Chain drive is the main technique used for power transmission and is part of the mechanical system. It comes with a flexible looped chain that is configured in a mesh design with sprockets for rotational motion transfer and power between components.

These features are used in different applications, such as bicycles, motorcycles, and industries, since they are highly efficient. In this post, we will cover details for chain drives and related factors. So, let’s get started.

What is a chain drive?

Chain drive is a method that is used for the transmission of mechanical power from one component to another. It was also used to deliver power to vehicle wheels, especially in motorcycles and bicycles.

It is commonly used in machines with vehicles. Power transfer with a roller chain, called a drive chain, that is configured over a sprocket and has gearing meshing teeth with holes in connection with the chain.

The gear turned, and it pulled the chain through, applying mechanical force on the system. There is another drive chain used, called a Morse chain, that has inverted teeth.

In some conditions power output is through rotation of the chain that is used for lifting objects. In other conditions, 2nd gear is used, and power gets through the connection of the shaft with the gear.

A drive chain is like oval loops; it also goes around corners through using two gears over the chain. Gears that do not provide power for transmission are called idler wheels.

Duplex chains are also chain types that come with two chains connected side by side that help to provide high power and torque.

Types of Chain Drives

Hoisting and Hauling Chain

- A hoist is a device that is used for increasing or reducing load through the use of a drum or wheel lifting mechanism around which a chain is wound. It works manually, electrically, or pneumatically and uses a chain or fiber for the lifting medium.

- Its common example is an elevator, where the carriage is raised or lowered through a lifting mechanism. Hoists are connected with loads through lifting hooks.

- This is used for hoisting and hauling and works at a velocity speed of 0.25 m/s. This chain has two further types.

Oval Link Chains

- Oval link chain, also known as coil chain, is good to use for low- to medium-load handling features and is normally part of a low-speed lift.

Chains with square links:

- This chain comes with square-shaped links. These chains are employed in hoists, cranes, etc. It is a low-cost chain compared to others.

Conveyor chain

- This type of chain is made for a conveyor system. It comes with plain bearings that are attached through connecting plates. Each bearing comes with a pin and bushing for rotation of the chain roller.

- This chain is used to lift and transmit things at a speed of 2 meters per second. It also has two subtypes.

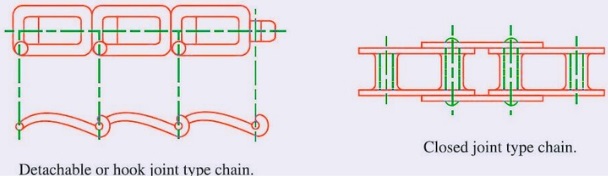

Detachable chain

- This conveyor chain is part of a conveyor that has a shorter length between power transmission points.

Closed joint type chain:

- This chain comes with a barrel and a link that are configured in one casting; the chain gets heated for high strength.

Cast iron is malleable and used for making conveyor chains. Those chains do not have uniform working features. The operating speed of the conveyor is 0.8 to 3 m/s.

Power Transmitting Chain

Power transmission chains are used to transmit mechanical power for small distances between shaft centers. This chain comes with good lubrication features. There are some subtypes of power transmission chains.

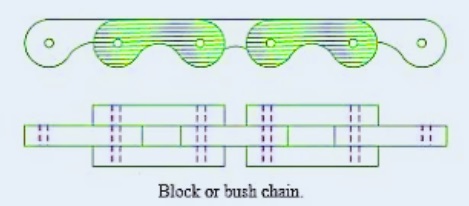

Block chain Drive

- This chain type is used at the starting phase of power transmission production. It produces sound when rubbed between teeth and the connection where the sprocket is close to the teeth. These chains are used for smaller speeds than conveyor chains.

Bush Roller Chain

- This chain is used for mechanical power transmission in industries and agricultural machines and is also used for conveyors, wire, printing presses, and motorcycles.

- • A roller chain comes with small cylinder rollers connected with each other by sides. It is operated with a toothed wheel that is a sprocket. It can easily transmit power.

- This can is small in diameter as compared to the height of the link plates of the chain. Link plates are used as guides when chains move over sprockets.

- This is used as a guide for supporting material that carried over tracks.

- It is also used for drives in single-strand standard series roller chains. The power rating capacity of this chain has features to handle different loads.

- Multiple-strand roller chains used for high power capacity without increasing linear speed.

Silent chain

- This chain is also called an inverted tooth chain. That is made for reducing the bad effect of stretching and providing noise-free movement.

- As a result of the chain stretching and the pitch of the chain increasing, the links ride on the teeth of the sprocket wheel as the radius increases. It will automatically correct minor pitch variation.

- It does not have any relative motion between the teeth of the inverted tooth chain and the sprocket wheel.

Engineering Steel Chain

- Engineering steel chain was first made in the 1880s and used for difficult handling and conveying uses. Engineering steel chains are part of conveyors and bucket elevators and also part of tension linkages.

- The main features of these chains are tensile loads and lubrication. The important factors for engineering steel chains are joint wear, bushing wear, and sidebars, which are important factors for conveyor chains.

Bicycle Chain

Different bicycle chains are made with carbon or alloy steel, and some are made with nickel plating that avoids rust. Chain drive mainly helped to make new types of bicycles in 1885. THat has two same size wheel. It has driving safety features that make it useful for bicycles.

This chain provides high efficiency since it helps to move the pressure point from the axle away, applying low pressure on the bearings and reducing friction on the wheel.

Automobile Vehicle Chain Drives

The chain drive system provides power from the differential to the rear axle of the vehicle. Automobile chains were commonly used for power transmission systems. It is used as a replacement for driveshafts and universal joints.

The design of chain drives is simple as compared to driveshaft and universal joints.

Belt Drive vs. Chain Drive

Belt Drive

- Belt drive is used to provide continuous and flexible transmission.

- The belt is composed of rubber or synthetic materials.

- It is more highly effective than a chain drive since it has low friction. It also needed low maintenance.

- It is noiseless and provides limited use in high-speed uses.

- Belt drives provide low-load-carrying features.

- It is low cost to make and provides a longer belt working life.

- Its high weight causes the belt to slip.

Chain Drive

- It is a discontinuous and rigid design. It is made with metal.

- It provided low efficiency due to high friction.

- It needed regular maintenance and tension features.

- It is high noise at high speed.

- Chain drives can easily handle different speeds.

- It has features to handle heavy loads and high costs.

- It is replaced after some time since it has a short working life.

- It slips less in high loads.

Drive Chain Advantages

- One chain can operate different shafts and also be used for long and short distances.

- It does not cause fire, and its design is compact and small in size.

- It works well in different temperature conditions. Its installation is easy, and it can handle corrosion.

- It does not cause slapping and operates well in wet conditions.

- Its efficiency is about 95 percent.

Drive Chain Disadvantages:

- The chain drive not used here needed slip-on-ness, and it also needed lubrication.

- It has a lower load cavity than gear drives.

- It works well in noisy and vibratory conditions.

- It is not used where accurate motion is needed. It also needed housing.

- It is not good to use for nonparallel shafts, and setting is needed for chain slack.

Conclusion

Chain drive is part of the mechanical power transmission system since it has different features like reliability, high efficiency, and the ability to transmit power over longer distances between rotating shafts.

It is also used in bicycles, industries, and vehicles. Chain drives provide low slippage and constant speed ratios.

For providing good working features It needed proper maintenance, like tension settings and lubrication.

FAQs

Does chain drive operate faster than belt drive?

- Belt drive is high speed as compared to other chains. Both come with their own features, such as belt drive high speed, but drive chain is effective and has the feature to handle high power output.

Are chain drives used in cars?

- Chain drive is used in different vehicles, cars, bicycles, motorcycles, etc. It is also used in older types of vehicles that provide durability and strength.

What chain types are used in chain drives?

- Roller chains

- Double-pitch chains

- Silent chains

- Leaf chains

What is the difference between chain drive and belt drive?

- Chain drive uses metal chains and sprockets and has durable features and no slippage. Belt drives operated fabric belts and noiseless chains that need less maintenance.

What to do to maintain a chain drive?

- If you have damaged sprockets and chains, replace them as soon as possible.

- Clean cane and use lubrication.

- Regularly check alignment and tension.

How many types of chain drive are there?

- Power transmission chain drive.

- Hoisting and hauling chain drive.

- Conveyor chain drive.

What are the limitations of chain drive?

- It is not operated with a non-parallel shaft.

- • Dry chains cause noise and also produce vibrations.

- • The chain also slips off due to improper alignment.

- It also needed constant lubrication and enclosure.

Why would a chain drive be used instead of a belt drive?

- Belts are good to use for low to moderate loads, and chains are used for heavy loads. Since it has high load-bearing features and torque capacity.