The submersible pump, also known as a bell pump, is completely dipped in water for extraction. This pump is used during flooding conditions, like rising groundwater in basements or flooded locations.

Submersible pumps have different types and have different features according to water pumping features, like a clean water submersible pump, used for rainwater. Here we will cover details and features for different types and related factors. So let’s get started.

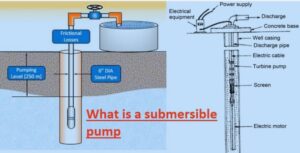

What Are Submersible Pumps?

- submersible pump The other name is Electric Submersible Pumps, which come with a hermetically sealed motor that helps the pump be completely immersed in liquid.

- These pumps have a centrifugal design and have effective design and need less energy for transmitting water in the pump than other pumps.

- Narrow submersible pumps have borehole features that make water extraction from narrow holes made into the ground about four inches

- fluid flow in a rotating impeller over the middle axis and propelled outward through use of centrifugal force, with the impeller’s vane tips.

- It is regulated with float switches that start working at different levels in the sump where the pump is connected.

- • The suction strainer at the lower pump strains solid particles.

- The main feature of the pump is that it stops pump cavitation, which is an error related to the high elevation difference between the pump and the fluid surface.

- These pumps have high efficiency and do not use energy for moving water in the pump.

- Some submersible pump types easily handle solid particles, and some handle liquids effectively.

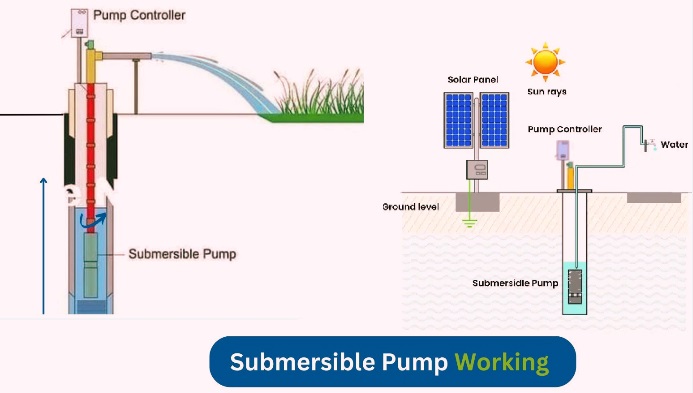

Submersible Pump Working Principle

- Electric submersible pumps are multistage centrifugal pumps that work in a vertical position.

- Fluids move through the impeller, and their kinetic energy is lost in the diffuser are converted into pressure energy.

- That is the basic principle of radial and mixed flow pumps. HSP hydraulic motors are used as a comparison to electrical motors and can be closed cycle or open-cycle.

- pump shaft connected with gas separator or protector through a mechanical coupling at pump lower part.

- Fluid goes into the pump through the intake screen and lifts through the pump stages.

- Its other parts are radial bearings aligned over the shaft length, giving radial support to the pump shaft.

- There is a screw-type submersible pump that has a steel screw as a working component.

- • The screw helps the pump to operate in water with high levels of sand and other impurities.

Basic working points

- The submersible pump is inserted in water and applies force on the water towards the surface.

- Water from the reservoir flows into the pump through the foot valve and collides with the impeller that comes with different fixed blades.

- impeller is connected with an electrical motor through shaft and moves in conjunction with shaft

- when water strikes with impeller blades, which convert the kinetic energy of the water into speed that increasing water speed.

- Water goes into the diffuser when flowing through the impeller, which transforms the speed of the water into pressure energy.

- The last diffuser increases the required water pressure, and high-pressure water released through the pump’s outlet valve.

Parts of a Submersible pump

different parts of the submersible pump areas

- Safety Rope

- Clamps

- Submersible Pump

- Check Valve

- Inlet and Outlet Valve

- Relief Valves

- Safety Rope

- Pump cable

- Flow Control Valves

- Impeller

- Ball Valves

- Tank Tees

- Pressure Gauges

- Sediment Filter

- Pressure Switch

- Torque Arrestor

- Drain Valves

Types of Submersible Pumps

There are different types of submersible pumps.

Bladder Pumps

- The condtions where low flow rate is needed where bladder pumps are best option to use bladder pump system that work effectively.

- applications of submersible stainless steel pump and coupled controller at proper locations; the bladder pump system uses regulated air pressure for direct water samples on the surface.

- The use of a disposable polythylene bladder in a submersible pump separates water and air mixture.

grinder pumps

- sewage grinder pumps used for working with raw sewage and solid materials

- Grinder pumps make soft solids through the use of cutting blades before wastage pumping.

- For larger levels of sewage waste, grinder pumps work like garbage disposals.

- that grind solids and waste materials into fine slurry and send towards the sewer system.

- This pump is used in residential locations and commercial applications and high-pressure sewage systems, where longer-distance pumping and high lifts are needed.

Deep Well Pumps

- This pump has all the features and the advantage of having a built-in check valve for controlling reverse flow.

- This pump is sealed and used for underground water applications, needs zero maintenance, and is made with corrosion-resistant materials.

- It used wells about 30 feet deep and higher based on conditions.

Dry Pit Submersible Pumps

- dry pit submersible pump used for dry well areas where wet well and dry pump chamber are parted. Before that, this pump was immersed in liquid.

- Dry pit submersible pumps are used as replacements for old centrifugal pumps.

Stainless Steel Pumps

- These pumps provide better working features than cast iron. It is coated with stainless steel and has good acid resistance.

- We can completely dip pump water.

Bottom Suction Pumps

- This pump is commonly used for pool, river, and mining dewatering.

- It comes with a sleeve below the pump. These pumps use water from the base and effectively help to provide quality cooling of the electric motor.

- This pump is also called an emergency pump, and this pump is more easily installed than other pumps.

Water Cooler Pump

- industrial water cooler pump also called homewater cooler pumps, used for irrigation pumps and industries

Submersible Utility Pump

- This pump has non-clogging and larger flow features that make it easy to use for different applications. such as water solidification pumping stations, sewage treatment, and overflow control

Mixed and Axial Flow Pump

- This is used for performing different functions and removing aquarium drainage and stagnant water at home and in outdoor spaces.

Crompton Submersible Pump

- These pumps are made with the use of cast iron and come with a single impeller.

- This pump has features for handling solids with a diameter of 30 mm.

- It also has a stainless steel cable-made hood.

Submersible pump cable

- Submersible pump cables are electrical conductors made for use in wet ground or underwater conditions and used for pump environmental conditions.

- A submersible pump cable is a special module used for submersible pumps in deep wells and in harsh conditions.

- For this purpose, the cable used needed to have a durable nature since the installation area and conditions are restrictive.

- Submersible pump cable used for fresh and salt water. It is also good for direct burial and also wells.

- These cables are installed in restrictive areas. Cable manufacturers considered these factors for getting high reliability.

- These cables come in different sizes according to usage and the pumping tools used by the installer.

- pump cable made with one or multiple conductor types and can be a flat cross section, and some have control wires and also a power conductor for the pump motor

. Factors for buying a submersible pump

Follow these points before the selection of a submersible pump.

- First of all, check the pump capacity. Normally, a pump has a 7,500-liter-per-hour per hour capacity, and some can flow 18,000 liters per hour. So select a pump according to your capacity requirements.

- Now another factor is to check the delivery head, which defines the highest height where water can rise through the pump. Some pumps come with a delivery head at 8 meters, and others can be 5 meters. So select according to your requirements.

- Check that the pump needs to be on and off automatically. that performed through float. For automatic mode, the pump does not have the feature of pumping the surface to make it dry; that is manual mode, which switches off for a given time.

- Make sure that all components are connected with the pump. Some pumps are easier to use than others, since they have larger parts. for accurate handling must check all required components

Submersible Pump Application

The main uses of submersible pumps are as

- Slurry pumping and sewage treatment

- Mining

- Firefighting

- Irrigation

- Drinking water supply

- Oil wells and gas

- Dredging

- Sump pumping

- Saltwater handling

Submersible Pump Advantages

high pump efficiency

- For pumping water at home, use a submersible pump that has high efficiency. Water pressure and design make the pump suck water with low energy use. which increases efficiency for reducing cost

low priming

- Some pumps needed proper handling before use. Since the pump works underwater, use it without priming. There is another method that can help you increase process efficiency.

Prevent cavitation:

- Cavitation is vapor bubbles making pumps move water, which causes a delay to stop and takes time to disappear.

- So design this pump such that the process occurs at the first point, providing effective working with good control.

reduced noise

- Submersible pumps work in underwater conditions; water helps to block the sound of the motor running. This feature helps to use wells where pumps can operate without affecting our work.

- They are also used in buildings without damage to filter the water.

FAQs

What are the uses of a submersible pump?

- submersible pump used for pumping well water for agricultural irrigation and pumping sewage.

What are the limitations of a submersible pump?

- Normally, submersible pumps have more effective than other types. It handles solids and liquids and does not use extra parts for water pumping.

- This pump does not need priming, does not have cavitation errors, and has high efficiency.

Can submersible pumps run dry?

- Yes, it can run dry for water levels less than the required level.

How long will a submersible pump last?

- • The working life of a submersible pump is about 8 to 10 years, and some work for 15 years.

How to select a submersible well pump?

Follow these factors before using the pump

- Type of water

- Suction depth

- Outlet size

- Borewell size

- Discharge height

- Float-and-flow switch

- Cooling system