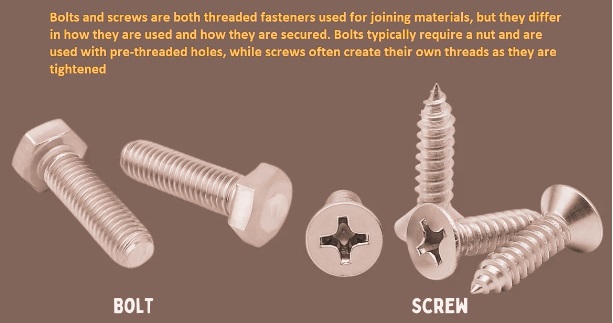

Bolts come with a partially unthreaded shank and use a nut for fastening, and screws are threaded completely over the shaft and driven on different materials. Bolts are employed with pre-drilled holes and nuts, tightened with turning nuts and screws, and make holes since they are driven in and tightened with turning heads. In this post we will cover details for finding differences between a bolt and a screw.

What is a Bolt?

- A bolt is an externally threaded fastener that is made to insert into holes of assembled components. Normally, bolts come with a smooth circular cross-sectional area.

- Bolts are used with nuts and connect with the use of spanners and wrenches for loosening and tightening.

- Components that are connected with bolts come with high strength and longer life. As a result, bolts are a reliable fastener. Bolts do not come with a tapered shank but have a cylinder shank with a smooth cross-sectional area.

- Bolts exert compression on various components to which they attach. The bolts come in different sizes, from small to larger sizes.

- Bolts are normally used for making a bolted joint with the use of a nut for application force, and the shank is used as a dowel. As a result, the joint is compatible with sideways forces.

- As a result, different bolts come with unthreaded shanks that make them effective for dowels.

- Bolts have different types that are anchor bolts, elevator bolts, arbor bolts, change bolts, J bolts, lag bolts, and U bolts.

- Bolts are also made with different materials such as steel, stainless steel, bronze, brass, and nylon.

What Is A Screw?

- • A screw is also an externally threaded fastener that has a feature to put into holes of assembled components.

- Screw not needed for nuts for connections. The threads on screws are of helical design and come with a larger pitch.

- • The screw does not come with a tapered shank or can be and needs a screwdriver for loosening and tightening.

- The components connected with screws come with lower strength than bolts.

- Screw comes in different sizes: small or medium level

- • The screw is connected in threaded holes. Bolts are not used since they are secured by tightening on holes with a screwdriver or screwdriver bits that fit into the drive recess.

- Screws are normally smaller in size than the width of the materials they are screwed onto.

- Screws also come in different types, such as chipboard screws, particleboard screws, drive screws, hammer drive screws, eye screws, wood screws, and sheet metal screws.

Difference Between Bolt and Screw

Bolt

- The bolt is an externally threaded fastener that inserts through holes in assembled components and is tightened or loosened with nut torquing.

- Bolts comes with a smooth cross-section, and it is always used with nuts.

- Its threads are spiral in design and do not have a tapered shank.

- It needed wrenches and spanners for loosening and tightening.

- The components or parts connected with bolts provide high strength as compared to screws. That makes it reliable.

- It is used for the application of compression on connected parts. The parts connected with bolts needed to have holes for bolt insertion.

- Bolts come in different sizes, from small to large.

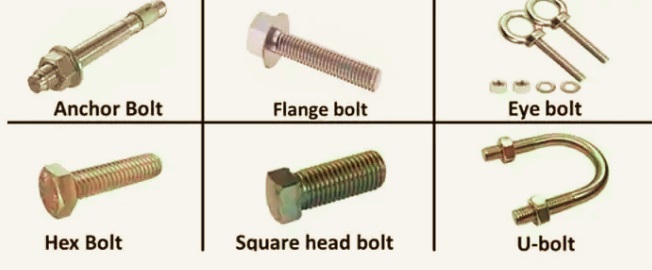

- The main types of bolts are U-bolts, J-bolts, eye bolts, carriage bolts, elevator bolts, hexagon bolts/tap bolts, lag bolts, flange bolts, hanger bolts, machine bolts, plow bolts, stud bolts, timber bolts, T-head bolts, shoulder bolts, square head bolts, toggle bolts, etc.

Screw

- • A screw is also an externally threaded fastener that has features for insertion in holes of components or parts, without any inner thread or making its own thread.

- It is a non-uniform cross-section component and does not use nuts for connection.

- Threads on the screw are of helical design and come with a taper.

- Screw uses a screwdriver for loosening or tightening purposes.

- The components connected with joints with screws come with lower strength than bolts.

- It is low in reliability and does not apply compression to components connected.

- Based on requirements, holes were needed in parts that connected with screws. In some conditions it directly screwed on the connected part.

- Screw size is small or medium and does not come in larger sizes.

- The main types of screw are sheet metal screw, mating screw, machine screw, self-drilling SMS, socket screw, eye lag, thread-cutting machine screw, set screw, etc.

Types of Bolts

Hex Bolts:

- These bolts come with a hexagonal head and are used in machines and for other purposes. They provide a strong grip and easy torque transmission.

Flange Bolts:

- Through the flange, these bolt types easily transmit pressure and minimize the chance of loosening. They are part of mechanical operations and vehicles.

Square Head Bolts:

- These bolts have a square head and provide high torque transmission and are used for restoration projects and older constructions.

U-Bolts

- It is a U-letter-like design, and these bolts are used for pipe and round object connections.

J-Bolts

- It is J-shaped, and these bolts are part of the anchors in the concrete design.

Bolt Materials

Carbon Steel:

- It is a general-purpose material and commonly used.

Stainless Steel

- This material has been used since it has good corrosion resistance and is best used for wet conditions.

Alloy Steel

- It is high strength and part of different demanding applications.

Brass

- It has high resistance to corrosion and electrical conductivity and is used in electrical and decorative applications.

Aluminum

- It is a low-weight and high-corrosion-resistance part of aviation and lightweight designs.

Different Types of Screws

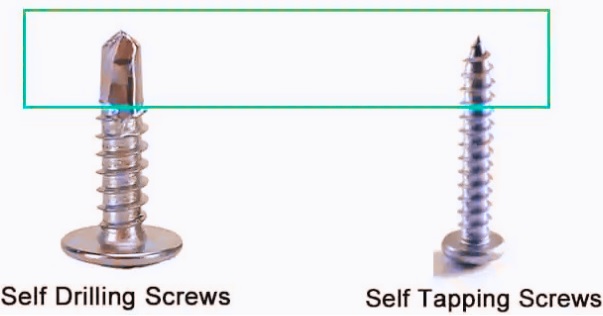

Self-Drilling Screws

- These screws come with a drill bit end that helps drill and tap to make a hole in metal and other materials with a hard design. They are part of metal roofing and sheet metal working.

Self-Tapping Screws

- These screws make threads in materials such as metal, wood, and plastic. It is used where a strong hold is needed, like in metallic frame working and electrical design.

Drywall Screws

- These screws are used for fastening drywall to metal studs or wood. They come with a bugle head to avoid tearing drywall.

Chipboard Screws

- This component is used for the fastening of particleboard and composite materials. They come with deep threads for providing a strong grip.

Wood Screws

- This screw is used for the connection of wood components. They come with sharp points and deep threads for the strong wood hole.

Machine Screws

- These screws are used for fastening metal components with each other through using pre-tapped holes. They exist in different head shapes, like hex, round, and flat.

Tapping vs. Non-Tapping Screws

- Tapping screws, also called self-tapping screws, come with threads that cut into materials to make their own thread.

- It comes with a painted tip and is driven directly into materials such as metal, plastic, and wood without the use of a pre-drilled hole.

Tapping Screws

- These screws come with sharp, cutting thread designs and pointed tips.

- They make their own thread since they are driven in different materials.

- For installation, they do not need pre-drilled holes or pilot holes.

- They are used for sheet metal working, plastic assembly, and also woodworking applications.

- They are high-speed connection screws and do not use separate tapping operations.

Read also:Mig Vs Tig Welding: Basic Differences

Non-Tapping Screws

- They are standard threads and come with different tip designs.

- It needed pre-existing threads or pre-tapped holes for proper working. For installation they use tapped and pre-drilled holes.

- It’s used in machines, furniture assembly, and general assembly.

- Its main feature is accurate fitting with prepared holes.

Self-Drilling Screws vs. Self-Tapping Screws

Self-Drilling Screws

- They come with a drill bit end that helps to drill and tap your own hole easily.

- It is good to use for metal and materials that are hard and structured.

- It is easy to install since it does not need a pre-drilled hole.

- It is used for metal roofing, steel framing, etc.

Self-Tapping Screws

- It comes with sharp threads without a drill bit end. It needed pilot holes pre-drilled.

- It is used for different materials such as metal, plastic, and wood.

- Common uses are in metalworking and woodworking.

Conclusion

The use of an accurate bolt or screw is based on applications, materials used, and level of performance. Bolts and screws look the same but are not; they are different in threading, installation, and applications.

FAQs

Read more: What Is Locknut? Features, Types, and Application

What is the basic difference between a bolt and a screw?

- • A bolt is used with a nut, and it is tightened with the torque of the nut. The screw is made to use with preformed or threaded holes, and it also has features of its own threaded hole. The screw has a design for tightening with torquing the head.

Can a screw be used as a bolt?

- Machine screws are machine bolts. Machine bolts fasten by mating with nuts or threaded holes that are not used as bolts.

What’s the difference between a bolt and a set screw?

- Bolt and set screw The difference is that there is a thread on the complete length of the screw, and the bolt is partly threaded. Up to 1/2″ dia., more than 1/2″ dia.

What size are the screws and bolts?

| Metric bolt thread sizes | Major diameter (mm) | Pitch diameter (mm) |

|---|---|---|

| M4.5 | 4.5 | 4.013 |

| M5 | 5.0 | 4.480 |

| M6 | 6.0 | 5.350 |

| M7 | 7.0 | 6.350 |

What is the difference between a nut, bolt, and screw?

- The head of the bolt is hexagonal, and the shank comes with an external thread. The screw has a small head and comes with a flat head, and the cross head and rod come with an external thread.

Why use a bolt instead of a screw?

- Bolts have features for higher strength than screws. That is partially due to the existence of a washer, which spreads out the load over a larger area. Bolts provide high strength and work well for heavy-duty and load-bearing applications.