A simple machine is a mechanical device that operates with an input force to provide larger output force. Input force does not operate the output load, and a simple machine makes work easy through the use of different methods, it increases output. In this post, we will cover details about simple machines and their practical uses.

What are simple machines?

- A simple machine is a mechanical device that helps to change force magnitude and direction. For simple machines, single forces applied against the load force and input force apply work on the load.

- The machine increases output forces while reducing load displacement.

- A mechanical feature for a simple machine is the ratio of the output force with the input force. The main types of simple machines are lever, wheel, and axle; pulleys are also used.

- The work done is a multiple of force and displacement, and the distance over which force is applied increases to make our work easy.

- The changes in the force’s direction and velocity through which it is applied can also be used.

- We can make work easy through increasing distance for the applied force and variation of force and velocity.

- The normally used 6 types of simple machines are as

- Lever

- Wheel and axle

- Pulley

- Inclined plane

- Wedge

- Screw

Simple Machines Working

The working of a simple machine is based on some factors such as

- It varies force direction and increases force magnitude.

- A machine transmits force from one point to another.

- It also increases speed or force distance.

Work is defined as energy transferred as a result of a force moving an object through a distance. That is explained as

W = F × d × cos(θ)

Where:

-

- W is the work

- F is force acting

- d is the distance covered through the body where force is applied.

- θ is the angle between the force vector and the distance vector.

Most common simple machines

Pulley

- The pulley is a wheel that comes with a flexible rope or cable chain on the rim. Pulleys are used alone or in combination to transmit energy and motion. Pulleys that come with grooved rims are called sheaves.

- In belt drive, pulleys are configured with shafts at axes, and power is transmitted between shafts through the use of endless belts moving over pulleys.

- For getting high features, we can use one or more pulleys; normally this combination is used for weightlifting features.

- The shaft over which the pulley moves can be set and fixed on frames or blocks, and the collective use of pulleys, blocks, ropes, and other materials is called block and tackle.

Screw

- The screw is an inclined plane that wraps over a cylinder. When we turn a screw, we apply rotational force that is converted into force that presses the screw into the material.

- The closed space thread of the screw is a long, shallow inclined plane that provides mechanical working.

- The mechanical strength of a screw is based on the circumference of the screw and the pitch.

- The small pitch provides high strength since it takes low forces for the connection of the screw in the material with high revolutions.

- The main examples of screws are wood screws to fasten and connect nuts.

Lever

- The longer beam that connected on the support point, which is called a fulcrum, is a lever. If we set the fulcrum close to heavy bodies and apply force from a distance, the lever is used for lifting loads.

- The object moved with the lever is called the load, and the force applied on the lever is called the effort or input force.

- Crowbars are lever types that help workers and carpenters easily extract nails from wood.

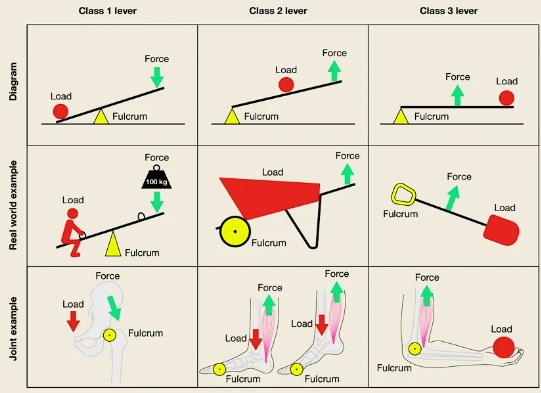

Types of Levers

- We can see levers around at different places, like hammers, tongs, knives, wrenches, and axes; all are levers. All are levers but have different working features. The common types of lever are as

Class-1 Levers

- For class one lever force, we apply it on the reverse side of the fulcrum to the force generated. The basic example of a class 1 lever is a seesaw.

Class-2 Levers

- The class 2 lever is configured in a different direction and has a fulcrum at one end. We apply force at the other end, and force is generated at the center point. Garlic presses and wheelbarrows are examples of this lever.

Class-3 Levers

- The class 3 lever, like class 2, comes with a fulcrum at one point, but two forces switch over. We can apply force in the center, and force is generated at the reverse end.

- Class 3 levers are contrary to other machines that reduce applied force and provide high control.

- Tweezers and tongs are basic examples of class 3 levers.

Wedge

- The body that tapers with a thin edge and makes separated material. It is used for splitting materials like an ax and for holding things like a doorstep.

- A wedge used for designing modern cars and jets to cut through air by directing the pointed wedge to the front.

Wheel & Axle

- It comes with a circular wheel connected with a circular shaft or axle and rotates over a common axis and comes with features to provide rotational force rather than linear.

- It is commonly called rotational force, which is torque, and this machine is used for designing and making steering wheels, mechanical gears, and also doorknobs.

Inclined Plane

- This inclined plane is a flat surface raised at a certain angle as a ramp. Basically, an inclined plane is a method of lifting high loads that are difficult to lift.

- The angle defines how much force is required to raise weight.

- The steep ramp needs more forces. The inclined plate helps us to apply low force through work distributed over a longer distance.

- The mechanical feature of an inclined plane is the ratio of the length of the slope to the height of the incline.

MA = L/h

- An inclined surface that has a longer length and slope provides high mechanical strength, so it is easy to move objects.

- The basic examples of inclined planes are wheelchairs and loading ramps on freight trucks.

FAQs

What is the definition of a simple machine?

- The simple machine is a mechanical device that varies force direction or magnitude. It is defined as a simple machine that uses mechanical features to increase force.

How do simple machines make work easy?

- There are 3 main methods where simple machines make working easy: through increasing distance by force applications, changing the direction of force applied, or multiplyingforce with the speed of energy applied.

What is a machine, and how does it make tasks easier?

- Machines make work easy through reducing the size or direction of input force. The machine does not vary the work done; the ramp is used as a simple machine. Ramps make working easy since the box is pushed through low forces for a longer distance.