The butterfly valve is an important valve type that is used in industries for flow regulation. It comes with a simple design that has a disc-like component that rotates over an axis for flow control

Here, we will cover details of the features of butterfly valves and related factors. So let’s get started.

What Is a Butterfly Valve?

- A butterfly valve is a quarter-turn rotary control system that is used for controlling fluid flow in a pipeline.

- It’s working control through a rotating disc that exists in the flow path.

- This disc is controlled through an external actuator that is connected to the stem.

- When the disc is aligned parallel to the flow, fluid does not flow. When it is at 90 degrees, fluid easily flows.

- Perpendicular rotation of the disc helps to open or seal the valve.

- A butterfly valve is a quarter-turn compared to a ball or plug valve.

- The structure of the valve is simple and can easily connect between two pipe flanges.

- It can be manually operated by using the actuation system configured with the pipeline process control.

- It is accurately used for on-and-off projects, but it has limitations for controlling flow throttling.

- It comes in different designs and types and has features for pressure, temperature, and flow volume.

- Its design helps to manage liquid and gaseous flow.

working of the butterfly valve

- is similar to that of a butterfly valve, like a ball valve, that provides fast on or off.

- • A butterfly valve is used since it has a low cost as compared to other valve types and a low weight, so it is easily connected.

- disc connected in pipe center, rod passes through disc to the actuator at the external side of valve.

- Rotation of the actuator moves the disc at the same axis or 90 degrees to the flow.

- Its disc exists in flow, so it also causes pressure losses in open conditions.

- butterfly valve, also known as a quarter-turn valve.

- During working, the valve is completely open or closed when the disc is rotated for a quarter rotation.

- Basically, a butterfly is a metallic disc connected to a rod.

- If the valve is closed, the disc moves so completely that it stops the flow.

- If the valve is completely open, the disc rotates a quarter turn so that fluid flows without any hindrance.

- • The valve can open slowly for throttle flow.

- Butterfly valves come in different types; each has different pressure features.

- The zero-offset butterfly valve comes with flexible rubber that has a low-pressure rating.

- double offset butterfly valve used in high-pressure conditions

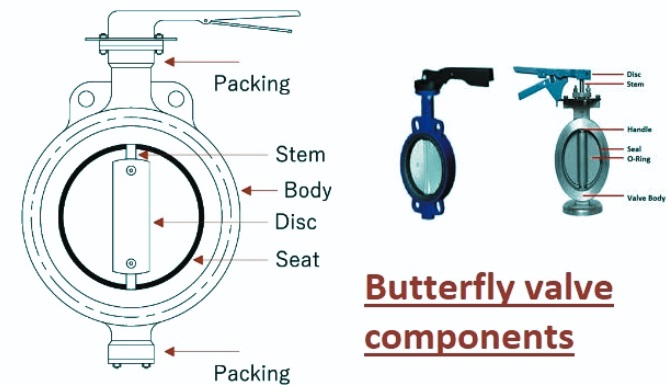

Butterfly valve components

different parts of the butterfly valve, are as

Valve Body

- • The body of the valve fits between two pipes. This valve has two body designs: lug and wafer.

- Wafer design is lower cost than others. It makes a connection with pipes through bolt holes that pass through the valve body.

- This configuration easily connects and is used for controlling reverse flow in any flow system.

- This design is not used for applications where regulation is needed.

- • The lug design butterfly valve is more expensive than the previous valve but has more features.

- lug butterfly valve connected to the pipe with use of a lug hole on the external side of the valve body.

Disc

- It is connected with a valve body that works like a gate to stop or allow fluid movement; it is like the gate of a gate valve.

- • The disc is drilled for getting a stem, or shaft. It comes with different disc designs, directions, and material features for providing good flow, torque, and sealing.

Seat

- Butterfly valve seat made with different polymers and connected to the body strongly.

- The seat moves over the internal valve diameter. When the disk press over the seat, they seal with each other to control flow.

- At the start, the design of the butterfly valve was made with a disk connected to a metallic body that did not have a strong leak-proof assembly.

- The use of polymers in valve design provides leakproof sealing.

Stem

- valve shaft, also called stem, which is the part that makes the connection of the disc with the actuation process and transmits torque

Seals

- Seals exist at different interfaces in the valve for providing strong sealing during working and separating media from the valve’s inner parts for high flexibility and low-cost design features.

Butterfly valve connections

A butterfly valve has two types of connection combinations, that are wafer and lug types. The basic difference between them is that the lug butterfly is used for end-to-line connection and separation.

Wafer-type butterfly valve

- • The wafer butterfly valve comes with 4 holes that connect with the pipeline connection.

- It is strongly fitted between the pipeline and the rubber seal, causing a strong connection between the valve and the flange.

- In the valve, bolts threaded on both ends move through holes in the valve and connect with the pipeline through nuts on the sides.

- • The wafer butterfly valve does not provide end-of-line specifications, and its maintenance provides complete off-system

Lug-type butterfly valve

- • A lug butterfly valve comes with 4 or more threaded holes on every side. Bolts on both sides of the valve pass through connection holes on the pipeline flanges and in the threaded holes on the valve.

- This connection provides a butterfly valve to use for end-of-line operations.

- One side of the pipeline was separated and removed from the valve without disconnecting or shutting down the complete line.

- blind flange used for lug-type butterfly valve for end-of-line operations

Butterfly valve actuation

There are different methods for operating a butterfly valve, like manual, semi-automatic, or automatic.

Electric:

- for this electric actuator used for valve controlling through 4 to 20 mA signal and providing high regulation and time-sensitive applications

Pneumatic:

- It provides high accuracy, and it operates through compressed air for the actuation process.

Hydraulic:

- It is part of applications where high torque is needed for opening and closing valves, like high-pressure and velocity applications.

Manual:

- Manually working butterfly valves use a crank, handwheel, or lever for operation.

- small manual valve fitted with lever.

- For larger sizes, handwheels are used through the gearbox for torque transferring by providing high mechanical features.

- Manual actuation is in conditions where the valve is connected underground without a manhole. For this operation, actuation is performed through the extension spindle and adapter.

Advantages of butterfly valves

Compact design

- Through compact design and low size dimension, the butterfly valve comes with low installation points and has low-cost installation for tools, piping, and tools.

Low Maintenance

- Its design is simple, with fewer moving components and less wear area, which makes it a low-maintenance valve.

high-speed acting

- The vertical rotation of the handle gives complete opening or closing of the valve. larger butterfly valve, gearbox used as an actuation system that minimizes operational torque and makes the working of the valve easy but takes high speed

Low Cost

- Its simple design and need for low material make its manufacturing easier and lower cost than other valve options.

Types of Butterfly Valves

Double Flange Butterfly Valve

- • A double flange butterfly valve comes with 2 flanges on the valve casing that provide high stability and high pressure applications.

- Flanged-type butterfly comes with different types like C504, API609, etc.

- The flanged-style valve comes with zero, single, double, and triple offset features.

- zero and single offset: a commonly used and low-cost option

- AWWA C504 is mentioned on single and zero offset valves; some double and triple offset valves also have these features.

- flanged valve, resilient seated, and high resilient seated valve not replaced seats

- In other words, if the valve was damaged, we needed a completely new valve instead of one part.

Industrial-Style High-Performance Butterfly Valve

- This valve is used for providing high-level flow control and is part of special applications.

- These valves come with a metal-to-metal seat design and provide tight shutdown features for places like power plants, where hazardous materials are used.

- Its seat provides standard resilient seated features.

- Low torque make these valve easy working and increases longer life of the actuator.

- This valve has strong shut-off features, so it is used normally. This valve is made with carbon steel or stainless steel which provides a good shut-off feature.

Waterworks Double Eccentric Butterfly Valve

- double eccentric butterfly valve made with offset shaft and disc, which provides better sealing and lower torque features than other valves.

- This valve provides strong shutoff features for water piping.

- double offset valve is a standard valve in world without the USA and Canada.

- A double offset butterfly valve does not face compression or seat set on a resilient seat.

- It comes with double overlay weld features on the body seat and comes with a non-wetted disc hub.

Triple Offset Butterfly Valves

- This valve comes with 3 offset features: offset between disc and stem, offset between disc and seat, and offset in the sealing area of the seat.

- It has features for rubbing between the seat and seal ring through the flow area that minimize seat and seal wear and increase the working life of the valve.

- • The seat of the valve also comes with a 90-degree cone design due to the offset conical design, which provides smooth working in a complete cycle.

- The triple offset butterfly valve is part of applications where a metallic seat is used and a strong shutoff is needed, but it also opens or closes fast and works in emergency shutoff requirements.

FAQs

What is a butterfly valve used for?

- A butterfly valve is part of a quarter-turn rotational motion valve that is commonly used for pipelines to control flow. Butterfly valves are also used for flow regulation.

When should a butterfly valve be used?

- Butterfly valves are commonly used for water distribution, chemical processing, and low-pressure applications.

- It is good for throttling and completely opening or closing applications that provide effective flow control and regulation of different settings.

What is the main disadvantage of butterfly valves?

- Butterfly valves are not good for high temperature and pressure conditions. It reduces flow capacity for partial opening positions.

- Flow is not smooth if the valve is not completely open.

read also