Spring check valves are a main part of industries that are used for high-pressure applications. A swing check valve provides reverse flow with horizontal forward flow through the use of a swinging flap. In this valve, the flapper swings away to provide forward flow of fluid or gas. For stopping fluid, the flapper swings back on the seat, closing the valve and reducing pressure.It has a larger flow capacity.

In this post, we will cover the detailed features of the spring check valve and how it works.

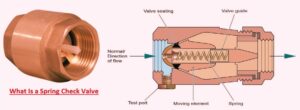

What is a spring check valve?

- the spring check valve used for providing flow in a single direction and andcotnrol reverse flow.

- It comes with a single inlet and outlet and uses accurate spring use for errorless operation.

- Each spring check valve shows features like the others that have arrows on the sides for flow direction indication.

- It is also called a non-return valve and has a spring, and pressure is applied on the disc for closing the valve and stopping reverse flow.

- It works based on differential pressure with flow from high to low pressure.

- high pressure on the inlet side called cracking pressure that helps fluid flow through the valve and controls inner spring strength

Key characteristics of spring check valves

fast response:

- the system of springsthat provides fast closing that controls reverse flow easily and quickly

Compact design:

- It is compact in design as compared to other spring-like swing check valves so that it can be used easily in compact spaces.

Horizontal and vertical connection

- It can connect horizontal and vertical connections.

Pneumatic systems:

- It provides airflow in accurate directions and avoids reverse flow that can be harmful.

Spring Check Valve Types

Axial Flow Silent Check Valves

- axial flow silent check valve comes with a disc connected at a point through a spring; that is the disc’s central point for smooth flow and a fast opening and closing process.

- The spring and disc are configured centrally in a pipeline that provides flow to move around the disc.

- axial flow A silent check valve has a higher cost than a conventional spring check valve and a swing check valve.

Ball Spring Check Valves

- • The ball spring check valve uses a ball to work as a sealing component that thatexists close to the inlet orifice.

- • The sealing seat has a conical tapered design for ball movement and provides a positive seal.

- If the flow cracking pressure is higher than the force with which the spring holds the ball, it causes the ball to push help fluid to flow.

- When cracking pressure reduces, the spline helps the ball move back for inlet closing.

In-Line Spring Check Valve

- This valve, also called a nozzle or silent check valve, has a stem and disc design over a spring.

- Both open when cracking pressure is higher than spring force; flow applies forces for opening disc.

- Due to decreases in inlet pressure, the spring applies force on the disc reverse to the orifice for closing the valve.

Lift Spring Check Valves

- This valve is put in lines in applications where a globe valve is used for flow control.

- It is also used in the x-axis and y-axis and mostly used with air, gas, water, and vapor lines.

- Flow enters below the seat of the valve and lifts the disc off the seat.

- For reverse flow, the disc is forced off the seat and stops reverse flow.

Non-Slam Check Valves

- CHECK valve control reverse flow through fast closing. This sudden closing, called slamming, occurs due to fluid flow changing direction or stopping.

- • The spring check valve has features to close fast before reverse flow that control slamming.

- The no-slam check valve comes with a spring that controls fluid pressure.

- for vigorous flow, through spring compression disc retracting easily.

- When flow is finished, the disc slowly gets reverse conditions.

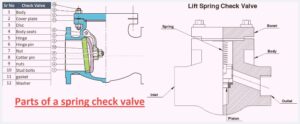

parts of a spring check valve

There are different parts of the spring check valve.

Valve Body:

- The external structure, or valve body, holds inner parts.

Seat:

- the surface over which the valve element seals for stopping fluid flow

Disc:

- • A disc is a moving part that stops or provides fluid flow.

Spring:

- It is used for providing the required force for the disc to return to closed closedconditons

Inlet and Outlet Ports:

- These parts help fluid to release or enter the valve.

spring check valve features

| Product Name | Water Spring Check Valve |

| Size | 1/2 -2, 1/2 -4 |

| Material | H583, CW617N, CW602N |

| Finishing | Sand-blasted |

| Threads | BSP, NPT |

| Working Pressure | 200 Psi |

| Spring | Stainless Steel |

| Temperature | -10°C TO 100°C |

Spring Check Valve Working

- the spring check Valve working is simple and easy to understand. If fluid flows in a certain direction, that applies force on the disc and reduces spring forces.

- When reverse flow occurs, the spring moves the disc back to the seat and closes the valve, stopping reverse flow.

- • The working of the spring check valve is defined in some points as.

- At the start, when fluid pressure at the inlet is higher than the force of the spring, the disc leaves the seat.

- when the disc lift opens the valve, that provides fluid flow from inlet to outlet.

- Until fluid pressure is in the accurate direction, the disc is open and the spring is in a compressed state.

- If flow stops or reverse flow occurs, pressure reduces downstream.

- for reverse flow Spring forces highly apply. So spring pushes back the disc on the seat seal valve and controls backflow.

Spring vs. Swing Check Valves

Swing Check Valves

- swing check valve used for horizontal or vertical upward flows since it has swing features of a disc. They do not provide downward flow.

- but can handle larger flow capacity, with that having low flow resistance and pressure.

- swing check A valve made with components lies in the valve body, which controls fluid movement in the body and leakage.

- The valve has a single-component design that provides a strong seal.

- • The disc in the swing valve has rotation features of 360 degrees and also provides accurate tuning settings. It is controlled through gravity if not flow exists.

- Swing check valves are not preferred for piping pipingapplications.

- It also produces noise when closing, for the metal-to-metal disc seat, which causes a ringing sound.

- It is used in toilets for flood prevention for sewage systems.

- It is a low-cost valve.

- It causes a pressure surge when fluid flow suddenly stops. that causes knocking noise in the piping system, resulting in pressure spikes that can damage the piping system

Spring Check Valves

- This valve is used for horizontal and vertical applications. In this valve spring system, maintaining the disc position when pressure reduces provides flow in any direction.

- disc seal valve opening through pressure of the spring.

- • The spring check valve also has resistance for flow and flow pressure that surpasses spring force for opening the valve.

- The working of the spring valve is noiseless, so it stops before reverse flow, avoiding water hammering.

- For avoiding water hammer, spring check valves called silent check valves provide noiseless working.

- so they are used for different applications, like closed spaces, certain dimensions

Spring VS Swing Check Valves;chart

| features | Swing Check Valve | Spring Check Valve |

| strcuture | Compact Design | heavy weight due to spring |

| Closure Mechanism | Swing Disc or a Flap | Disc pushed with Spring |

| Closure Speed | Slow speed | Quick |

| Pressure Drop | Lower drop | Moderate |

| Range of Flow Rate | good for low to moderate rate | for high-flow rate |

| Resistance to Clogging | Low prone to Clogging | Low prone to Clogging |

| uses | low or moderate-flow rate applications. | multiple applications. |

FAQS

What is the purpose of a spring check valve?

- • A valve is a device used for forcontrolling liquids, or gases. They are good to use for piping and processes that regulate flow and andpressure, start or stop flow, and control reverse flow.

What is the difference between a spring-loaded check valve and a check valve?

- • A spring check valve has more flexible features than a swing check valve. They are used for horizontal and vertical direction.

- Spring system maintains disc position when pressure losses provide single-direction flow

What are the three main types of check valves?

- Check valves are unidirectional valves that cause unobstructed flow in a single direction since pressure remains constant and protect the piping system from reverse flow.

- The main types of check valves are ball, piston, and stop check valves.

What is the minimum pressure for a spring check valve?

- The minimum pressure value is pound per square inch gauge or bars. Standard cracking pressure is 0.5 bar, 1 bar, or 2 bar. That is valve operating pressure.