Linear actuators are important for different industry applications and are used as the main component for different processes. It is a mechanical device that is used for the conversion of energy into controlled motion or force to operate a machine. Linear actuators are important for the manufacturing industry, automation, and logistics.

In this post we will cover details for linear actuators and related factors. Let’s get started.

What is a linear actuator?

- Linear actuator used for the conversion of rotary motion into linear motion helps to lift, slide, and tilt different tools and objects.

- It provides effective and required low motion for control motions. Electric linear actuators use a DC or AC motor coupled with a gear assembly and cause a screw system to extend over a basic rod shaft.

- The motor sizes use different actuators with a voltage range of of12V DC to 48V DC.

- The main features for linear actuators are static and dynamic load features. Dynamic load features show the force handled during working, and static load capacity shows the forces that support static conditions and maintain the load.

- Actuators are important to use for performing automated operations like car seat adjustment, automatic door opening, and also controlling the computer’s disk driving system.

- Linear actuators work according to inclined plane features, and the lead screw uses low rotational force for moving the ramp up and down.

Linear actuator working

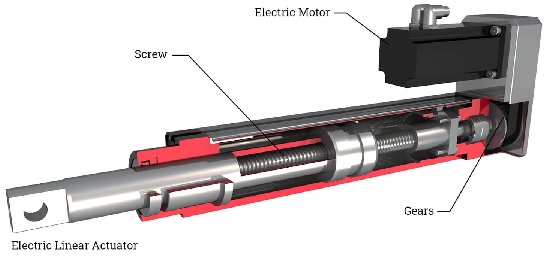

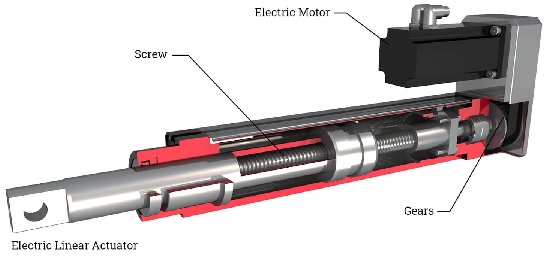

- Due to the rotation of the motor lead screw drives, the nut moves over the screw thread and converts rotational motion into linear motion.

- Linear actuators are used for different applications like robotics, automotive systems, medical devices, and the aviation industry and for applications where accurate linear motion is needed.

- It also has different types, like hydraulic, electric, pneumatic, and mechanical, that have their own features.

Linear Actuator Parts

Power Source

- It is an AC or DC motor that delivers power for actuating the actuator. Electricity is a common power supply; there are some that use air or fluid for energy delivery.

Power Converter

- It is a device that converts the power of a source to an actuator that is in a certain direction from the controller. The basic types of power converters are proportional valves and electrical inverters.

Actuator

- An actuator is a mechanical device that is used for converting input energy into controlled, repeated linear motion.

- According to design, electric linear actuators and pneumatic cylinder actuators provide working for automation, industrial machines, and medical devices.

- Different factors like construction material, ingress protection rating, and actuator define their use for certain conditions.

Mechanical Load

- The load is operated with an actuator according to a mathematical expression or load capacity chart. Loads are measured vertically and horizontally with x and y axis motion. The actuator operated with two loads, static and dynamic.

- Static load is force when the actuator is not in motion, and dynamic force occurs when the actuator is moving. Each load produces a certain capacity range.

Controller

- The controller is the main part of the latest actuator system that provides logic processing cues, also motion control, and its cover is user interfacing.

- For setting the motion profile, a position controller was used, and some of the latest control features collaborated with PLC interfaces.

- The controller is also compatible with the automation process and remote monitoring and provides real-time updates and proper maintenance.

Phase Index™ Sensor

- The main feature of actuator sensor control is the phase index sensor. That is a digital high-speed, high-resolution, and non-connection positioning sensor for electromechanical actuators.

- It provides resistance for vibrations, moisture shock, and dust particles. It does not need a backup system since it has self-calibrating sensor features if no power occurs. The actuator will restore power instantly.

- Power index sensor control defines position from the phase between two cyclin signals of different periods.

- The main advantage of sensors is high accuracy for different conditions, and they also operate well in different conditions.

Types of linear actuators

Electric linear actuator

- This type of actuator uses an electric motor for producing linear motion. It also has some subtypes, like screw-driven, belt-driven, or gear-driven actuators.

- Electric linear actuators also come with some more features, like accuracy, flexible nature, and simple controlling process.

Hydraulic actuator

- Hydraulic actuators operated with use of pressure-based fluid for generating linear motion. It is also used for heavy-duty applications that need high forces, like industrial machines, construction devices, and aviation systems.

Pneumatic actuator

- Pneumatic actuators operated with compressed air for producing linear motion. It is also used for applications that need fast and repeated motion, like robotics, automation systems, and assembly lines.

Mechanical linear actuator

- Mechanical linear actuators operate with systems like levers and cams and convert rotary motion into linear motion. It is a simple design component and used for low-force applications that do not need precision.

- Mechanical actuators are good for transforming rotary motion into linear motion.

Piezoelectric actuator

- The piezoelectric effect is the main feature of materials where voltage applied to materials causes expansion. High voltage causes a small expansion. As a result, piezoelectric actuators get high position resolution with short-range motion.

- Piezoelectric materials show hysteresis that affects controlling expansion for repeated ways.

Coiled Actuators

- The coiled actuator uses magnets to produce a magnetic field and induces current for moving the coil which causes motion of the connected shaft. Force of motion is defined by motion speed, turns in coil, magnetic flux, and current that increases for high force.

Electro-Mechanical Actuators

- Electromechanical actuators are digital modules that help program force and motion profiles through personal computers. The application of a mechanical actuator is like an electric actuator since this actuator induces rotary motion with the use of electrical sources in motors.

- It comes in different motor types, like DC brushless, stepper, or servo. These actuators are used in different applications and operations.

Load Capacity of Linear Actuator

- The load capacity of a linear actuator is defined with features to hold and move the load. Loading is defined as forces that compress the linear actuator and also forces that pull away through the actuator.

- There is some load fatigue defined by ISO standard 14728-1:2017 for linear actuators.

- The two measurements for linear actuators load capacity are static and dynamic. If the linear actuator is for dynamic position, it is a motion state. For a linear actuator in a static position, it holds the load in a defined position.

- Static load capacity is defined as the safe holding capacity of the actuator without any damage.

Linear Actuators Working Life

- The normal linear actuator has a working life of about 20 million cycles. Motor fatigue is defined through users applications.

- For increasing working life, use a motor that has a safety factor of 2 or higher. Then make sure that system is mechanically fit.

- that is performed with reducing side loading, impact loads, and unbalanced loads.

- Each system has features to provide proper heat dissipation.

Selection Factor for Linear Actuator

There are different types of linear actuators; each has its own features that are used for certain applications. For getting a certain actuator, there are some factors that must be considered before using any linear actuator.

Evaluation

- Find where we can use an actuator; it is important to find details for the motion required. Such as the motion for opening and closing a door or valve, which is not the same as that required for actuating a machine process.

- Actuators are made to provide linear motion or rotary motion. It is good for the evaluation of the motion required and the integration process for selection of an accurate actuator.

Power Source

- Electrical actuators comes with refined feature and optimzed for different projects and common used acctuator

- But not all applications use electrical parameters. It is good to use pneumatic or hydraulic actuators according to the power supply.

Accuracy

- The actuator that is designed to operate for external conditions that need high accuracy will not work for heavy-duty operations like in industries. The features of the actuator are based on size and working environment.

- Small and sensitive operations use high-accuracy motion actuators, and stacking pallets does not need this level of accuracy.

Force

- The main function of an actuator is to apply force for performing work like lifting, moving, activating, and sliding objects. The working of an actuator is based on the force required for the motion of the load, and it is called the load capacity. Each manufacturer provides a certain load capacity for the product, and these details must be checked for proper actuator working.

Movement

- Each actuator has a certain motor and stroke length. Stroke length is defined by the length of the lead screw, and before getting a good actuator, check if the motion is needed for certain tasks for the actuator to fulfill the required distance.

Speed

- Speed is also a factor that helps to choose the proper actuator, but it is based on the weight of the load. Such as if high forces needed the actuator to move at slow speed. The speed unit is distance per second; measuring the proper duty cycle is good for method for getting this data for the selection of an accurate actuator with speed and working performance.

Actuators: Advantages and Disadvantages

|

|

Advantages |

|

| Mechanical |

It is low-cost and has repeated features without needing any power supply, and it is self-contained with the same features for extending or retracting. |

It operated manually and did not have an automated process.

|

| Electro-mechanical |

It is low cost and repeated, with automated operations, and self-contained.

It comes with DC motors and position feedback features with extending or retracting. |

Its larger number of parts causes damage or wear.

|

| Linear motor |

It has a simple design and low moving components with high speed possible and is self-contained. With extending or retracting. |

It applies for low- to mid-level forces, not for high-level forces.

|

| Piezoelectric |

It has small motions for high speed and uses low power. |

It needed amplification for longer travelling and needed a high voltage of about 24 or higher. It is low-cost, and its fragile nature works well for compression, not for tension.

|

TCP: Twisted and

coiled polymer |

Low weight and less expensive |

It has low efficiency and a high temperature range needed for working.

|

| Hydraulic |

It provides high forces and high power-to-size ratio |

It causes a leak and needs position feedback for repeatability, and also needs an external hydraulic pump

|

| Pneumatic |

It is strong and lightweight |

It needed position control

|

| Wax motor |

Smooth operation |

it not work as other methods

|

| Segmented spindle |

It is compact and provides different motion features than the actuator length |

it needed both linear and rotary motion.

|

| Moving coil |

It provides controllable features for force, position, and speed and has features for high speeds and accurate position |

It needed position feedback to be repeatable.

|

Conclusion:

- The main use of linear actuators is to transform rotational motion into linear motion that helps to lift, slide, and drop other materials. All linear actuators work the same way; there are different methods of motion we can get. Linear actuators have different possible applications in industries and other conditions.