Welding is a process that is a main component of metalworking and is used to join different parts of various metals. Welds come in different types based on the project, according to manufacturers. Tack welding is also a type of weld that is important, and here we will cover the details of this welding and its features with practical working.

What is tack welding?

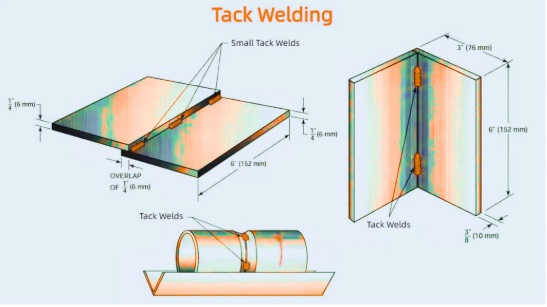

- Tack welding is a temporary welding process that uses low heat and a short arc for welding metallic components before final welding.

- With this help, we can make our welding process easy and simple since it controls metallic components at a certain point to avoid their movement before the sheet metal welding process.

- Tack weld helps to perform the required welding features. It also helps to finish tasks according to requirements.

- This main function is to hold components at the position where the welding process is performed. It ensures that the dimensions, distance, and location of the final weld are accurate.

- • A tack weld is a short-time weld but important for setting up the working component.

- This welding is part of making shoes and metallic boots.

Tack Weld Working

- The main function of tack welding is to set the accurate alignment of working components for performing final welding.

- It is an important part of the welding process, so we cannot perform it carelessly.

- If you perform tack welding improperly, it can cause errors and also affect your final work.

- We can use clamps for holding joints in tack welds. In some applications, magnets and clamps are used before tack welds.

- Some fixtures are difficult to hold joints through internal or external welding forces that require performing tack welds in the proper way.

- Welding consumables are used for removing clamps for checking joint conditions.

- When we apply a real weld over the joint line, the inner stress of metallic expansion and contraction causes joint separation, which can change the shape.

- So tack weld and bear these forces until the weld is completed.

read also:Why is Underwater Welding So Dangerous?

Tack Welding Importance

- The main functions of tack welding are as follows.

- It provides accurate material alignment by making connections of components at accurate points since it holds them.

- It also set the joint gap and maintained the proper joint gap without any changes.

- It provides strength of weld through minimizing distortion.

- It provides mechanical strength for assembly and ensures that assembly has its final shape without any changes.

- We cannot undo this weld that helps to provide control for the manufacturing process. So save extra charges and time spent for design.

- It also helps to increase the quality and precision of the final assembly.

Types of Tack Welding

Tack welding has different types, and each has its own features and working. Basic types of tack welding are as

Standard Tack Weld

- • A standard tack weld is good to use for providing support for the final weld assembly. This weld is a larger size that can easily manage materials to avoid any breakage. It is also good to make it in a larger size since the final weld is easily consumed.

Bridge Tack Weld

- These welds are used when materials are fitted and needed to fill the remaining gap. This gap is due to cutting material errors or manufacturers material distortion.

- In this welding, small tacks are used for each component in an alternative way. Alternative tacking helps to cool one side before re-tacking.

- This tacking work is done well through using MIG and TIG welding.

Thermit Tack

- This type of tack uses a mixture of pure magnesium metal, aluminum powder, and iron oxide powder. This mixture produces a high temperature of more than 4000 degrees Fahrenheit.

Hot Tacking

- deposition of excess filler metal applied in hot tacking in gaps of metallic components. The main use of this weld is to make connections of metal gaps. It is like bridge tracking that is different since a welder uses a sledgehammer for striking components in position when parts bridge with a weld.

Ultrasonic Tack

- ultrasonic tack process is used for making tacks through use of an electric or gas welding machine. This welding process makes short pushes that move over components with ultrasonic speed. After that, welders make molten materials that connect parts by pushing welding wire on the base metal.

Forms of Tack Welds

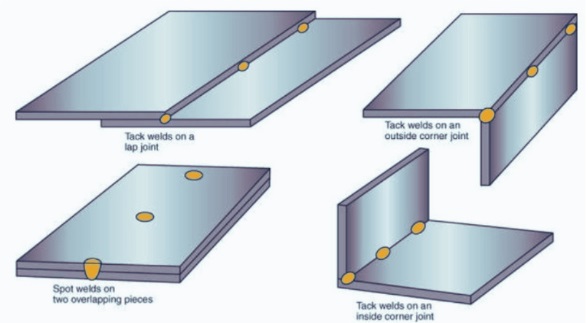

Square

- Tack welding makes the strongest weld. This method is used to make tack welds in a squared design and is used for making connections with two components at 90 degrees.

Vertical

- It is used for applications where two metallic components that are aligned at 90 degrees, where a tack weld is used from the upper to the lower part.

Right Angle

- It is used for making connections of metallic components at 90 degrees to each other. Tack weld used on the lower component

Right-Angle Corner

- The requirement where two 90-degree metals connected make a T-like design. We can make this welding for connection at a 90-degree

Tack Welding vs. Spot Welding

The basic differences are as follows.

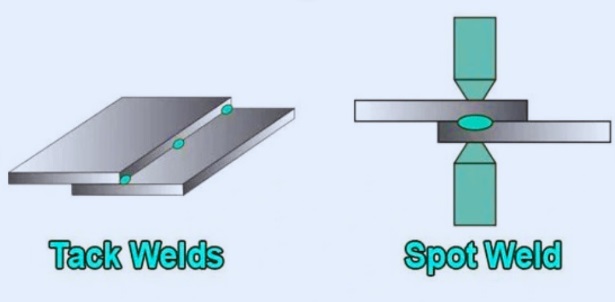

- Tack welding is used to make pre-welds, and spot welding is used to fuse two metals with each other.

- Tack welding is operated with filler materials for component connection, and spot welding is performed with a mixture of current and pressure applied on fused metals.

- Tack welding is used for different metals with different thicknesses. and spot welding is good for the connection of thin metal materials such as foil and wire mesh.

Advantages of Tack Welding

- This welding process makes sure that the design is accurate and working before the permanent weld.

- Tack welding is an easy and high-speed process.

- It helps to provide fast disassembly, and the joint can be connected in closed spaces.

- It also maintains joint gaps and avoids distortion at the time of welding.

- It is used for different materials and provides a proper alternative for holding parts.

Disadvantages of Tack Welding

- It makes weak connections made for a short time.

- It makes oxides and parts that need to be cleaned after some time.

- For tack welding different materials like hard steel, skilled welders are needed to avoid cracks.

- Some materials do not work well due to localized heating and cooling of tack welding.

- It is not performed well for larger components and areas.

FAQs

When to use a tack weld?

- Tack welding is used for providing short-term holding of components before final welding assembly. It is used for working on weldment and handling applications.

What is the difference between tack and full welding?

- Tack welding makes a temporary pre-weld, and spot welding is a technique used for joining two metals with each other permanently. Tack welding uses filler materials for the connection of metallic components, and spot welding is performed with current and pressure applied on metals to fuse.

What is the strength of a tack weld?

- The strength of tack welds has a direct relation with throat size and length. stronger tack weld through a larger throat or longer length.

What is the tack weld symbol?

- Tack welds do not have any special symbol. But we can find this weld-through circle put over or below on the reference line that shows tack welds.

What does a tack weld hold?

- Tack welds are used for making short-time holds for two metals in position before final welding and used alongside

What is a bridge tack weld?

- The bridge tack weld is the bridge’s gap between bevels without moving the root. It can be removed when no longer needed.

What is a good tack weld?

- The ideal weld that is used for providing accurate alignment for components helps to prevent metals from warping at the time of welding and maintains the joint gap. This can be done with proper heat, proper generation, and proper wire flow.

Can You Tack Weld Aluminum?

- Yes, we can tack weld aluminum, but use filler wire for this purpose. Since for welding aluminum, low melting temperatures make tack welding aluminum-based.

- It is possible to maintain a tight arc, use a sharp electrode, and check there is not a gap.

Is it possible to tack weld stainless steel?

- stainless steel tack welded, but the good thing is that the components are set up flush without a gap. Use a sharp electrode and ensure its position is less than 1/16” away from the joint, and for a fast burst,use high heat.

Is it possible to tack weld cast iron?

- • The cast iron welding process is difficult since it has a difficult metallurgical nature. It has a high carbon content that makes flakes of graphite and cast iron take time for slow cooling to avoid any cracking.

- Welds are made for high temperatures for cast iron, and metal faces this temperature for a short time.