Centrifugal pumps are used in different industries for fluid transmission. It operated through the transformation of rotational energy into kinetic energy, forcing fluid to move through the pump.

This pump is effective, reliable, and used for wastewater treatment, chemical processing, and water supply. In this post we will cover details for centrifugal pumps and related factors. So let’s get started. What is a centrifugal pump?

What is a centrifugal pump?

- Centrifugal pumps are used for fluid transportation through the conversion of rotational kinetic energy into hydrodynamic energy of fluid movement.

- Rotational energy is generated through an electric motor or an engine.

- In this pump, fluid enters the pump impeller or close to the rotating axis, and the impeller accelerates and moves radially outward into the diffuser, and here it is released.

- Centrifugal pumps are used since they have a high flow rate, abrasive solution, and mixing capabilities, with a simple design.

- centrifugal fan used for applying air handling units.

- If we use a centrifugal pump in reverse, it works like a water turbine, transforming the potential energy of water pressure into mechanical rotational energy.

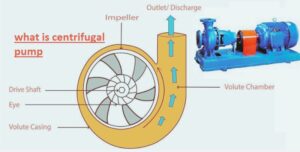

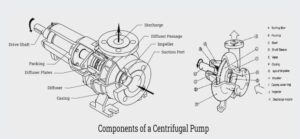

components of centrifugal pumps

Impeller

- An impeller is a rotor that is used in flow kinetic energy.

Casing

- It comes with fluid and works as a pressure containment vessel that controls inward and outward fluid motions in a centrifugal pump.

Shaft:

- impeller connected on the shaft. The shaft is used for the transmission of torque from the motor to the impeller.

Shaft sealing:

- Centrifugal pumps come with packing rings that control fluid flow leakage.

Bearings

- bearing control relative motion of the shaft and minimizes the friction of the rotating shaft and stator

Types of Centrifugal Pumps

- There are different types of centrifugal pumps according to liquid flow and their applications.

Single Stage

- In this pump, a single impeller rotates over the pump shaft, causing flow. In this design, the pressure range is 150M head, and the flow is about 600M³H.

- These pumps are clean or solid-handling pumps.

- Single-stage centrifugal pumps are also called “close,” “long-coupled,” or “vertical” according to installation and uses.

Close-coupled

- This type of pump comes with motors that are configured with a pump head and use an extended motor shaft where the impeller is mounted, or the motor and pump shaft are configured through stub screws.

Long Coupled

- A long-coupled pump comes with a pump mounted and configured on a baseplate, with the motor shaft and pump shaft connected through a rigid coupling.

- This pump is mostly used for heavy-duty applications where longer-term pump working is required without any hindrance with high pressure.

Multistage

- Multistage pumps come with different impellers that rotate in a ring area called that stage. Each impeller causes pressure for getting flow from the next impeller.

- A single impeller causes high pressure of about 1000M, and the moderate flow range is 1000M³/H.

- It is good to use for clean fluids.

Side Channel

- Side channel pumps are hybrid design pumps; they are like multistage pumps that come with many impellers, but they are self-priming and manage gases, so they are used for liquid fuels and uses where very low inlet pressure and low temperature exist.

- It is used for high-pressure applications of about 400M and low flows of less than 42M³H.

- It is preferred for clean fluids that do not have abrasive particles.

Self-Priming

- Centrifugal pumps lift water from a tank existing below the pump inlet without an extra device like a non-return valve on the inlet pipe.

- Self-priming pumps feature to draw water from tanks, where water bodies exist below the inlet, without an extra valve and handle entrained air.

- When the casing has water on first use, it starts priming through fluid contained in the pump head for producing a vacuum and releases air in the inlet pipe while working when fluid enters the pump head.

- Now pump starts operations like a normal centrifugal pump.

- It has lower efficiency than centrifugal or multistage pumps that handle solids without errors.

- The maximum flow value is 700 m³/h, and the head is 150 m.

Magnetic Drive

- Magnetic drive pumps come with different designs of pump heads than traditional pumps.

- • The pump shaft comes with the pump head through the rear port sealed with a mechanical seal.

- magnetic drive pump Make sure there is complete sealing of the pump head through the pump rotating with magnets set in the pump head and operated externally through the motor.

Split Casing

- They are also called double-suction pumps and come with an impeller that is made for producing high-volume flow.

- The impeller comes with a back-to-back design, where its design works like 2 impellers connected configured on a double volute.

- It is made for providing a flow of 6000 m³/h and heads of less than 200 m of low-viscosity fluids.

Working of a Centrifugal Pump

- Centrifugal pumps are used for inducing flow or increasing liquid from low level to high level.

- • The working of the pump is simple; it transforms the rotational energy of the rotor into moving fluid.

- Its impeller and casing are the main parts that are used for energy conversion.

- The impeller is the rotating component of the pump, and the casing is the airtight path that covers the impeller.

- In fluids, it comes in a casing, then falls on impeller blades and moves tangentially and radially in an outer direction till the impeller is in the diffuser part of the casing.

- When fluid flows through the impeller, fluid velocity and pressure increase.

Factors affecting centrifugal pump working

There are some important factors that have an effect on the working of the pump and must be considered before the selection of the pump.

Fluid Viscosity

- it resists shear when energy is given. A centrifugal pump is good for low-viscosity fluids since the pumping process produces high liquid shear.

Specific density and gravity of fluid

- Density of fluid is mass per unit volume.

- when fluid mass per unit volume and gravity of fluid is the ratio of fluid density with water density.

- It affects the input power needed for a pump to pump a certain liquid.

- If your fluid is not water, you must check the specific density and gravity of the weight that has an effect on the pump working.

Temperature and pressure

- The pump also works based on pressure and temperature and the main factor.

- High-temperature pumping needed special gaskets, mounting designs, and seals.

- The certain pressure valve for casing needed high pressure.

Net Positive Suction Head (NPSH) and Cavitation

- NPSH is a term that defines fluid pressure on the suction side of the pump for defining that the pressure is high for controlling cavitation.

- Cavitation is the creation of bubbles in liquids that produces in low-pressure areas on the impeller and can damage the impeller and provide a low-pressure rate.

- Make sure that the total totoalsystem net positive positivesuction head available is larger than the positive suction head required (NPSHR).

Vapor pressure of the fluid

- Vapor pressure of fluid is the pressure valve at a certain temperature where fluid is converted to vapor.

- It is defined for avoiding cavitation and also managing damage resulting from dry operation when fluid converts into vapor.

Features of Centrifugal Pumps

- main features of centrifugal pump areas

- It has low friction and magnetic coupling, so the breaking pump does not get overloaded and avoids damage.

- These pumps allow different mediums to flow and have high corrosion resistance that saves the pump from corrosive materials for a longer time.

- This pump also provides higher energy efficiency than other pumps. Its high efficiency makes it work for a longer time.

- Centrifugal pumps avoid pushing when other pumps generate pulsing flow.

- This pump has reliable features that make the pump work safely in different conditions.

- Its longer working life makes its pump lower than other pumps that need frequent maintenance.

- These pumps come in different dimensions.

- • There is an air gap between the pump chamber and the motor that controls heat transfer through working as a thermal barrier.

- It has drive seals that minimize chances of leaks. that helps to transmit hazardous fluids easily

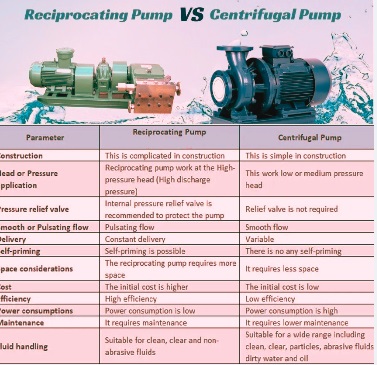

Reciprocating Pump vs. Centrifugal Pump

- • A centrifugal pump is simpler in design than a reciprocating pump. Centrifugal pumps have few components and provide easy repair.

- A centrifugal pump has high weight for certain discharge. A reciprocating pump has more weight with the same discharge.

- centrifugal pump not good for larger discharge but normal for pressure applications.reciprocating pumps for low-discharge features

- Centrifugal pumps use more floor area ad an strong base, and reciprocating pumps need a simple foundation with low weight.

- Centrifugal pumps have less wear and tear with raw water contamination with suspended solids than reciprocating pumps.

- Continuous flow occurs for centrifugal pumps with priming requirements, while reciprocating pumps have fluids in pulsed motion and do not use priming.

- Centrifugal pumps provide high operating speeds with low efficiency. A reciprocating pump provides high efficiency but is not good for high-speed functions.

- Centrifugal pumps needed lower maintenance and longer working maintenance than reciprocating pumps.

Centrifugal pumps vs Positive Displacement pumps

| features | Centrifugal pumps | Positive Displacement |

| Effective Viscosity Range | low efficiency with increased viscosity (max. 200 Cp) | high increases with high viscosity |

| Pressure tolerance | Flow changes with changing pressure | Flow is insensitive to varying pressure |

| Efficiency less at higher and lower pressures | efficiency is high with increasing pressure | |

| Priming | uses | uses |

| Flow | Constant | Pulsing |

| Shearing | High speed damages shear-sensitive mediums | Low internal velocity. Best for pumping shear-sensitive fluids |

limitations of a centrifugal pump

- proper working of centrifugal pump based on constant, high-speed movement of impeller.

- For high-viscosity fluids, pumps have low efficiency and high resistance, and pressure is required for getting a certain flow rate.

- Centrifugal pump used for low pressure, high capacity, and pumping fluids with viscosities in the range of 0.1 and 200 cP.

- Slurries, like mud, or highly viscous oils cause high wear and overheating damage.

- Positive displacement pumps work at low speeds and do not bear these errors.

- Pumped media that shows sensitivity for shearing is also damaged by the high-speed centrifugal pump’s impeller.In these conditions, a low-speed positive displacement pump is used.

- In dry condition, a centrifugal pump does not have suction like a displacement pump.

Summary

- A centrifugal pump works through rotational energy transmission from one or more rotors, or impellers. The process of the impeller increases the speed of fluids and pressure and moves towards the pump outlet. Its design is simple; this pump is easily operated and maintained.