A cam follower’s other name is “track follower,” which is a type of roller made for following a cam lobe profile. Cam followers have different designs; the most commonly used is the stud design. In this post, we will cover the detailed features of cams and followers and their importance.

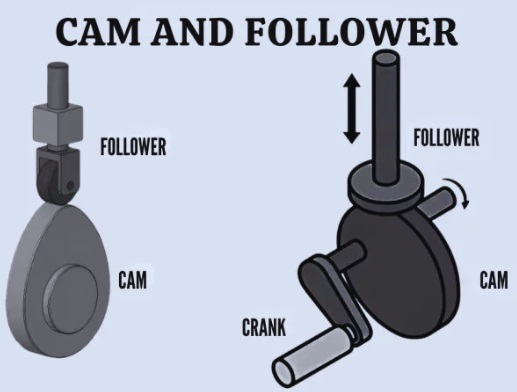

Introduction to Cam and Follower

- Cam and follower profile design connected shaft causes the rotation of the lever.

- Through connection on the shaft, transform rotational motion into linear motion.

- Their operations are such that cam rotation occurs, and the follower shows movement up and down, which is called reciprocating motion.

- The cam provides oscillation whose movement causes movement of the follower.

- Their structure is designed according to mutual relations or operations. The cam is working based on its own motion and the movement of the follower.

How Cam Mechanism works

- A cam is a rotating component that causes oscillatory motion of followers in a single assembly by making connections with each other.

- A cam is a mechanical component employed for providing the required movement of followers through making contact.

- Through this system, rotary motion is converted into linear motion. So it works as a rotating wheel, or like a shaft colliding with a lever at different points of circular rotation.

- Cams are designed like teeth, providing power pulses to the steam hammer.

- This structure is also part of the eccentric disc that causes the reciprocating movement of the followers.

- • A steam hammer uses a cam as a tooth to generate power pulses.

How the Follower Mechanism works

- Follower rotating component of the machine that rotates according to the movement of the cam, since a direct connection between them exists.

- The follower follows the vertical movement of the cam during cam movement in the reciprocating motion.

- The follower’s main purpose is to transmit motion to a certain part of a machine since its rotation is like circular arc.

- Followers directly connected to the cam for getting up/down movement. It connected with the surface profile as a loaded spring.

- follower to get complex motion through providing uniform velocity and uniform acceleration.

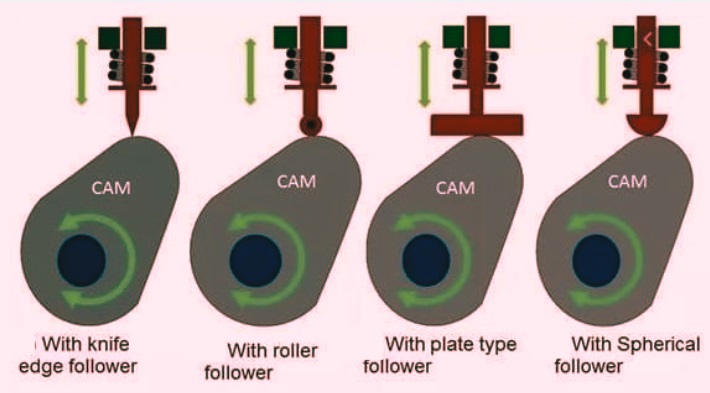

Cam Followers types

There are different types of cam followers; each has a certain operation.

Knife-Edge Follower

- Sharp-tipped followers make a connection to the cam, causing wear since they have a straight-edge design.

Roller Follower

- It has a roller mounted on the tip that minimizes frictional effects and wear of the cam.

Flat-Faced Follower

- Its flat contact design provides high-speed motion but faces high stress.

Spherical-Faced Follower

- • A curved contact follower minimizes wear and smoothly applies pressure.

Oscillating Follower:

- It transforms cam rotary motion to linear, oscillating through a vibratory process.

Reciprocating Follower

- It converts cam movement to back-and-forth linear motion.

Radial Follower

- This follower movement is configured to the central point of the cam, transforming the rotary process into a linear reciprocating movement.

Offset Follower

- The movement of this follower type moves away from the central axis of the cam, causing linear motion.

Cam Types

There are different types of cams, each performing certain functions.

Disk Cam

- Compact structure has an irregular contour and can be operated through radial motion followers for certain movements

Wedge Cam

- It is a flat slope design, and the linear movement causes the follower’s vertical oscillation through horizontal cam movement.

Spiral Cam

- It comes with a half circle, and it transforms rotational movement into a vertical reciprocating follower.

Cylindrical Cam

- It rotates on its own axis and comes with a circumferential outline. It has a carved groove to provide positive motion and provide follower movement over the parallel axis.

Heart-Shaped Cam

- It provides stability to the cam through the use of the pressure of the roller.

Translating Cams

- It provides horizontal rotation and controls spring-based followers. The groove cam was replaced with a spring.

Snail Drop Cam

- It causes follower movement all day and exists in chronograph watches.

Conjugate

- It comes with 2 distinct rotating cams; followers find cam profile errors through angle variations.

Globoidal Cam

- It is cylindrical in shape, having a concave design; it has machined grooves that cause a swinging movement of the follower.

Spherical Cam

- It is a sphere design and comes with a direct connection groove to the follower that moves certain locations according to cam rotation.

Dwell-Rise-Dwell-Return Cam

- Through one cam revolution resulted in different follower configurations like returns, dwells, rises, and dwells

Preloaded Spring

- This design has a preloaded compression spring in the follower for providing constant cam connection.

Different Cam & Follower Terminologies

Cam Profile

- • The point where the follower and cam make contact is called the cam profile.

Base Circle

- It is a small-sized circle of cam profile made from the rotation center to the cam.

Trace Point

- This point helps to trace the cam profile.

Pitch Curve

- This curve is made through supposing the cam is in a fixed state and tracing the point of the follower around the cam.

Pressure Angle

- It is made between the normal pitch curve and follower line motion.

Pitch Point

- The point where the highest pressure angle exists is called the pitch point.

Pitch Circle

- circle crosses pitch point

Prime Circle

- circle tangentially cut pitch curve called the prime circle and concentric with the base circle

Cam and Follower Working Process

- The working principle of a cam follower is easy. The process is based on their mutual work, like where camwork is, where followers operate.

- The cam is a mechanical part that causes rotation in a circle through the minor axis of the follower.

- It defines a mechanical component that provides reciprocating oscillation and linear motion towards the follower.

- The cam is an oval design, like an ellipse. If an oval-shaped cam is required, it shows that the motion needed an external triangle design.

- The external triangle burgee is important for mechanical operations. Cams have two categories, like single-head and multiple-head cams.

- The follower gets instructions from the cam that transfer motion towards the required movement.

Cam and Follower Advantages

- It transforms rotary movement into reciprocating motion.

- It provides required follower movement and handles high vibrations.

Disadvantages

- The cam is affected by wear, and its repair cost is high.

- It required high space for connection.

Application

- They are used for controlling the operation of inlet and exhaust valves.

- It is employed for wall clocks and part of the feed mechanism of an automatic lathe machine.

- It is used in gear-cutting machines and printing machines for screen printing. pushes the set position where printing is needed

- For hydraulic systems, provide main working textile machines that use cams and followers for cloth stitching.

- cam and follower used for automated machines, for motion of different automated parts

Where are cam and follower mechanisms used?

- Automobile engines (to operate valves)

- Textile machinery

- Printing presses

- Automation systems

What Is Cam?

A cam is a rotating element that gives oscillating or reciprocating motion to the follower, another element of this machine, by direct contact.

What Is A Follower?

A follower is a rotating or oscillating element of a machine that follows the motion of a cam by direct contact.

Where Are Cam and Followers Used?

Cams are commonly used in engines to control valves (in which the valve is the follower), sewing machines, children’s toys, and many other mechanical applications. The shapes of individual cams are designed to produce specific types of motion.

What are the types of followers?

- Knife-edge follower

- Roller follower

- Flat-faced follower

- Spherical-faced follower

What are the types of cams?

- Disk cam

- Cylindrical cam

- Translating cam

- Radial cam

What are the advantages of cam and follower mechanisms?

- Can produce complex motion

- Compact design

- Precise timing in engines

- Suitable for automated machinery

What materials are used for cams and followers?

Typically hardened steel, cast iron, or alloy steel for durability and wear resistance.

What causes cam and follower failure?

- Lack of lubrication

- Wear and fatigue

- Misalignment

- Material defects