The diaphragm valve is the main part of industrial components for fluid control systems; its main feature is to control flow difficulties. This valve uses a flexible diaphragm for regulating fluid flow, which helps to provide corrosion resistance, contamination control, and accurate flow regulation.

Diaphragm valves come in different types, like PPH diaphragm valves and PVDF diaphragm valves. Here we will cover detailed features for the diagram valve and related working.

What are diaphragm valves?

- • The diaphragm valve‘s other name is the membrane valve, which is the elastomeric diaphragm valve that provides sealing from the seat for the regulation of fluid movement.

- A diaphragm valve comes with a body and two or more ports, a flexible diaphragm, and a seat over which the diaphragm closes the valve.

- Valve body made with plastic, metal, and other materials according to use

- This diaphragm, which works like a flow control system, has features of modulating, fluid separation, and stopping.

- This valve sets the set diaphragm position for controlling the flow rate of fluids.

- If the diaphragm is strongly pressed to the seat, the valve closes and the fluid stops.

- Design provides linear motion for controlling flow through the following linear motion system

- diaphragm valve, also called a membrane valve, that can easily handle different media like gases, liquids, and semi-solids.

- It is also used for industries for thick material movement control. Its simple design reduces sediment and biofilm creation, and part of the cleaning industry likes food.

- It is also used for wastewater management and provides good features for environmental care systems like water treatment.

- It is also part of the manufacturing and pulp and paper production industries.

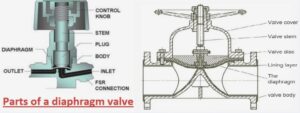

parts of a diaphragm valve

Bonnet

- bonnet is used as the upper covering of the diaphragm valve and bolt on body. Its working is to protect the compressor, diaphragm stem, and non-wetted parts.

Valve body

- Valve body is connected with the pipeline where fluid flow occurs. flow area in the valve body based on diaphragm valve types

Diaphragm

- In case of high flow rate, the diaphragm lifts and the valve is completely open. fluid flow below that diaphragm.

- It separated non-wetted parts from the moving fluid.

- So solids and viscous fluids are less affected by the diaphragm valve working

Compressor

- A compressor is basically a disc that exists between the valve stem and the diaphragm-compatible valve and distributes the forces of the stem for linear flow.

Stem

- It is a vertical shaft connected with a compressor that causes linear motion for moving the compressor and diaphragm.

- Diaphragm valves come with piston or threaded stems. The piston valve moves with the piston in the bonnet through the valve stem, working like a piston rod, that provides linear forces through fluid pressure

- • The threaded stem valve comes with a matching stem nut that uses torque for stem linear motion and also uses lubrication for easy working.

Actuator

- Actuator used for moving the stem, compressor, and diaphragm with each other.

- It provides torque for the diaphragm valve to quickly control the flow rate. different types of actuators used for diaphragms: Manual actuators, electric actuators, pneumatic actuators, hydraulic actuators, and thermal actuators

Position indicators

- a position indicator like a meter that helps to find the location of the diaphragm valve and whether it is open or closed.

- It is a light, stem, or switch. position indicator connected to different valves that shows the flow direction

Connection

- A diaphragm valve has different connection methods. Threads, compression fittings, clamp flanges, tube fittings, and butt welds make the connection of diaphragm valves with the pipeline.

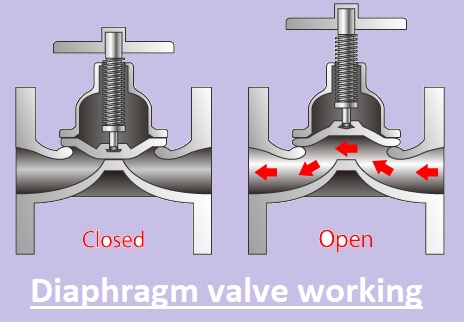

Diaphragm valve working

- The diaphragm control valve uses a plastic diaphragm that controls flow in the valve.

- A diaphragm valve comes with different turns, so the stem rotates more than 360 degrees for valve opening or closing.

- When operated, the diaphragm lifts the seat to control the flow rate. When the diaphragm closes, its edges gets force from the seat edges and diaphragm deformation.

- During diaphragm shape deformation, it accurately fits at the lower part of the valve seat and produces a strong seal

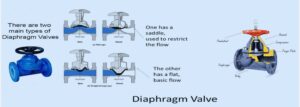

Types of Diaphragm Valves

Weir-Type Diaphragm Valves

- The weir-type diaphragm valve comes with a raised section in the valve body that the diaphragm makes a connection for controlling or stopping flow.

- This valve has good closing features and good applications for tight sealing.

- Weir design provides a tortuous flow path that provides pressure losses but has good goodselaing features.

Straight-Through Type Diaphragm Valves

- Straight-through diaphragm valves control the weir and provide a smooth flow path with low pressure losses. This valve provides flow velocity maintenance and reduces turbulence.

- This design provides easy valve cleaning and is good for viscous fluids or slurries.

Material of Diaphragm Valve

PPH Diaphragm Valve

- • The PPH diaphragm valve uses polypropylene homopolymer for construction, has good chemical resistance, and is a low-cost option.

- This valve has resistance for alkalies, acids, and organic solvents and easily handles 100 degrees without any damage.

- This valve is used for chemical processing and in industries where moderate temperature conditions are required.

PVDF Diaphragm Valve

- The PVDF diaphragm valve has better chemical resistance and high-temperature handling features than PPH.

- Polyvinylidene fluoride has good resistance to acids and bases while maintaining design at low temperatures.

- PVDF valves also work in a temperature range of

- -40°C to 150°C, so good to use for chemical processing and semiconductor applications.

diaphragm valve selection factor

Valve flow coefficient:

- • The flow coefficient of the valve is an important factor in finding the accurate size of the diaphragm to provide a certain flow rate of fluids.

- The flow coefficient of the valve increases when the valve is opened widely and the stem moves ahead.

- low coefficient value stops the flow and affects the working. An oversized or high coefficient causes energy waste due to high pressure losses.

Pressure losses:

- Pressure loss is the effect of reducing pressure from the valve inlet to the outlet side.

- If the ratio of pressure losses over the valve to net pressure losses is low, the flow rate varies less till the valve is closed.

- so diaphragm valve opens fast and is mostly used

Rangeability:

- It is valve features that provide control flow from high to low rate. This feature is based on actuator dimensions and accuracy, as well as valve body design, compressor, and diaphragm.

- The high rangeability defines the diaphragm valve, which easily handles a larger flow rate spectrum.

Media:

- medium corrosiveness features Also, define which materials are used for the valve diaphragm.

Temperature:

- Try to use such diaphragm materials that can handle different temperature conditions effectively.

Diaphragm Valve Vs Ball Valve

Different Valve Types

designs

Ball Valves

- • The ball valve is a spherical plug and seat as the main components. It comes with 3 different designs: full port, reduced port, and venturi port.

- The internal diameter of a full port valve is like the pipe’s inner diameter. Port is a single pipe size that is less as compared to the line size in venturi and reduced port types.

- O-ring seals and bolted packing glands seal the stem.

- The lubricant seal system for the valve has comparable features to the plug valve and is easy to access.

- According to valve port quantity and valve seats, a ball valve has one or more directional designs. So ball valves come with multiport valves like 2-way, 3-way, 4-way, or 5-way.

Diaphragm Valves

- This valve has a body with a weir in the fluid flow path; the compressor pushes the diaphragm from the weir, and the bonnet and handwheel hold the diaphragm and control the compressor.

- Diaphragm valves come with different end connections, like solvent cement joints, male sanitary threaded ends, and screwed ends.

working

Ball Valves

- • A metallic sphere moves in and out in the flow path and comes in ball valves, and it is good for the on/off of the ball valve.

- The metallic ball is configured straight to the flow path at the time of quarter rotation for flow stop and movement.

- pivoting hollow ball that has holes to regulate flow, and the ball valve rotates over 90 degrees to flow with the transmission medium that applies forces to the valve handle

Diaphragm Valves

- Diaphragm valves provide actuation and fast stoppage.

- It applies pressure on a flexible sheet that minimizes the fluid flow path area. while this valve has the longest cycle life.

Flow

Ball Valves

- ball valve is used for fluid flow motion through a system with stopping and starting

- It can have 1 to 4 ports, and ball ports come with a T-shaped design. The T design provides single-direction flow and the other side is closed or in two directions the same way.

- One-way direction of flow exists in L-shaped pipe.

Diaphragm Valves

- • The flow rate for the control valve is affected by the dimension of the valve opening.

- Linear and equal percent are used for measuring flow rate.

- disc movement accurately based on linear flow rate.

- The flow rate at 50 percent of the flow when the disc is 50 percent open

- Proportional flow rate is related to the change valve opening value in increasing terms.

Materials

Ball Valves

- ball valve made with different materials like brass, metal alloys, ductile iron, bronze, stainless and steel, copper, cast iron, and plastics.

- Most used ball valves are metallic, and elastomeric materials are used for trim.

- Different elastomeric materials, like Teflon, neoprene, nylon, and Buna-N, are used for making seats for ball valves.

Diaphragm Valves

- Different materials are used for diaphragm valves that can handle temperature, pressure, and other factors.

- Elastomeric material has resistance to high temperatures.

- Commonly used materials are butyl rubber, neoprene, Viton natural/synthetic rubber, nitrile rubber, white natural rubber, Hypalon, and white butyl.

- body of diaphragm valve made with different metal alloys, rubber plastic, and rubber

Valve Size

Ball Valves

- Valve sizing defines measuring flow through valve diameter.

- Two different-sized apertures are used for handling pressure reduction.

- In the case of a throttling valve, valve sizing is important for the pressure reduction factor.

Diaphragm Valves

- Using a diaphragm valve as a throttle device, size is the main factor. Intake and exhaust ports have accurate sizes, like open or closed systems, and do not have pressure losses.

- • The medium flowing in the system and the coefficient of flow define the valve size.

Advantages of the diaphragm

- This valve is good for throttling applications and has a clean design since there are fewer parts that stop biofilms.

- The diaphragm valve has good handling features for sticky and viscous media.

- It has low stem leakage, and it has low contamination. Maintenance is performed easily without affecting the pipeline.

Disadvantages of diaphragm valves

- Diaphragm valves work for moderate pipeline pressure and temperature conditions.

- It has limits for high hydrostatic pressures.

- It gets eroded when highly used in bad throttling applications.

- Weir affects the complete drainage of piping