Hydraulic elevators are a commonly used lift type, as are traction lifts, since they are a low-cost and reliable lift type. This lift operates with the use of hydraulic fluid and a piston system for moving the lift car up and down smoothly. In this post we will cover details for hydraulic elevator features and working with different types.

What Are Hydraulic Lifts?

- The hydraulic lift is a high-power machine that operates with Pascal’s law, which defines that pressure applied on a fluid is transmitted uniformly in different directions.

- Through using this principle, hydraulic lifts have features to lift high-weight loads with high accuracy.

- It is also used in the manufacturing industry and vehicle construction.

- The hydraulic lift is a system that is used for elevating objects with the use of force produced through liquid pressure in a cylinder, helping the piston to move in an upward direction.

- Incompressible oil is added into the cylinders, and the piston is elevated.

- When the valve opens, it helps oil to release, and the piston lowers due to gravity pull.

- As hydraulic lifts operate with Pascal’s law, which defines that changes in pressure applied to incompressible fluid in a closed space are applied to the complete liquid in all directions

- Hydraulic systems have benefits for providing accurate control in high-force uses and low-cost options for energy applications.

Hydraulic lifts working

- Hydraulic lifts are the main component of engineering systems that work through Pascal’s law for lifting heavy objects easily.

- Pascal’s law states that pressure on a fluid is uniformly distributed in different directions.

- Hydraulic lifts use this working principle to make strong forces to lift and move larger objects.

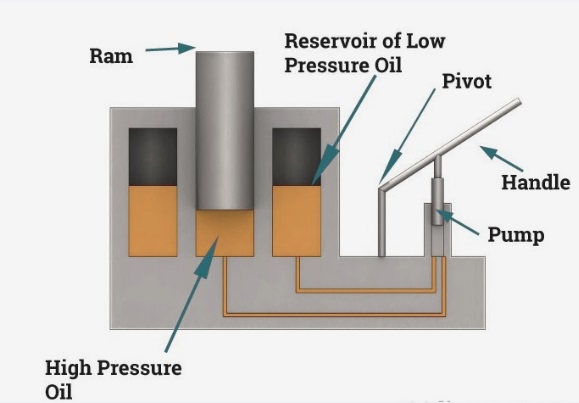

- The main parts of a hydraulic lift are the pump, fluid reservoir, and control valves.

- The pump applies pressure to fluid that exits in the reservoir. After activation, the pump transmits fluid into the cylinder; as a result, the piston rises and lifts the load.

- Control valves are important for proper control of lift motion. It regulates fluid flow in and out of cylinders to provide an accurate lifting process.

- the adjusting of these valves, we can control light direction and speed

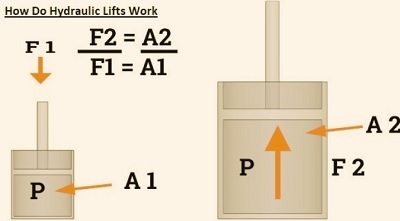

- The main working of hydraulic lifts is the force multiplication process; a minor force applied to a small piston is increased when transmitted to a larger piston, providing a strong force.

- This helps hydraulic lifts to lift high-weight objects that we cannot lift by hand.

How Do Hydraulic Lifts Work?

- The hydraulic lift works through hydraulic principles, with use of Pascal’s law for increased force strength. For hydraulic systems, force is applied at one point to incompressible hydraulic fluid that transfers through piping to a 2nd location, resulting in effective motion.

- The working is based on two interlocked pistons that are master and slave cylinders that are connected through reinforced hydraulic lines that have fluid master and slave cylinders—connected via strong, reinforced hydraulic lines filled with oil or hydraulic fluid.

Here you can see two piston connections through a pipe.