Electroless nickel plating is a basic plating solution since it does not need any charge or catalyst. But it uses a natural chemical reaction that is applied to exposed parts of the base material. that provide high accuracy and customized thickness.

The solution comes with both nickel salt and a reducing agent and phosphorous content. A reducing agent is a component that releases electrons. As a result, nickel is applied over the substrate on the surface. This process is not needed currently since the reaction occurs chemically. So it makes a uniform coating. In this post we will cover details for electroless nickel plating and related factors.

WHAT IS ELECTROLESS NICKEL?

- electroless nickel plating, also called autocatalytic nickel plating. While electroplating, electroless nickel does not needed rectifiers, electrical current, or anodes.

- The deposition process occurs in an aqueous solution that has ions, a reducing agent, buffering agents, and stabilizers.

- A chemical reaction on the surface of the plated component resulted in the deposition of nickel alloy.

- Surfaces are wet with electroless nickel solution, come with the same plating rate, and deposit thickness is uniform.

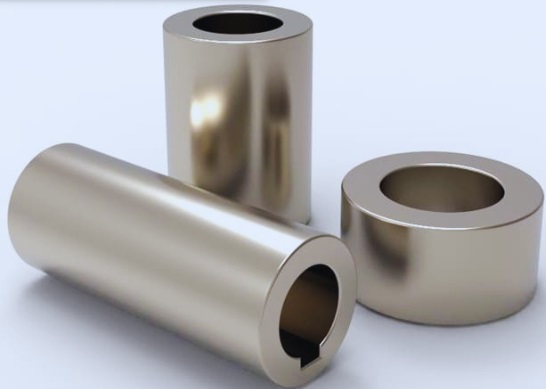

- This feature of electroless nickel helps to provide coating for the inner surface of pipes, valves, and other parts.

- This uniform thickness is difficult to get but can be achieved with other finishing methods. Electroless plating was first used in the 1940s by Brenner and Riddel. Not this process is used for different metals for the finishing industry.

- As compared to other metals, electroless nickel plating is a new method.

CHEMICAL REACTIONS

- chemical reaction that occurs with use of sodium hypophosphite i as reducing agent for electroless nickel plating is as.

Electroless Nickel Plating Process?

The electroless nickel plating process is a commonly used surface finishing process for different industries. It is part of vehicle, aviation, and manufacturing. As compared to conventional electroplating, electroless nickel plating is an autocatalytic chemical deposition process that makes smooth and long-lasting nickel phosphorous coating without the use of current.

This process involved different steps that are explained here.

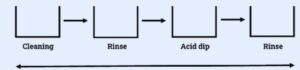

Surface Preparation

- First of all, in this process the surface is cleaned and pretreated for removing dust, oil, and other particles on the surface that can affect the electroless nickel coating.

- Different alkaline cleaners and an ultrasonic cleaning process are used for cleaning of surface grease, machining oils, and inorganic residues.

- Proper surface preparation for the plating process is crucial and has a significant impact on plating thickness, coating quality, and performance in corrosive conditions.

Activation

- After cleaning, substrate surface activation is started. In this phase an acidic solution like sulfuric acid is used that removes the residual oxide layer and shows an open metallic surface that has high catalytic activity.

- It is important for nonferrous metals and complicated alloys that provide an accurately applied electroless nickel plating layer on the base.

- Surface activation provides safe features from plating errors such as blistering or delamination, that have important effects on working and functionality.

Pre-Treatment

- According to substrate type, like steel, aluminum, copper, and plastic, the pretreatment method is used for providing adhesion and also resistance for corrosion and wear.

- Before the main plating bath phase, zincate treatment for the aluminum substrate is applied. This surface preparation process is important for making strong metallurgical bonding and uniform nickel deposition thickness that affect the working of electroless coating in different conditions.

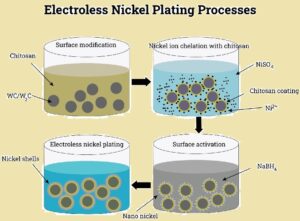

Electroless Nickel Plating

- At the time of the chemical nickel plating method, the pretreated substrate is submerged in a properly formulated solution that has nickel ions, a reducing agent, stabilizers, and proper additives.

- Reducing agents make interaction with nickel ions for starting controlled redox reactions, resulting in autocatalytic deposition of dense nickel phosphorus alloy layers or nickel boron alloy layers on the exposed surface of the substrate with cavities and complex geometries.

- As compared to electrolytic plating, electroless nickel finishes provide uniform thickness and features for high dimensional accuracy, good surface hardness, and proper chemical resistance.

Post-Treatment

- After completion of the electroless plating cycle, the plated material faces a post-treatment process that increases the high features. Rinsing and drying help to remove residual chemicals, and baking provides hardness and increases the crystalline structure of the nickel deposit.

- In some conditions, post-treatments like passivation, top coats or sealants are applied, and anti-corrosion agents are used to increase the working life and durability of the finished material.

- The use of accurate post-treatment is based on some factors like reduction of friction, weldability, or surface finishes for fulfilling medical or environmental standards.

types of nickel plating processes

The main types of nickel plating processes are as follows.

Electroplating

- Electroplating comes with the use of metal coating on metallic materials with the use of current. in this process, the material is connected with the negative point of dc current soruce and the metal deposited is connected with the positive terminal.

- electrolytic solution, which has metal ions, used as a medium where ions move and make connections with the material.

- As compared to electroless plating, electroplating uses current and also needs conductive materials.

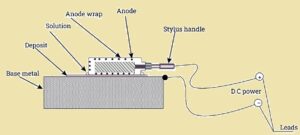

Brush Plating

- Brush plating is a process used for the application of metallic coating on certain parts of metallic objects with the use of an electroplating solution and a brush.

- In this process, the brush is connected with the positive point of the DC source, and the object for plating is connected with the negative pin.

- After that, brush in the electroplating solution that comes with metallic ions, and send these ions to the required part of the object. This method is used for repairing as compared to surface covering.

Hard Chrome Plating

- Hard chrome plating is used for the application of a chromium layer on a metallic surface to provide resistance to corrosion. Then, electroless nickel plating and hard chrome plating are based on current for transferring chromium onto the material. resulting in a durable, highly reflective finish that provides good wear and abrasion resistance. The use of hexavalent chromium is hazardous and also urges other methods.

ve finish

- as compare to other plating techniques, electroless nickel plating does not use current since it occurs with a reduction reaction. That makes a uniform coating on complicated designs and non-conductive surfaces.

- Electroless nickel plating makes constant thickness also in difficult points and also has resistance for wear and corrosion.

- The use of a plating process based on application and features.

Sulfamate Nickel Plating

- Sulfamate Nickel plating is a process that uses nickel sulfamate to get a coating with a dense design. This process makes a high tensile strength coating with good corrosion resistance. It can handle temperatures of about 1400 degrees, and this coating comes with a matte finish and is used for repairingdamaged parts.

Features of Electroless Nickel Plating

Corrosion Resistance

- Electroless nickel plating provides good protection from corrosion and also saves components from rust and other corrosion factors. This process provides a protective layer on materials that avoids moisture and corrosive components to apply to metal surfaces.

Wear Resistance

- This process also provides resistance for wear and increases working life in case of friction and abrasion. A nickel coating protects against abrasion and scratches.

Uniformity

- Electroless nickel plating provides accurate control for coating thickness and uniform design and, as a result, makes a constant layer. This accurate result provides protection for the coated component.

Adhesion

- The proper adhesion for different materials like metals, plastics, and ceramics—this type of plating reduces the use of extra primer and makes the process simple, reducing costs.

Surface Finish

- This plating process provides a smooth and constant surface finish, without error. It provides a good appearance and also increases function and working performance.

Conductivity

- Electroless nickel plating gives good conductivity and is good for electronic and telecom applications. It also increases the conductivity of different parts like connectors and pcb boards.

Chemical Resistance

- This coating also provides good resistance for different chemicals and is good for handling harsh conditions. This resistance protects components and increases working life.

Nonmagnetic

- Electroless nickel plating also provides nonmagnetic features that are good for components working in magnetic conditions, like medical devices and MRI machines.

Low cost

- Electroless nickel plating is a low-cost option for coating parts and components as compared to electroplating or vacuum deposition. This process is simple and uses fewer tools, which makes it low cost.

Uses of Electroless Nickel Plating

Aviation industry

- The aviation industry uses this process for handling corrosion and wear on aluminum parts employed in gear systems. With the use of the electroless nickel plating process, we get a constant, corrosion-resistant surface. It increases working life and minizes replacement of parts.

Electronics

- In the electronics industry, electroless nickel plating is used for providing good performance and reliable parts. PCB boards with this coating provide good soldering features, minimize error, and reduce manufacturing cost.

Automotive

- In vehicles different parts face corrosion and wear for cast iron brake parts. the use of this plating type, we can get a smooth and wear-resistant coating with good durable features and reduce chances of damage

Medical devices

- Different medical devices come with stainless steel components that face biocompatibility. The use of electroless nickel plating provides good biocompatible coating features that provide safety features for devices working in hard conditions.

Oil and gas industry

- Electroless nickel plating is used for coating of devices in the oil and gas industry and also for drill bits and pipe connectors that provide resistance for corrosion. such as plating drill bits with electroless nickel, increases working life, which reduces cost

Manufacturing

- for the manufacturing industry Electroless nickel plating is used for different tools like molds, dies, and rollers for providing resistance to corrosion. Such as the plating of rollers used in paper mills, which provides resistance for wear, resulting in a longer working life.