where fast variations are needed for valve conditions.

- Many rotations are needed when moving through the full motion range of the needle-like plungers.

- If valve open or closed handle move freely, make difficult to gauge.

- Pressure losses and accurate control also provide high-restricted flow. Needle valves are good for high-flow processes.

FAQs

What is a needle valve used for?

- needle valve: part of dams, power plants, and water distribution systems to control water pressure and flow rate.

- needle valves used for an automated combustion control system for regulating fuel flow

What is another name for a needle valve?

- needle valve, also called plunger valve, regulating valve, that provides control and regulation of fluid flow and pressure

What is the difference between a needle valve and a check valve?

- • The basic difference between a check valve and a needle valve is design and working features.

- Check valves control reverse flow of fluids in pipes. Needle valves provide accurate regulation of fluid flow.

What are the different types of needle valves?

- It has a needle-shaped threaded plunger, so it is called a needle valve. There are 3 main types of needle valve: standard, motorized, and angle.

- The standard needle valve comes with a handle that manually controls the inline input and output.

read also