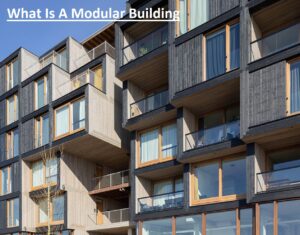

Modular construction is a process where a building is made off-site with the use of controlled conditions. It is built using the same materials and design as conventional construction, but it takes less time.’

The building is made in modules and placed in collaboration on site, showing the same design features and providing sophisticated site-building features without affecting quality. In this post we will cover details for modular building and related features. So let’s get started.

What Is Modular Construction?

- Modular construction is an off-site process where prefabricated modules are made with the application of controlled warehouse- and factory-based conditions.

- After the complication of fabrication, a single module provides easy transportation for the construction site.

- After that, these components connect and are assembled on the required site for making a complete and final modular building.

- Modular construction is a process used for assembling buildings through the use of prebuiltor preassembled distinct components that we install and fix for making the final assembly at the required point through Mobile Modular.

Modular Construction History

- Modular construction has been used for many years. The first modular building construction was made in 1624 when an English fisherman took his home to Cape Ann, which is a point in the United States.

- His house was disassembled and reassembled many times. The new generation of offsite manufacturing helps to work beyond older design processes and engineering sustainability.

- It is important for construction and also affects the new creation of buildings.

Features of Modular Construction

There are many features of applying modular construction features; some are explained here.

Fast Turnaround

- The main feature of offsite construction is that it reduces time for onsite work; we can also control project length. Subcontractors do not wait longer for another subcontractor to complete work.

- The final assembly is effective according to planning and uses advanced methods for providing fast construction on a given date.

Sustainable Projects

- It uses less energy with time for making modular buildings than conventionally made buildings.

- Modular projects finished in a short time that reduces energy for the project site.

- Based on WRAP details, 90 percent use fewer materials through the use of a modular structure.

- We can easily disassemble modular buildings and shift to any other location.

- It provides durable features and reusability with project sustainability.

Flexible Design

- Modular building provides flexible design for complicated structures. It comes with standard features; we can easily make complicated designs that need complex design. With that, it is used as temporary or long-term building projects and also for longer-term space operations.

Customization

- Modular construction also provides customization features, since it does not require thousands of dollars for getting a custom-designed space.

- Modular building comes with customized features that work well for operational requirements that are needed for organization.

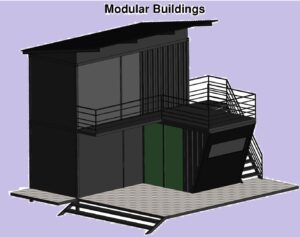

Modular Construction: Different Types

Modular construction comes in different types, and each has its own features. This process is used for different applications and works for different building types.

Volumetric Modular Construction

- This technique comes with the assembly process of enclosed and fabricated modules. In this process modules are configured through sides or in different stories, and as a result, they make the final assembly.

- The main feature of volumetric construction is its fully enclosed features. It comes with modules that are open-sided and sometimes partially open-sided and comes with non-load-bearing modules.

Commercial Modular Construction

- Modular commercial building creation comes with standalone buildings or complicated designs for different businesses, like manufacturers, hospitals, and other organizations. These modular buildings are made according to commercial building codes and work as permanent modular designs and temporary solutions.

Residential Modular Construction

- We can also use modular building for residential purposes. Homes and apartments made with this process come with different building codes as compared to commercial design and use the same process. We can assemble different parts of homes at factory design and send them to workers for final assembly.

Modular Construction Process

The modular construction process involved different steps that are explained here.

Project Design

- First of all, the design of the modular process was made for this purpose, and a drawing board was used. The basic difference with modular construction building is planning and accurate detailing since it is made off-site.

- The contractor gets details for the design from you, and industry standards with the budget are also discussed for the design of the new building.

- The stating of planning is important since it provides required details for final assembly with given timelines for projects.

Modular Building Technical Analysis

- When the design is finalized, check that design’s technical aspect. Building planes will not be approved without getting certification from engineers through a registered agency, and they will check your design for finding any errors and make sure that it is according to construction code.

- The International Energy Conservation Code Agency also makes sure that your design is not a health hazard and is according to safety measures.

- At the time of inspection, developers also get required permits for making the final assembly. Since it is important for modular construction, and that comes with getting site plan permits and construction permits, and also for plumbing and mechanical work.

Site Development

- After getting the permit, now your developer starts construction on-site according to the design. With prefabricated modules, site development is performed on-site.

- After inspection of the area, engineering started working according to the layout.

- Land needs to be excavated to the required depth, and it is also important for providing a proper drainage system. In the last step a strong foundation was made for putting up the building.

Module Manufacturing

- Module creation is performed, and the site is ready. It started with a welded steel frame where a complete module was applied, like base floors, walls, and ceilings.

- After finishing the skeleton, workers install electrical wiring and other plumbing work. It also includes interior designing, like paint, doors, and flooring.

Installation

- After completion of modules, it shifted to the site for final assembly. The final assembly was made at a predefined scale.

Modular Building Dimensions

Different modular buildings come with standard dimensions and are each used for different locations and states. Normally there are 5 common widths that are used for modular buildings that are 12 feet, 13 feet, 13 feet and 9 inches, 14 feet and 9 inches, and 15 feet.

The length of modular buildings is different according to locations and manufacturers. Some can be sixty feet, and some are made about 72 feet.

But according to codes for cargo height, a normal module lies below 13 feet and 6 incches height. For keeping modules strong in transit, some buildings are in the range of 8 to 9 feet

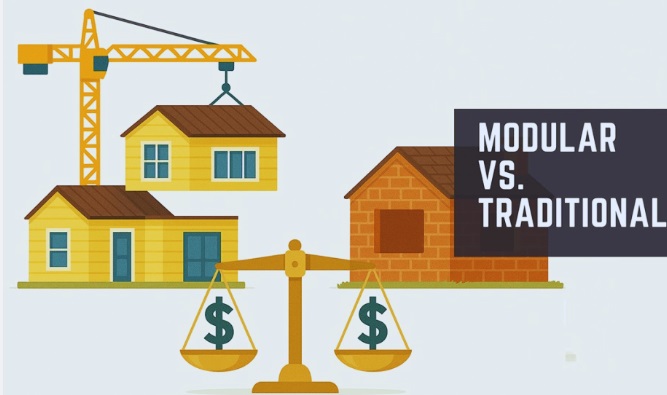

Modular Construction vs. Traditional Construction

There are many features of modular construction as compared to conventional construction methods.

- Weather and some other issues delay conventional construction, but factory-made buildings do not face this issue and do not cause any delay for project completion.

- The structure made at the factory comes with high-quality features, a good working process, and accurate monitoring. The team and workers work in comfortable conditions. It also provides flexibility to work 24/7 for completion of final assembly.

- It provides control work in the factor environment, reduces waste, and also controls the cost of the final assembly. You can save about 90 percent of the waste of materials compared to conventional building.

- The overall process was performed speedily, and the manufacturing of modules started with priority-based, then on-site processes.

- Modular construction also helps to make all parts of the building at one stop and takes less time for completing the final project.

- The best option for remote locations is to use modular construction as compared to on-site building, which is a difficult process there. For making remote building workers locations, it is also needed and causes difficulty for work.

- In the future, modular design will become important, and building relocation will become an environmentally friendly and low-cost option.

- Modular building provides complete assembly and component trailing easier than conventional building, assessing component by component.

- Different modular units made through the use of structurally insulated panels that provide good features for layer additions and are durable and also have good thermal insulation features and resistance for different weather conditions like moisture. As a result, the quality of materials increases.

- The main factor of modular construction is that it reduces more than 50 percent of your time compared to conventional builds.

Limitations of Modular Building

- The shifting and transportation of finished modular building parts needed huge space.

- Limitations for transportation also affect the size of modular units since transportation becomes difficult, which also restricts room size.

Modular homes vs. mobile homes

- The basic differences are building codes that follow construction, materials used, and purposes.

- Modular homes are made according to state or local building guidelines, while manufactured homes are made in a factory according to federal building guidelines.

- The codes that are according to modular home construction are like codes that follow construction site homes.

- In the USA modular homes are made based on the International Building Code, IRC, BOCA, or a code that follows through local jurisdiction.

- In some states, like California, mobile homes should be registered on a yearly basis, like standard trailers

FAQs

What are the uses of modular buildings?

- They are made for different uses, like sports halls, teaching areas, modular classrooms, and cafeterias. The flexible design of modular construction helps to provide effective space expansion and handles student requirements for handling disruption.

What is the useful life of a modular building?

- The accurate use and maintenance of modular building work for about 30 or more years; after that, the components need to be recycled.

Conclusion

- Modular buildings are prefabricated parts known as modules made in controlled conditions in off-site factory locations. Each manufacturing module is shifted on-site and then finally assembled. The modular building system is configured on permanent modular construction and temporary modular design.

- The PMCC building was made for a permanentarea of assembling. Relocating a building made with modular construction comes with mobility that helps to relocate and refurbish according to requirements. The common types of modular buildings are modular offices, portable offices, and mobile offices.