A dynamic pump is a pump type that works through the following fluid dynamics. In these pumps, a mechanical actuator is used for transferring kinetic energy to fluids and increasing the fluid pressure. that increases speed for conversion in an increase in pressure with the use of a diffuser.

Dynamic pumps come with a continuous flow rate and are used for high flow rates. These pumps are used for oil, water, petrochemicals, sewage, etc. In this post, we will cover features and related factors. So let’s get started. What is a dynamic pump?

What is a dynamic pump?

- A dynamic pump is a velocity pump that provides fluid flow velocity for providing kinetic energy.

- When speed reduces before or when fluids are left in the pump and go into the discharge pipe, energy increases and is converted into potential energy or pressure.

- According to Bernoulli’s principle, kinetic energy is converted into pressure.

- Based on velocity gain, dynamic pumps also have further types.

- This pump comes with features that provide constant energy conversion of high energy into kinetic energy.

- High pressure causes high velocity.

Dynamic pumps working

- Dynamic pumps working based on fluid dynamics and energy transferred to fluid.

- In these pumps, mechanical energy is produced through an electric motor or an internal combustion engine that converts mechanical energy to a vane or a turbine.

- Through these actuators, kinetic energy is transferred into incoming fluids and increases speed.

- After that, accelerated fluids enter into diffusers that transform kinetic energy into potential energy or pressure.

- In the last, fluids with high pressure come out from the pump and go to the consumer circuit.

- So it is said that dynamic pumps increase pressure through converting energy into fluids.

- The main features of a dynamic pump are controllability and high flow production capacity.

Parts of dynamic pumps

- Dynamic pumps come with different parts, and each has its own working.

Impeller

- • The first main part of dynamic pumps is the impeller, and it is used for converting energy into fluid. An impeller has two subtypes, vanes and jets, according to design.

- • The vane impeller is readily removed through the middle axis of the impeller.

pump housing

- • The other part is the pump housing, a chamber used for directing fluid flow in and out from the pump.

Diffusers

- Diffusers exist on dynamic pumps that minimize the high speed of fluid coming from the impeller and transform it into pressure.

pump shaft

- The pump shaft is the part that makes the connection of the impeller with the motor shaft, sealing system bearing that holds the shaft at that point.

drive motor

- The drive motor is the mechanical energy source of the pump and is considered the main part of dynamic pumps.

dynamic pumpThe

- dynamic pump also has a valve that is used for reducing noise produced through the motion of fluids and transforms speed into pressure.

Types of Dynamic Pumps

Centrifugal Pumps

- This pump is commonly used. It is a simple design and an easy test. It has a strong design and low cost.

- When this pump is used, the pressure of the fluid increases from the inlet of the pump to the outlet.

- Pressure changes cause liquid to move in the system. This pump generated increased force through transmitting mechanical power from the motor to the liquid through a revolving impeller.

- Fluid reaches the middle of the impeller and releases over the blades.

- Centrifugal power increases the velocity of fluid and energy through the conversion of kinetic energy into force.

Vertical Centrifugal Pumps

- vertical centrifugal pumps, also called cantilever pumps. This pump operates with a shaft and maintains a structure that helps the volume of fluids to fall into the pit.

- This pump mode uses no filling container to cover the shaft at the position through the throttle bushing. This pump comes with a parts washer.

Horizontal Centrifugal Pumps

- This pump comes with two or more impellers. This pump is employed for pumping fertilizers. Its components are divided into pumps.

- All parts exist in the same casing and are connected on a single shaft. For a single horizontal shaft, there are 8 stages. Each stage increases head by the same amount.

- Multi-stage pumps can be single or double suction for the first impeller.

Submersible Pumps

- These pumps are also called sewage and septic pumps. These pumps are used for building services, industrial, rural, and rainwater recycling applications.

- This pump also has subsoil water features, black water, greywater, trade waste, and bore water.

- This pump comes with impellers with different designs, like closed, multi-stage, single-channel, cutter, etc.

- Its uses are based on applications like high flow, low flow, and high head.

Fire Hydrant Systems

- fire hydrant pump also called hydrant boosters, fire pumps, & firewater pumps

- that is high force. The water pump provides a high capacity of firefighting design through increased force in hydrant service, like the main, which is not effective.

- It is used for irrigation and also water transfer.

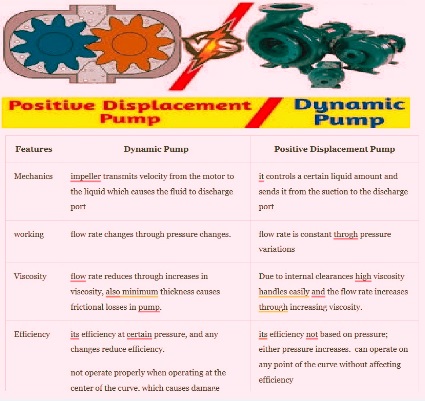

Dynamic vs Positive Displacement Pumps

| Features | Dynamic Pump | Positive Displacement Pump |

|---|---|---|

| Mechanics | impeller transmits velocity from the motor to the liquid which causes the fluid to discharge port | it controls a certain liquid amount and sends it from the suction to the discharge port |

| working | flow rate changes through pressure changes. | flow rate is constant through pressure variations |

| Viscosity | flow rate reduces through increases in viscosity, also minimum thickness causes frictional losses in pump. | Due to internal clearances high viscosity handles easily and the flow rate increases through increasing viscosity. |

| Efficiency | its efficiency at certain pressure, and any changes reduce efficiency.

not operate properly when operating at the center of the curve, which causes damage |

its efficiency not based on pressure; either pressure increases. can operate on any point of the curve without affecting efficiency |

| Suction Lift | standard models not produce suction lift, since self-priming designs exist and manometric suction life is provided through non non-return valve on the suction line. | it causes a vacuum on the inlet side, and has features of providing suction lift. |

| Shearing | High-speed motor provides shearing of liquids. Not preferred shear-sensitive mediums. | Low internal velocity causes low shear applied on pumped fluids. Good for shear-sensitive fluids. |

Advantages of dynamic pump

- • The dynamic pump comes with features that help it to be used for different industries.

- Dynamic pumps come with a small size and use a small area for installation. This pump also has lower maintenance and costs than other pump types.

- This pump has fewer rotating parts and is easily replaced and repaired as compared to other pumps.

- dynamic pump good for pumping fluids through low- to mid-level viscosity.

- This pump is also part of applications where low to medium flow rates are required.

Disadvantages of a dynamic pump

- The main disadvantage of a pump is improper alignment, which produces vibrations in the pump axis that affect working life.

- Its rotating parts cause damage to the impeller and wiring. Impeller damage causes losses that affect efficiency. Damage to the sealing wire results from leakage and minimizes efficiency.

- Pump bearings cause wear with high speed of rotation.

Applications of Dynamic Pump

- dynamic pumps employed for water supply and pumping process of crude oil

- its work in the chemical industry.

- It is part of household applications and the food industry.

- It is used for fire protection industries and petrochemical, hydrocarbon, paint, and beverage production.

FAQs

What is a dynamic pump in fluid mechanics?

- dynamic pump operated through dynamic interactions like velocity and pressure variations and moves fluid through the system by producing fluid velocity that is converted into pressure

What are the two main types of dynamic pumps?

- • The main types of dynamic pumps are centrifugal pumps and axial flow pumps.

Give a simple example of a dynamic pump in operation.

- dynamic pump used for water pipeline system. It moves water and andtransform velocity into pressure for a continuous flow of water from the water plant to our house.

What are some applications of dynamic pumps?

- Dynamic pumps are part of water distribution systems, industries for fluid transmission, the marine industry, cooling systems, and hydroplants for the transformation of kinetic energy into mechanical energy.