The basic difference between pneumatics and hydraulics is the medium that is employed for power transmission. Pneumatics uses compressible gases such as pure gas and air. while hydraulics uses a low-incompressible liquid medium like mineral oil, ethylene glycol, synthetic, or water

In this post we will cover detailed features for pneumatics and hydraulics. Find their related factors. So let’s get started. Difference Between Hydraulic and Pneumatic

What Is Pneumatics?

- Pneumatic cylinders are an engineering branch that employs pressurized gas or air for mechanical motion effects.

- Pneumatic systems use different devices, from handhelds to larger machines, and perform different operations.

- pneumatic system operated with compressed air or inert gases that comes with interconnected components like transition lines, gas compressor hoses, gas, and cylinders.

- Through use of these cylinders, airflow is regulated with a solenoid valve, and the cylinders convert energy from compressed gas to mechanical energy.

- Pneumatic applications operating pressure range is 80 to 100 pounds per square inch.

- compressor features for compressing gas based on the compression ratio

What is a hydraulic system?

- hydraulic system working based on fluid power, hydraulic oil, or water used for transferring pressure from one point to another.

- The hydraulic fluids used are mineral oil, water, and synthetic liquid.

- A hydraulic system uses reservoir tanks for fluid storage.

- This system is heavy and uses more space and provides high power.

- Their operating pressure range is 1,000-5,000 psi, and some advanced systems have a pressure range of 10,000 psi or higher.

Pneumatic vs. Hydraulic Systems

Strength

- • The hydraulics system has high strength, and it uses an incompressible liquid medium that has high mass density.

- Hydraulic devices produce high pressure and transmit power for uses.

- Some industrial tools needed 1000 to 5000 pounds per square inch. Some hydraulic operating machines work at 10,000 psi or more.

- Pneumatic system operated with gases with low mass index. Gases easily compress to many hundreds of psi.

- So tools that operate in the range of 80 to 100 psi work with pneumatic systems. This system does not work for heavy equipment.

Hygiene

- Pneumatic causes leakage of air when gases are compressed; they clean metallic particles and oil in the system. Some environmentally friendly manufacturers use pneumatic systems for clean environment and hazard-free manufacturing.

- pneumatic system connected in clean rooms like food laboratories. since these operations do not use hydraulic machines that can cause contamination or any bad materials.

- Hydraulics has a chance of leaking oil or water through damaged hoses or faulty seals.

- It causes contamination in industries and corroded material.

- The hydraulic system needed proper storage tanks and needed to dispose of residues.

Speed

- Pneumatic systems have faster speed operations than hydraulic. since compressed air has a high flow rate.

- It quickly releases energy, providing high-speed actuator movement. Air flows fast in pipes since it has low mass density.

- Pneumatic actuators provide high efficiency since they have high duty cycling and high cycle speed. Fast cylinder motion is important since tools also come in small sizes.

- When compressed air is dumped, the valve and pneumatic cylinders quickly vary direction.

- • The system needed extra disposal. while hydraulic systems are slow since they use water or oil.

- than air, hydraulic, or mineral Oil has high resistance. Oil viscosity affects system working, making it slow.

- Hydraulic fluids provide high force and pressure, but less than air. so take a longer time for operation.

- For avoiding leakage, hydraulic fluids require accurate venting.

Energy

- Both systems use energy for operations. The pneumatic machine needed continuous working of the air compressor.

- Air supply is required regularly since it does not have recycling features. that uses high energy

- • The compression process loses energy through heat production.

- While hydraulic fluid power can be used again after initial starting.

- Through a proper filtration system, we can increase the efficiency of hydraulics.

- It required electric power to operate the pump. but most of the energy used through the pump is wasted.

Medium

- Hydraulic uses a liquid medium, like hydraulic oil or water, for the transmission of incompressible forces.

- Pneumatic system uses inert gases for providing flexible, high-speed actuation and low chances of contamination.

Safety

- High safety features exist for pneumatics. since compressed air leakage does not affect it badly.

- Gasses used in portable tools are not safe.

Complex design

- • The hydraulic system is highly complicated since it has a larger size. This system has fewer moving components and is controlled with a lever or push button.

- Hydraulic also has a complicated design that needed a valve, pump, and hoses.

- This system is connected with external sources and a tank of liquid medium.

- Different hydraulic applications of the manufacturing plant can be controlled through the main power unit.

- • The newly installed hydraulic system provides high speed and power with pressure.

- While pneumatic is simple, components are made with low cost and less complicated materials since the system operates with low pressure.

Maintenance

- • The fluid for the pneumatic system is air, which helps to ease maintenance of the system. but it needed regular maintenance for working effectively.

- The basic maintenance for a pneumatic system is seal checking for avoiding air leakage.

- Regular cleaning and replacement of the filter, regulator, and lubricator are also important.

- Hydraulic has a high corrosion factor.This system required proper monitoring for checking damage of fluid on the pipe.

- Water causes oxidation that is the cause of corrosion.

Features of Pneumatic Cylinders

- There are different features for pneumatic instruments.

- Pneumatic cylinders are high-pressure systems that are based on compressed air for producing force.

- Its cost is less than a hydraulically operated machine, and it also has a good rate of flexibility and provides a high safety level in the system.

- while the pneumatic actuator comes with a longer working life and needs low maintenance, since it causes damage.

- pneumatic cylinders used for vacuum pumps, manufacturing, and assembly lines

- pneumatic system used for keeping constant velocity and less controllable as compared to a hydraulic operating machine

Features of Hydraulic Cylinders

- hydraulic operating machine operated with producing forces through pressurized fluids like glycol, oil, and some flame-resistant liquid.

- In this system fluid moves through producing forces at different points, causing motion.

- Hydraulic cylinders come with high force and provide high accuracy and control.

Hydraulic pump construction

- The use of accurate materials for hydraulic pump production is important, as is pump design such that it can handle high inner pressure and provide a longer working life.

- Its parts are made with metals that have high tensile strength, like steel and cast iron, which avoids damage in case of high load.

- Thickness is the main factor for design, mostly for pumps used for heavy-duty applications.

- The main factors, like comprising gears, vanes, screws, and housing, are accurate machines for tolerances and sealed to control hydraulic fluid leakage.

- Each part faces a different testing process for managing structural quality and leak-proof design.

- Hydraulic pumps come in different sizes based on pump type, required performance, and applications based on load.

- Some advanced materials, like elastomers and polymers, are used for hydraulic fluids since they have high resistance to wear and maintain seals at different temperatures and pressures.

Applications of pneumatic system

- Conveyor systems

- Pressure sensors

- Vacuum pumps

- Air compressors

- HVAC control systems

- Precision drills and nail guns

- Assembly and manufacturing lines

applications for hydraulic systems

The applications of the hydraulic system are as

- Machine tools

- Car braking systems

- Wind turbines

- Excavators and cranes

- Theme park rides

- Lifts

- Mechanical chairs

Hydraulics vs. Pneumatics Actuator

- hydraulic actuator operated with fluid and produces high forces for handling high pressure.

- This system produces 25 times higher than a pneumatic cylinder.

- Hydraulic oil is an incompressible medium; the actuator holds torque without regular fluid pressure or power supply.

- • A leaking hydraulic actuator causes contamination and also affects internal and external components.

- This system causes noises, also for noise reduction tools.

- Pneumatic actuators require low power. It is highly constant and reliable. It used compressed air, so there were no certain requirements for air motors.

- This actuator causes fluctuation and loss of pressure since air is compressed.

- The pneumatic actuator and air compressor need to exist closely so the system can operate continuously.

- For low or high temperature, pneumatics are more reliable tools than hydraulics.

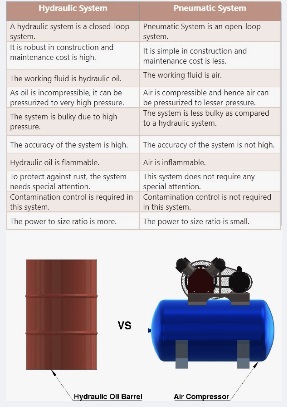

Difference between Hydraulic system and Pneumatic system

| Hydraulic System | Pneumatic System |

| hydraulic system is basically a closed-loop system | an open-loop system. |

| complex design needed, coslty maintenance | simple construction and maintenance costs low |

| fluid is hydraulic oil. | air used as fluid |

| As oil has an incompressible nature, so pressurized to high pressure. | Air is compressible and so air can be pressurized to a lower pressure. |

| highweight since has high pressure. | low weight than a hydraulic system. |

| high accuracy | The accuracy is low |

| Hydraulic oil is flammable. | Air is inflammable. |

| it needed protectiion from rust. | no special features needed |

| Contamination control needed | Contamination control not needed |

| The power-to-size ratio is higher. | The power-to-size ratio is small. |

faqs

Is a hydraulic hose like a pneumatic hose?

- No, both are different. Hydraulic hoses are used for handling pressure conditions normally related to fluid power systems. while pneumatic hoses are used for lower-pressure air or gas systems.

Which is better, pneumatic or hydraulic?

- Pneumatics is good where hygiene and cleanliness are needed, like in medical conditions, and hydraulics has high force and power required for industries and construction.

What are the advantages of hydraulics?

Advantages of hydraulic systems are:

- It has self-cooling and lubrication features.

- small size and low-weight design.

- Used for heavy loads and comes with different speed control features.

- It has a high-speed response.

What are examples of pneumatic systems?

Common examples of pneumatic systems are

- air tools like air ratchets and impact wrenches

- pneumatic actuators such as cylinders for linear or rotary motions of machines.

- automated machines, used for packaging lines for labeling and sorting

- HVAC control system, used for controlling airflow and temperature control

What are the advantages of pneumatic systems over hydraulic systems?

- Air fluid is free of cost, so this system is low-cost as compared to other fluid types.

- Pneumatic systems are safe operations in flammable conditions since compressed air does not cause fire damage like flammable liquids.

- The pneumatic system is clean since it does not use oil.

.