The ball valve is a shut-off-type valve that operates with a rotating ball with a hole for controlling fluid flow. The ball rotates vertically with a handle for opening or closing.

Ball valves are easy to use, have a simple design, and provide a leakage-proof design. In this post we will cover details, features, and related working. Let’s get started.

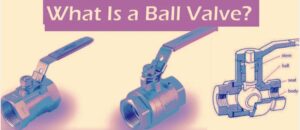

What Is a Ball Valve?

- The ball valve is a flow-controlling device that works by using a spherical ball with a hole in the middle.

- When the valve handle turns, the ball moves to align the bore with the flow path, helping the fluid to flow.

- When rotated vertically, the solid side of the ball completely stops the flow and makes a strong seal.

- The handle remains flat with the flow when open and at 90 degrees when closed, according to the current conditions of the valve.

- The off state 1/4 can be in any direction. A ball valve is longer lasting and works well after different cycles and provides easy closing after a longer time of non-use.

- ball valve operated manually, through lever handle or actuation.

- Actuation uses electric, hydraulic, or pneumatic power for opening or closing the wall.

- This process is good for controlling complicated operations and remote location control where manual operation is difficult.

components of a ball valve

There are different parts of a ball valve, and each performs certain operations.

Valve Body

- It is the main component of the valve, and other parts lie in this valve body, which performs on/off operations.

Rotary Ball

- • The ball is made with a hole for fluid flow. Ball direction is regulated through the stem.

Stem

- It makes a connection of the ball with the externally controlled system. like for a manual ball valve stem connected with a handle

Seats

- discs that exist between the body and the ball are called discs. Seats make a seal between the ball and the body.

Power Source

- • The stem of the ball valve moves manually or is actuated by a power supply. Manual actuation uses a lever that the operator controls.

- Automated power supplies are electric, pneumatic, and hydraulic.

Packing

- It is a seal over the stem that stops fluids from leaking.

Bonnet

- A bonnet is a body part that comes with a stem and packing.

Types of Ball Valves

There are different types of ball valves, normally defined based on different features.

Housing Assembly

One-piece

- It is a simple design in which the body is molded. A one-piece valve is low-cost but not repairable, so it needs to be replaced if broken.

Two-piece

- A two-piece ball valve comes with a design that has one end connection and a distinct component that covers the trim and other connection points.

- This valve is easy to repair and low cost. It also has repairing features.

Three-piece

- The 3-piece ball valve comes with 2 end caps and a body design. End caps are threaded to pipes, and the body can be disconnected for repair.

- Detachable features also need to be completely off the line. The use of an accurate ball valve housing is based on use.

types based on ball design

Floating

- In this design, a floating ball moves in the valve body in closed conditions and through controlling 2 seats.

- The shaft makes a connection with the ball at one end, stopping the flow when the valve is open.

- sealing based on fluid pressure. For closed conditions, inlet pressure applies force on the ball against the outlet seat to avoid fluid release.

- Pressure makes a seal; a floating ball valve is good for low to mid-level pressure for small diameters.

Trunnion

- A trunnion ball valve works as an extra shaft, which is called a trunnion.

- It holds the ball and controls its motion for rotation over the shaft axis.

- It comes with spring-loaded seats that are controlled with inlet pressure, applying pressure on the ball against the seal for strong closing.

types based on hole designs

Reduced Bore

- Reduced boreholes are common ball valves. bore is smaller than the pipe diameter, which causes friction losses.

- These losses are less than other ball types. The low cost of the reduced bore design is commonly used.

Full Bore

- full bore ball valve diameter equal to pipe diameter. that reduces friction losses that provide high flow capacity. but it is high cost.

types based on end connections

- End connections are points where the ball valve connects with pipes.

- The use of accurate end connections is important for easy connection and leak-free working.

Threaded

- • The VALVE body comes with threads on the inner side that are female and external threads that are male which make the connection with the pipe.

- Threaded connections are easy and commonly used for small valves where moderate pressure is required.

Flanged

- • The valve body comes with flat faces and bolt holes that are configured with flanges on the pipe.

- Gaskets existing between flanges provide a leakproof design.

- Flanged connections are used for larger valves and high-pressure applications.

1- vs 2- vs 3-piece ball valves

1-piece ball valve

- This valve design is a solid structure in a one-piece layout. It has a compact design and is used for low-pressure applications like plumbing connections.

2-piece ball valve

- The 2-piece ball valve comes with 2 parts. It can be disassembled without cutting the pipe and makes maintenance easy.

- • The valve comes with different sizes and pressure valves.

- It is used for industries for providing frequent servicing.

3-piece ball valve

- The 3-ball valve comes with 3 parts that have easy assembly and disassembly features. This design provides customization, since we can replace components.

- It is used for high-pressure applications and chemical processing such as oil and gas treatment.

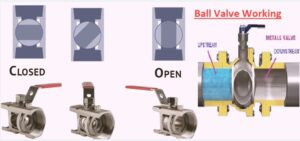

ball valve working

Open state

- If the valve handle rotates vertically, the ball rotates so the bore makes an alignment with the flow motion. This alignment feature helps fluid to move through the valve. Here handle is parallel with the pipe that shows the valve in open state

Closed position

- moving the handle again 90 degrees reverse direction in the result ball move that causes the bore to be 90 degrees in the flow direction and block fluid.

- In this condition, the handle at 90 degrees to the pipe and valve is closed.

types based on end connections

- End connections are points where the ball valve connects with pipes.

- The use of accurate end connections is important for easy connection and leak-free working.

Threaded

- • The VALVE body comes with threads on the inner side that are female and external threads that are male that make the connection with the pipe.

- Threaded connections are easy and commonly used for small valves where moderate pressure is required.

Flanged

- • The valve body comes with flat faces and bolt holes that are configured with flanges on the pipe.

- Gaskets existing between flanges provide a leakproof design.

- Flanged connections are used for larger valves and high-pressure applications.

1- vs 2- vs 3-piece ball valves

1-piece ball valve

- This valve design is a solid structure in a one-piece layout. It has a compact design and is used for low-pressure applications like plumbing connections.

2-piece ball valve

- The 2-piece ball valve comes with 2 parts. It can be disassembled without cutting the pipe and makes maintenance easy.

- • The valve comes in different sizes and pressure valves.

- It is used for industries to provide frequent servicing.

3-piece ball valve

- The 3-ball valve comes with 3 parts that have easy assembly and disassembly features. This design provides customization, since we can replace components.

- It is used for high-pressure applications and chemical processing such as oil and gas treatment.

ball valve working

Open state

- If the valve handle rotates vertically, the ball rotates so the bore makes an alignment with the flow motion. This alignment feature helps fluid to move through the valve. Here is a handle parallel with the pipe that shows the valve in an open state.

Closed position

- moving the handle again 90 degrees, reverse direction in the result ball move that causes the bore to be 90 degrees in the flow direction and block fluid.

- In this condition, the handle is at 90 degrees to the pipe, and the valve is closed.

Pneumatic ball valves

- pneumatic ball valve operated with air in a compressed state, which is good for fast cycling processes since it has a high-speed response.

- It is safe to use in hazardous conditions since it does not have electric components.

- It is mostly used for the oil and gas industry. Pneumatic actuators also have high torque and force features, so they are used for larger valve applications where high actuation power is needed.

- Its use of compressed air causes cost and requires high maintenance.

ball valve connection types

ball valve connected with pipes in different configurations for easy applications. different ball valve connection types used that are

Threaded connection

- It comes with male and female threads that come in tapered and straight designs. It is low cost and has easy installation and replacement.

- But it has high leakage for larger designs and needs a proper sealant.

True union connection

- It helps remove the valve assembly without affecting the pipe connected. The PVC piping system required maintenance and replacement of parts. Its easy assembly and disassembly make it useful for a longer life.

- It is a higher cost and heavier than threaded ball valves.

Glued sleeve connection

- It makes a connection between the valve and pipe through the use of adhesive materials. plastic piping system, and plumbing uses this connection.

- It provides a leakproof design. It is not used for high-pressure applications, and maintenance is difficult.

Hose pillar connection

- It comes with a barbed end for making easy and flexible hose connections.

- Low-pressure applications like garden hoses and temporary designs use this design. It is a simple design and provides easy installation. It is used for low-pressure applications that need clamps for a strong seal.

Materials of Ball Valves

Brass

- Brass is a commonly used material for ball valves since it has easy assembly, low cost, and a versatile nature.

- It has high resistance to temperature, pressure, corrosion, and microbial production since it has copper’s antimicrobial properties.

- It is safe for different chemicals and dezincifies in high-chlorine conditions that affect its strength.

- It’s this drawback that reduces cost, making it lightweight and easy to manufacture.

- It is good for food processing, chemical plants, and oil and gas applications.

PVC

- It has a low-weight structure and good corrosion resistance from different chemicals.

- PVC and CPVC are common since CPVC has high-temperature handling features.

- plastics used for water systems and chemical applications where moderate-level temperature and pressure is involved

Advantages of ball valves

- It does not use any lubrication and provides a strong seal with low torque.

- It is lower in cost than some other valves. with that has a longer working life when employed in accurate conditions and works for many years.

- They are also less damaged, and the plastic type is not affected by corrosion.

- It has easy connection features and quickly connects with plastic ball valves, which are lightweight and easy to manage.

- It is used for different industrial uses, like for handling liquids and gases.

- Ball valves maintain and control high pressure, volume, and temperature.

FAQs

Does the ball valve have partially open features?

- Ball valve not used for throttling purposes since it causes wear, noise, and vibrations. so a partially open valve is not used

What are the uses of a ball valve?

- Ball valves are part of pipelines to provide on and off control for different industries and are also used for irrigation systems since they have strong sealing features and fast operation.

Does the ball valve have control flow features?

- Ball valves provide control of flow and are not for flow regulation applications. It is good for applications where complete on and off features are needed.

Where are V-shaped ball valves used?

- V-shaped valves come with a good design and provide fine flow control features.

- It is used for throttling applications for flow rate partial regulation, then complete open or closed.

Why are oil and grease important for valves?

- oil and grease are used in industries to provide a strong leakage for shut-off valves.

Why do you need a ball valve?

- Ball valves are used due to fast shut-off features, low pressure losses, and good performance in different fluid control applications.

Which one is preferred, brass or plastic ball valves?

- A ball valve made with brass has high heat resistance, is durable, and is good for high-pressure and high-temperature applications.

- • The plastic valve has high corrosion resistance, low weight, and good resistance to chemicals.