There are different parts of a car that each perform certain operations. Brakes are also important components of a car that control the car’s speed. Normally, a car has two types of brakes: first, there are disc brakes, and second, there are drum brakes.

In this post, we will cover the features and working of drum brakes and practical applications. So let’s get started.

What is a Drum Brake?

- Drum brakes are brake types that operate through friction generated through pads that press externally in reverse to remove bowl-like components.

- In a drum brake configuration, shoes press on the internal surface of the drum. During externally pressing shoes, it is known as a clasp brake.

- In this combination, the drum is pinched between two shoes like a disc brake, and this combination is called a pinch drum brake.

- Drum brakes are part of small vehicles since they are a low-cost design compared to disc brakes.

- This bracket type is mostly used in the rear wheel as compared to the disc brake that is used at the front of the vehicle.

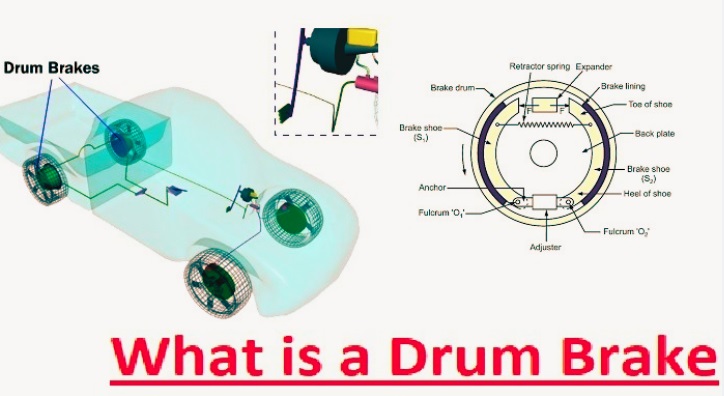

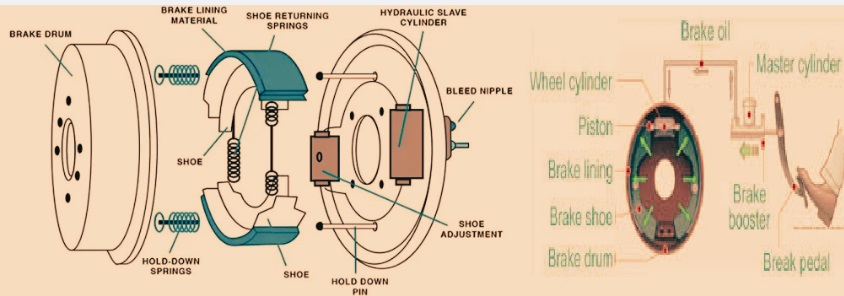

Drum Brakes Diagram

Drum brakes have rotors that provide rotation according to the wheels. for each drum brake shoe connected to the brake linings. Pistons press against the drum to cause a braking force and stop or decelerate it.

Drum Brake Parts

Drum brakes comesdifferent parts, and each performs functions

Read also Why Are My Car Brakes Grinding?

Backing Plate:

- Backing plates are used as a base for other components. Backplates provide a rigid structure for the complete assembly, supported by the complete structure, with protection from dust and other materials.

- This component manages the torque that occurs during braking, which makes it known as a torque plate.

- Its structure must be wear-resistant and strong for managing high pressures for backing plates.

Brake Drum:

- drum made with forged iron ironthat has high resistance to heat and wear. Its rotations occur through the axle and wheels. When the brakes are applied, the liner pushes radially opposite to the internal area of the drum and helps to manage smooth wheel and axle rotation through friction, also for the car. During friction applications, heat is generated.

Wheel Cylinder:

- One wheel cylinder controls the brake work on all wheels. The wheel cylinder has two pistons for operating the shoes.

- The leading shoe is also called the secondary shoe, and the trailing shoe is called the primary shoe.

- The hydraulic pressure of the main cylinder applies to the piston cup, applying force to the pistons on the shoes against the drum.

- When the brakes are released, the brake shoe springs get restored to their reverse conditions.

Return Spring

- return spring part of the drum brake that restores the brake shoe to its original position before pedal pressure applications. The return spring comes with 2 springs: the upper spring and the lower spring.

- The upper spring is a spring that exists on the upperside or below the cylinder wheel. The main function of the upper spring to restore the brake shoe position

- A lower spring exists adjacent and maintains two drum position brake shoes for the adjuster pressing

Brake Shoe:

- brake shoes made with two steel materials in a single assembly. Friction material is riveted on the linear table through adhesive. The online part is like a crescent and has holes and slots for different shapes to return springs and component adjustment.

Brake Shoe Holder

- • The brake shoe holder is a movable component that supports drum brakes. Brake shoe holders have different components, such as pins with springs and pressure plates. These components are connected to the backing plate.

Brake Shoe Adjuster

- The brake shoe adjuster exists on the lower side of the drum brake, and its design is like a screw on the adjuster. The brake shoe adjuster is the main part of drum brakes.

- The brake shoe adjuster is operated to manage the space of the drum brake pads and the drum surface during brake pedal movement

Read also Ceramic vs Organic Brake Pads: What’s The Difference

How Drum Brake Works?

Drum brakes work based on different braking mechanisms, and these are explained here.

Normal braking mechanics

- During the braking process, brake fluid faces forces from the cylinder to the wheel cylinder that press brake shoes for making connections from the drum to the drum surface. This process minimizes cylinder rotation that is connected with the wheel.

- That helps to reduce the speed of the car, and when the forces are reduced, it gets back to the original spring position again

Automatic self-adjustment mechanism

- When brake linings are damaged, the shoes cover a longer distance to get to the drum. For a system that has an automated adjuster, spaces reach a certain limit, and the slip adjustment system works through setting the position of the shoes to make them close to the drum.

- Adjusting lever rockers for adjusting the gear for a single tooth. The adjuster comes with threads that are like a bolt that help to unscrew during turning to fill the gap.

- During brake shoe wearing, the adjuster maintains the shoes close to the drum. Normally, the adjuster operated the vehicle’s reverse movement and the engagement of the brakes.

Emergency braking system

- Emergency brakes Mange brakes with steel cables in a combination connected with a pedal. In this system mechanical operations and sudden vehicle stops. In this process, cables pull on a lever configured in the brake and connected with the brake shoe. This process bypasses the wheel cylinder and manages the brakes.

Drum Brake vs. Disc Brake

The basic differences between disc brakes and drum brakes are as

| Feature | Drum Brakes | Disc Brakes |

| Stopping Power | It breaks or stopping power with high speeds |

It has good stopping power for highspeeds

|

| Heat Dissipation | itaffects due to overheating since it has lower heat dissipation features |

Its heat dissipation features are good and minimize brake fade

|

| Cost | low cost and easy to maintain |

expensive manufacturing and maintenance

|

| Maintenance | Simple maintenance easy to inspect |

complicated maintenance and difficult inspection

|

| Durable features | Durable with longer working life |

needing replacement

|

| Use | It is used for the rear wheels of small vehicles |

used for Front wheels and high-performance cars

|

Drum brakes types

Simplex brake drum

- It is a simple braking system that comes with a double-piston cylinder for forprssing brakeshows opposite to the drum. The cylinder of this brake exists at the upper side of the brake pads, and the lower side is compatible with the brake pad.

Duplex brake drum.

- This braking type has two single pistons, one on the upper side and the other on the lower. This drum brake has a cylinder moving on a single brake pad. Both brake pads become primary since they apply forces in the reverse direction of the rotation of the drum and make braking effective. During direction changes, brake pads are secondary.

Twinplex type

- This system is like a duplex braking system, with the difference that each cylinder comes with double pistons and causes movement of both brake pads.

- Its support is floating compared to a fixed point. So brake pads are secondary types since they provide force of rotation on the complete surface. During rotation direction variations, pads are secondary.

Duo-servo brake drum

- This brake has pads as the primary since it is operated and moves with a double-piston cylinder existing at the upper and lower ends of the actuating rod.

- In simplex operations, cylinders cause movement of both pads, and the primary pad applies force to the secondary pad with a rod, resulting in the secondary pad being the primary.

- This system causes the production of high frictional force to provide an effective braking system. Either rotation direction varies the brake pad and applies similar forces.

Drum brake disadvantages

- It causes high heat in the braking system that thataffect the drum and results in high vibrations during braking applications.

- Thermal expansion during hard braking increases drum diameter, so more pressure is needed on the brake pedal.

- Brake shoes cause overheating at the glazing point. High brake drum heating results from the vaporization of brake fluids.

- These brakes have difficult maintenance and take a huge amount of time since they have a complex design.

Advantages of Drum Brakes

- The construction of these brakes is low cost and provides high braking force. compared to a disc brake

- Drum brakes have a longer working life since they have a larger frictional area.

- They produce low heat, and their brake shoe can be manufactured.

- It has low maintenance frequency due to high corrosion resistance. Its wheel cylinders are easier to recondition than calipers.

Signs of a Bad Drum Brake

The main signs of faulty drum brakes are as

Difficulty during braking

- When drum brakes are not working, but sudden driving requires brakes, braking time increases since the brake drum is not working well. If the car does not accurately stop, it means the brake is causing faults.

- The car comes with brake drums on the rear wheels, and braking exists on the front side. so when both faults cause difficult braking

Brake pedal vibrations

- Due to brake drum deterioration, the pedal’s working effects are affected. Vibrations occur when force is applied to the pedal for the car to stop.

Braking Noise

- During braking, noise is created, which means the brake drums are damaged and not working. Heat is generated when braking since temperature increases, and brakes face more strain, which causes noises during contact between the shoes and the drums.

Difficult Parking Brake:

- The car comes with rear wheels for the parking brake. Most of the brake drums exist when braking is applied; parking brakes operate through brake drums to keep the car in position.

- Damaged drums do not store the car’s position during the parking brake; we feel looseness.

FAQs

What are the uses of drum brakes?

- Drum brakes provide constant braking force. Since drum brakes cause braking force in any direction. These breakers are part of the car’s rear brakes.

Are drum brakes good compared to discs?

- Disc brakes come with the same diameter but do not provide the same braking features as drum brakes. Drum brakes provide a higher friction area than discs and work longer. The manufacturing cost of drum brakes is low compared to disc brakes.

Do modern cars use drum brakes?

- Modern cars also use drum brakes. Since front wheels needed hard work, their disc brakes exist, but drum brakes are also employed. Sports cars also use parking drum brakes.

What are the limitations of drum brakes?

- Brake shoes needed more time for braking compared to disc brakes.

- It causes bad heat dissipation, which causes ventilation faults.

Are drum brakes safer to use?

- They have a larger frictional area, so they are safe to use. They are low cost and easy to use and provide high efficiency.

How long can drum brakes last?

- The normal working life of drum brakes is 150,000 to 200,000 miles. But according to driving conditions, these miles can be different.

Why does Toyota prefer drum brakes?

- Drum brakes have good emergency braking features, so they are used in Toyota vehicles. Drum brakes are also good quality; through using them, the rear disc produces a parking brake drum brake disc rotor.