A bearing is a mechanical component that is commonly used for different machine parts and instruments. It is used in different machines since they are important and can be said to be the building blocks of machines. Bearings help machine components to move in relation to each other. The main types of bearings are contact and non-contact. Contact bearing comes with a mechanical connection with devices that come with sliding, rolling, and flexural bearing types.

Non-contact bearing comes with liquid, air-mixed phase, and magnetic bearings. Static friction reduces in the absence of mechanical contact.

Here we will cover details for bearings and their features. Let’s get started with Introduction to Bearings.

What is Bearing?

- The bearing is a mechanical component that provides relative motion for required motion, and it also minimizes friction between moving components and parts.

- Their design provides free linear motion of the moving component, free rotation over a fixed axis, and avoidance of motion through controlling vectors of normal forces that are applied to the moving component.

- Some bearings provide required motion with reduction of friction.

- Bearings are defined according to working type and motion direction for load on parts.

- The word bearing is taken from to bear.” In simple words, with the use of bearing, different components or parts bear right.

- The simple types of bearings are bearing surfaces that are made into parts with different degrees of control for shape, size, and types.

- Some bearings are connected to machines.

What Is the Purpose of Bearings?

- The main objective of a bearing is to avoid direct metal connection between two components that have relative motion.

- It also reduces friction, heat production damage to parts.

- It also minimizes energy used since it provides low-friction rolling.

- Bearings also transmit the load of rotating components to the structure. The load is radial, axial, or can be a mixture.

- Through the use of bearings, we can control the motion of moving parts in a defined direction.

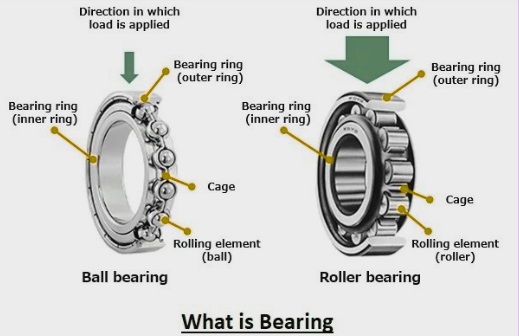

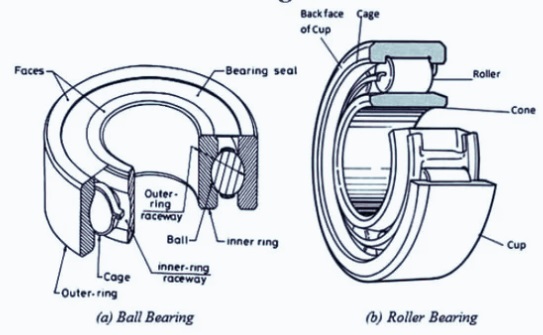

Main Parts of Bearing

Inner Race

- Inner race, also called the inner ring, is a component of a bearing that connects the rotating shaft. It comes with a smooth, accurate machine groove where the rolling component moves. When bearing work, this ring moves over the shaft, and control force is applied at the time of working.

Outer Race

- The external or outer race is static in machine components. It also has a groove that is called a raceway on which the rolling component lies. The outer race transfers the load from the rotating component to the remaining part of the machine.

Rolling Elements

- It is a ball, a roller that exists between internal and external races. The shape of this component is based on bearing types. Ball bearings have spherical balls, and roller bearings come with cylindrical rollers. These components reduce friction and provide smooth rotation.

Read also:What Butt Welding: Features, Process, Types, Joints & Uses

Cage (Retainer)

- The cage is the main part of the bearing, which rolls smoothly with proper space and avoids component bunching and provides smooth working.

- Cages made with metal or plastic, based on bearing types

Seals and Shields

- It is protection parts; seals are made to avoid contaminants such as dust and moisture from bearing and provide lubrication.

- Shields also have the same function but provide easy motion. Seals are used in bad or hard conditions, and shields are applied for low-contamination applications.

Lubrication

- Berains uses lubrication to avoid friction and smooth operations. Greases or oils are used for minimizing friction between moving components and to avoid any damage. It also provides cooling for bearings.

Raceway

- Raceway is the groove of internal and external races where rolling components move. It is accurately made for providing smooth motion and also load distribution in a smooth way.

Types of Bearings

Rolling Element Bearings

- Rolling element bearing comes with a rolling component like a ball design. That can roll without friction. Rolling element bearings are used for providing free motion of parts of machines in a rotational way.

- They also provide linear motion and transform rotational motion into sliding motion.

- The motion of an escalator looks like linear motion, but it is operated with rolls that move with motors.

- Reciprocating pump that transforms rotational energy of the motor into translational motion through linkages.

- Ball bearings are used for supporting motor shafts and also shafts of rollers.

Ball Bearings

- Ball bearing is a common type of bearing that is used in machines. It comes with many balls in a row that make a rolling element. They are configured between two annulus-design metallic components. That metallic component called races inner race that is easy to rotate and an outer race that is static.

- Ball bearings provide low friction at the time of rolling but have low load-handling features.

- Since it has a low area for connection between balls and races.

- It also supported axial loads in 2 directions with radial loads. Ball bearings are used for regulating oscillatory and rotational motion.

Deep Groove Ball Bearings

- It is widely used in bearing types. Balls in ring form are configured between two races to transmit load and provide rotational motion between two races.

- Balls are configured at position with retainer. It also has low rolling friction and has low noise features. It is good for high-speed applications.

- It is easy to install and needs low maintenance. During installation, avoid dents on races.

Angular Contact Ball Bearings

- In this ball bearing category, internal and external races move with each other over the bearing bearingringringring axis. This type is made for handling high axial loads in both directions with radial loads.

- As a result of internal and external races shaft axial load is transmitted to the housing through the bearing. This type of bearing is part for rigid axial.

- Angular connection bearing is used for automobiles, gearboxes, pumps, etc.

Self-Aligning Ball Bearings

- These bearings avoid misalignment between the shaft and housing that occurs as a result of shaft deflection. The inner ring comes with deep grooves, as deep groove bearings have two ball rows and external rings.

- The external ring is concave-shaped, and it provides internal ring freedom for rearranging automatically according to design.

Some other types of bearings are as follows.

Angular Contact Ball Bearings

- In this ball bearing category, internal and external races move with each other over the bearing bearing axis. This type is made for handling high axial loads in both directions with radial loads.

- As a result of internal and external races shaft axial load is transmitted to the housing through the bearing. This type of bearing is part for rigid axial.

- Angular connection bearing is used for automobiles, gearboxes, pumps, etc.

Self-Aligning Ball Bearings

- These bearings avoid misalignment between the shaft and housing that occurs as a result of shaft deflection. The inner ring comes with deep grooves, as deep groove bearings have two ball rows and external rings.

- The external ring is concave-shaped, and it provides internal ring freedom for rearranging automatically according to design.

Read also: What is Laser Beam Machining: Process, Types & Techniques

Some other types of bearings are as follows.

| Type | Details | Friction | Stiffness | Speed | working life | Uses |

| Plain bearing | It is part of rubbing surfaces with the use of lubricant, and some bearings employ pumped lubrication | According to materials used and design PTFE coefficient of friction is 0.05 to 0.35, according to the filler added | Good, it has low wear with slack exists | Low to high | Low to high according to application and lubrication | It is commonly used tyoe, provide high friction control.

Its working life vareis based on rolling component |

| Rolling element bearing | Ball or rollers make connection with rotating and static surfaces that move as compared to rubbing | Rolling coefficient of friction with steel value is ≈0.005 | Good, but has slack | Moderate to high | Moderate to high according to lubrication | It used for high motion laods as compare to playing bearings with lower friction |

| Jewel bearing | Off-center bearing rolls | Low | Lowin result of flexing | Low | Adequate | it used for low low load, high accurate working like clock. Jewel bearings is small |

| Fluid bearing | Fluid is added between two faces and held in by the edge seal | not friction at low speed. | Very high | Very high | Infinite in some uses and wear s hutdown in some cases. . | Damage fastly due to grit or dust or other contaminants. Maintenance not needed for continuous use. |

| Magnetic bearing | Bearing faces is separated with use of magnets | 0 friction for 0 speed,

with constant power for levitation, eddy currents produces due to motion ut are negligible if the magnetic field is quasi-static |

Low | No limit | Indefinite. Maintenance-free.) | Active magnetic bearings need high power. . |

| Flexure bearing | Material flexes for constrain movement | Very low | Low | high | High value based on materials and strain

maintenance free. |

Limited movement, no backlash,provide smooth motion |

| Composite bearing | It’s plain bearing design with a PTFE liner over the interface between the bearing and shaft, laminated metal backing. PTFE used as lubricant | PTFE and fillers used for handling friction a | Good, according to laminated metal backing | Low to very high | Very high; PTFE and fillers control wear and corrosion resistance | Commonly used, avoid friction, minimise stick-slip, PTFE control static friction |

How to select any bearing type

- Ball bearings are used for low- and medium-level loads, and heavy loads use roller bearings.

- If you have radial and axial component loads, use deep groove ball bearing spherical roller bearings.

- If there is not proper alignment between shafts self-aligning bearing can be used. Radial thrust breaking is used for mid-level thrust loads, and for heavy thrust loads, cylindrical thrust bearings.

- Deep groove ball bearings are part of high-speed projects, and for these applications, cylindrical roller bearings are also used.

- For rigid operations applications such as different tools, double-row cylinder roller bearings are used. Deep groove ball bearings are used for projects where noiseless operations are needed.

Applications of Bearing

| Type | Applications |

|

Ball Bearings

|

Electric motors, gearboxes, household devices automotive applications.

|

|

high-speed pumps, Machine tool spindles, and compressors.

|

|

|

fans, agricultural machinery, Conveyor belts, and textile machines.

|

|

|

Vertical pumps, crane hooks,

|

|

|

Roller Bearings

|

Gearboxes, electric motors, and construction devices

|

|

gearboxes, Automotive wheel hubs, and railway axles.

|

|

|

wind turbines, Mining equipment, and heavy-duty machinery.

|

|

|

ndustrial machinery, Automotive transmissions, i and aerospace components.

|

|

|

Special Purpose Bearings

|

CNC machines, and 3D printers robotic arms,

|

|

Turbochargers, and energy storage systems, flywheels,

|

|

|

optical systems, Semiconductor manufacturing, high-precision machinery.

|

Advantages of bearings

- Bearing main features are to reduce friction and use of power and provide high efficiency.

- They come in standard size, easily connect and disconnect also have simple repairing features.

- They are low-weight modules and have axial size in narrow modules with compact structure.

- It is highly accurate and provides a longer working life.

- Some bearings come with an automatic settings feature and are used for bulk production systems for providing stable and reliable operation with high efficiency.

- It has lower friction for transmission of torque than fluid dynamic pressure bearing.

- They have a smaller axial size than fluid dynamic bearings. They also make the same assembly for radial and thrust.

Disadvantages of rolling bearings

- Not but some bearings produce high noise and have a complicated design structure.

- Their cost is high .

- They can fail to operate in some conditions due to fatigue of the rolling contact surface irrespective of proper lubrication and installation.

FAQs

What are the main types of bearings and their uses?

- Roller bearings have features to handle high loads, and ball bearings are good to use for small loads. The selection of a certain load capacity for projects helps to use bearings.

What are basic bearing parts?

- Bearing comes with two rings having raceways, rolling elements in shape of balls.

- The cage that provides separation between rolling elements

What are the main 5 types of bearings?

- Ball bearings come with sets of balls.

- Roller bearings.

- magnetic bearing that uses a magnetic field.

- Flexure bearings that provide a limited rotation angle.

- Fluid bearings are defined with the use of a fluid used like a lubricant.

What are the parts of a bearing?

-

- Rolling bearing comes with inner ring, outer ring, rolling elements, and cage.

- The inner ring is configured on the axle, and the external ring has housing.

Which bearing type is mostly used based on features?

- Cylinder roller bearing are used for providing high radial load features. For bearing needed to support light loads ball bearings is good to use that are low cost.