The foot valve is the main component that is part of a jet pump system like wells. Submersible pumps and jet pumps come with a foot valve on the intake suction line. Foot valves control water to flow in the opposite direction if the pump is off. In this post, we will cover details for the foot valve and its features.

What is a foot valve?

- An electric pump operates to transfer water from a lower level to a higher one. If the pump is off, water flows in the opposite direction due to gravity.

- So the main working of a foot valve is to avoid water reverse flow. A foot valve is a non-return valve connected to the pump suction for water flow in the back direction in case of pump failure.

- The valve keeps water flow in control in the suction pipe if the pump stops for proper prime, sustains the pump, and avoids pump damage.

- If the pump restarts, open the suction foot valve. The intake side of the foot valve comes with screws that control larger particles from entering the valve and affecting inner parts.

- A foot valve is used in ponds, pools, wells, and pump locations. The foot valve floor area is larger as compared to the pipe, which reduces head losses. The screen at the opening of the foot valve gets clogged with dust particles, like in wells, ponds, and pools. It is good to check and clean the valve for proper working.

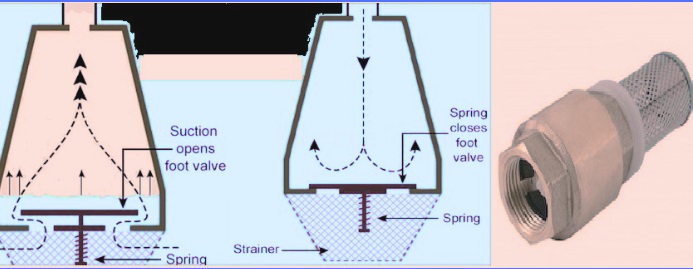

Foot Valves Working

The main working of a valve is to provide single-direction flow; a foot valve opens in one direction and closes in the reverse direction flow. So if used in a well, water can be extracted. Water that is in the pipe does not flow in the opposite direction towards the well. The main working process involved for a foot valve is as follows.

- Let’s suppose we have a shallow underground water well, and using a foot valve, there is.

- • The foot valve is connected at the pickup end of the pipe that is located close to the lower part of the well.

- If the pump is working, there is suction made that sucks water through the pipe. The foot valve opens when water flows in an upward direction due to the pressure of incoming water.

- If the pump is off, upward pressure does not apply. In these conditions, gravity operated on the water in the pipe, causing the water to move in a downward direction toward the well. So foot valves control these conditions.

- The weight of water in the pipe pushes downward on the foot valve. Since the foot valve is single-directional, it does not open downward direction. Pressure from water closes strongly, which prevents reverse movement to the well.

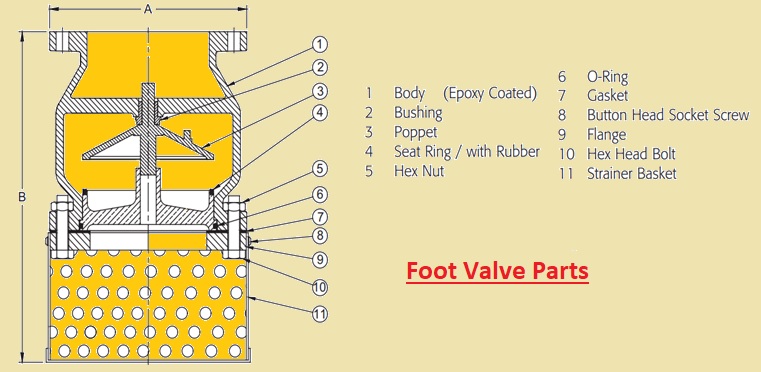

Foot Valve Parts

The main parts of foot valves are as

On/Off Component:

- This component opens a valve that can be a ball, membrane, or poppet made with different materials like bronze, steel, or brass.

Seat:

- This component is made with rubber and silicone, sealing the valve off in closed conditions and preventing fluid from leaking.

Body:

- The body comes with all inner components such as ports, discs, and seats. It is made with different materials like brass, bronze, cast iron, and stainless steel.

Strainer:

- This component is made with a plastic sieve. It filters particles and avoids clogging.

What is the purpose of a strainer on a foot valve?

- The strainer is the main part of the foot valve. When foot valves are used on ponds, wells, and pools, they can get clogged. The foot valve strainer filters larger particles and sediments that come with the suction line and clog the foot valve and damage the pump.

- Strainer made with plastic, brass stainless steel. Plastic strainers are used for small tanks that are light applications, and for heavy-duty devices, stainless steel strainers are used.

Why Are Foot Valves Needed?

- Foot valves are important since they avoid damage to water pumps that can occur due to dry runs and prevent energy waste. This valve is the main component of all water pumping systems.

- If you have a condition where water is pumped from sumps on the ground to water tanks on the upper floor, there is a need for a high-power electric pump. This pump operated by generating suction that applied force to water in an upward direction through a pipe to a tank on the upper floor.

- When the pump is running, there is constant water flow in the form of a column in the pipe due to the suction created. If the pump is off, the suction is not shown, and gravity applies to the water column.

- If you do not use a foot valve, water will flow in a downward direction in the pipe back to the source. As a result, the pipe is empty of water and filled with air.

- When the pump is on, air in the pipe opposes water flow, and also if the pipe is in water, it does not move in the pipe.

- These conditions cause a dry run that damages the pump if not properly handled.

- • A foot valve is used for solving this problem; it does not allow backflow of water if the pump is off.

Where to Use Foot Valves

- • A foot valve is a check valve that is part of a pump system. It is used for different conditions in homes and industries.

- Foot valve used with pumps that pump liquid or gases.

- Foot valves are used in ponds, pools, wells, and locations where pumps are used.

- In industries, these valves are used for sump pumps and intake pumps used for rivers and lakes and also in pneumatic brake lines of trucks.

- Foot valve for keeping pump primed, providing liquid flow in, and controlling outward flow. Screens exist that cover valve openings that get clogged and are used for water extraction from ponds.

How to choose the right foot valve?

- Different conditions are involved where foot valves are used… For applications where single liquid flow is needed, a foot valve is used.

- High-quality foot valves conserve energy and protect water pumps from damage, increasing working life.

- So use a quality foot valve since it is difficult to access for repairing after installation.

Foot Valve Materials

Foot valves are made with the use of different materials like

- Brass

- Plastic

- Cast iron

- Copper

- Nickel

- Rubber

- Stainless Steel

- Aluminum

- Carbon steel

Foot Valve Features

The main features that help to use a foot valve for different applications are as

- It has easy installation features, and some foot valves come with self-tapping male and female threads.

- It has inner balls that provide fast sealing and valve reaction.

- It has flexibility for use in different types of water pumps. They are used for wells and sampling and purging of volatile organic compounds.

- They are low-cost types of valves and made with cast iron, bronze, and PVC.

- They work longer if submerged in water.

- Foot valve connected at 90 degrees with an arrow that directs liquid flow.

How deep should a foot valve be?

- The foot valve is connected at a maximum of 25 feet at an angle of 90 degrees below the suction pipe of the pump inlet. The foot valve screw is not configured at the lower part of the tank or well for high working efficiencies.

FAQs

Define foot valve” and its uses.

- The foot valve is a type of non-return valve connected at the end of the pump suction in water or the lower part of pipelines for avoiding water moving backward when the pump is not working.

Why is a strainer used in a foot valve?

- • A strainer stops dust particles and sediments that come up from the suction line, clog the foot valve, and affect the working of the pump. It helps to get effective operations and increases the working life of the valve.

When should we clean the strainer?

- Set a proper timetable for checking and maintenance based on the foot valve’s working load, uses, and water if free from debris.

What is the difference between a foot valve and a check valve?

- Foot valve goes to the end of the suction line pump. Check valve movement at the end of the suction line, in the center of the suction line, and where it was needed. The foot valve comes with threading on the outer side and a check valve on both sides.

What is the fault or error with the foot valve?

- Foot valve comes with three main faults: disc flutter, wire drawing, and sediment buildup in scree. For solving the first two faults, the foot valve needed to be repaired, and the third can be solved without pulling up the pipe. So solve the issue of sediment creation. Good.

What is the difference between a non-return valve and a foot valve?

- • A non-return valve is made to keep pumps primed, and a foot valve is used with a filter to avoid dust particles entering the pipeline and pump.

Where is a foot valve connected?

- • The foot valve connected at the well jet pump, and it needed to connect lower to the well suction line piping. Like a check valve, a foot valve’s working is to prevent water from moving back.

Is it possible to use a check valve and a foot valve together?

- Using only one valve is best for a pump system. The foot valve is connected at the inlet to the suction turbine line, jet pumps, and centrifugal pumps. The check valve is put close to the discharge of a submersible pump.