Broaching is a process that operates with toothed devices for accurately removing materials. The broaching is performed in two services, rotary and linear, that use different machines and finishes. Production broaching is normally used for precise and bulk production. In this post, we will cover details for the broaching process features and related parameters. So let’s get started.

What is broaching?

- Broaching is a machining method that correctly removes materials with the use of toothed instruments.

- This method uses devices that are configured with teeth of different ranges that can remove different quantities of material for every pass on the working component.

- The broaching process involves different toothed tools moving and working piece is static.

- In some conditions, there is relative rotational motion between the tool and the working component.

- Broaching is performed internally with the center of a working component or over the surface.

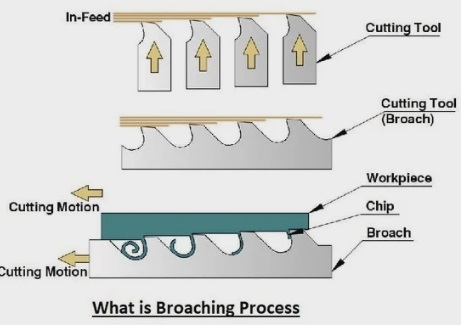

What is the broaching process?

- The broaching process is based on the surface or internal broaching employed. Surface breaking is an easy and simple process since it involves the action of surfaces on each other.

- Such as broaching tools, one is in a static and working component moving in the reverse direction, and the other option is the working component is static, and the broach is moving over it.

- Internal broaching is a difficult process. For internal broaching, the working component is set at a position through the working holder that works as the mount of the broaching machine.

- After that, with the use of the elevator on the machine, the broach lowered over working components.

- After that machine puller holds the broach pilot, and if the elevator releases, the follower puller pulls the broach completely into the component.

- The last working component was removed, and the broach was set with the elevator.

Components of Broaching

Broach:

- The main component of the broaching process is the broach, which is a long, thin device that comes with different teeth. It is made for cutting any shape of working component.

Workpiece:

- The materials on which broaching is performed are called the workpiece. It is made with the use of different metals such as steel, brass, or aluminum.

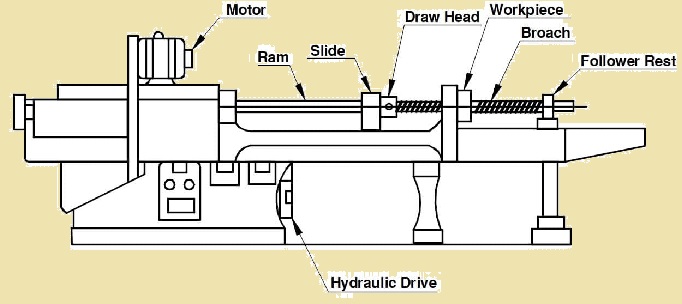

Broaching Machine:

- The machines used for this process are called broaches. The broaching machine holds the working component and helps the broach to move through materials.

Fixture:

- The device that holds the working piece in position at the time of the broaching process is called a fixture. The fixture provides stable and accurate results at the time of the cutting process.

Cutting Fluid:

- For minimizing friction, heat dissipation, and providing high efficiency of the process, cutting fluid is used at the time of broaching.

How Is Broaching Process Performed?

Set up

- First of all, application of the broaching process setup is arranged. The working piece is fixed at the position with the use of a fixture on the broaching machine. Accurate configuration is used to provide accuracy for the final assembly.

Brooch Selection

- The selection of an accurate broach is important. That comes in different designs and shapes, so the selection of a proper broach is based on features and working piece materials.

Broaching Operation

- The broach is accurately applied to the working piece, cutting materials with each movement. The process is finished in one stroke, and it is an effective way. Linear or rotary cutting is involved, based on the broaching machine and uses

Testing

- In the last step, when broaching is completed, it faces different inspection and testing methods for getting the required results and features.

How Is the Broaching Process Performed?

Set up

- First of all, application of the broaching process setup is arranged. The working piece is fixed at the position with the use of a fixture on the broaching machine. Accurate configuration is used to provide accuracy for the final assembly.

Brooch Selection

- The selection of an accurate broach is important. That comes in different designs and shapes, so the selection of a proper broach is based on features and working piece materials.

Broaching Operation

- The broach is accurately applied to the working piece, cutting materials with each movement. The process is finished in one stroke, and it is an effective way. Linear or rotary cutting is involved, based on the broaching machine and uses

Testing

- In the last step, when broaching is completed, it faces different inspection and testing methods for getting the required results and features.

Rotary Broaching Machine

- Rotary broaching is called wobble broaching, which is different from other broaching machines. It is an accurate method for making an inner polygonal design.

- For rotary broaching, the cutting device is put at a one-degree angle to the centerline of the working component, resulting in broach cutting with a scalloping effect.

- Rotary broaching is performed with a lathe or milling with the use of a horizontal or vertical spindle machine where the spindle moves freely. The design is made with the use of rotary broaching, such as hexagons, serrations, keyways, splines, numbers, and letters.

CNC Broaching

- The computer numerical control machines are also used for the broaching process. This machine has features to do rotary and linear broaching in one operation. Broaching service providers have made a certain type of tools, tool parts, and holders that can be easily configured with a CNC system.

- CNC broaching comes with indexable insert devices and custom tool holders. That holders handle different inserts, providing different broaching types, such as rotary or wobble broaching, keyways, splines, serrations, etc.

Uses of Broaching

There are a plethora of uses for brooches. In fact, you have likely seen types of broaching in hand tools, appliances, plumbing, automotive design, farming equipment, and a variety of other military and industrial applications.

However, the primary use of broaching is in the production of high-volume parts that require accurate, repetitive, and complex cuts. While the broaching process can be used for a variety of applications, the best materials to use are those with a hardness rating of between 26 and 28 Rockwell C.

However, many production companies have seen success by using materials up to a hardness rating of 32 Rockwell C.

Different types of broaching

Broach

- The broach is a cutting instrument that comes with different teeth, and each is larger than the previous one. That design provides a broach for making simple and complex cuts fast and with accuracy. In the broaching process, each broach pass removes a shallow material layer over the working component length.

Linear Broaching

- The linear broaching is a commonly used method. In this technique, tools move in a single line over the surface of the working component, cutting processing.

Pull Broaching

- In this method, broaching is performed through the static working component. That method uses long broaches that have a certain head, and tension produced at the time of the pulling process provides a good broach. Pull broaching is used for inner broaching and also for surface broaching.

- This broaching technique comes with different teeth that provide good cutting operations.

- Pull broaching is done in vertically or horizontally on the working component. It is used for making a flat surface on automobile cylinder blocks and heads.

Push Broaching

- The push broaching tool is a small size for handling compressive forces applied at the end of the broaching process.

- It normally comes with fewer teeth that can bend or break under pressure. Pushing broaching is good for making shorter cuts and for making small components.

- Push broaching tools are used for surface broaching, and these applications are called surface broaching tools.

Features of Broaching

- It comes with a larger manufacturing rate compared to planning, boring, or milling techniques.

- It makes high-dimensional and high-accuracy output products.

- Roughing and finishing in one stroke are provided with the same cutter.

- It uses a single motion of cutting, which provides simple design and control.

- It is a good and low-cost option for bulk production.

- It does not need a special type of expertise to perform.

- It has a short time cycle with high accuracy with the use of fewer skills to perform broaching operations.

- Broaching is applied for inner or outer surface finishing.

Limitations of Broaching

-

- It is used just for the surface and through-hole process.

- It applies for light cuts and does not have a high cutting speed.

- It has a high bad effect on product quality if any damage in the broach.

- The designing and production of brooches is a high-cost and difficult process.

- It is only a low-cost option for bulk volume and a high-cost option for short work.

- It is a high-cost device and not used for removing larger stock.

- It is not operated for larger-sized components.

FAQs

Why is broaching used?

- Broaching is used for providing accurate machining in different shapes. Commonly machined surfaces are circular and non-circular holes, keyways, splines, and flat surfaces. The normal working workingcomponent is small- to medium-sized casting, forging, and screw machine components.

What is the broaching engineering process?

- Broaching is a machining process that comes with material removal through the use of a broach tool. The broach is a multi-tooth cutting tool that increases in size and helps to cut in different parts of the working piece.

What is broach metal?

- Broaching is a process that is performed with a toothed tool for removing material. Broaching has two main types: linear and rotary. Linear broaching is a common type where the broach is moved linearly over the working component surface to make a cut.

Are broaching and milling the same?

- No, they are different; the basic difference is the speed at which materials are removed. Normally, cutting speed for broaching is about 2.5 and 80m for one minute and 75–450 m min−1 for conventional processes.