Gate valves are commonly used for a water supply system. It is also called a linear motion isolation valve, and its main function is to stop and provide flow motion.A gate valve comes with a closing component moving in the flow stream that provides off features and works like a gate. gate valve used for separating a certain part of the water supply system when maintenance is needed.

In this post, we will cover detailed features of the gate valve and related factors. So let’s get started.

What is a gate valve?

- Gate valves are also called sluice valves or knife valves. It is basically a control valve that controls or allows medium flow.

- gate valve operated with a flat gate for controlling flow between pipe flanges.

- A gate valve is a full-port valve that comes with the same diameter of pipe where fluid flow occurs.

- so the gate valve has lower pressure losses than the butterfly valve design.

- The main working of a gate valve is as a blocking valve and to provide fluid flow with on-off features.

- Its simple design features make it useful for industrial uses.

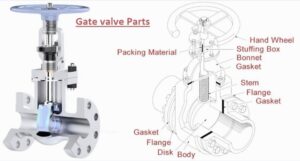

Gate valve Parts

Body:

- • The valve body is used for pressure retention and also connects and holds other components like the stem and disc.

- It also provides a path for flow in the valve; end connections are piping that is threaded or of the welding type and according to the size and pressure of the piping system.

- valve body made with different materials like cast steel, alloy steel, and stainless steel according to requirements

Bonnet:

- It also has a pressure-controlling valve part. that is also called a cover. It connected with the system through welding, bolting, and threading for the valve closing design.

- For the gate, the stop diaphragm wall comes with an opening valve stream pass.

Disc:

- It is used for throttle flow and stop flow. for a ball valve disc called a ball. The disc exists as a static wall seat when the wall exists in closed conditions. It moved away from the valve seat through the motion of the valve string.

Seat:

- It is the main part of the valve that controls and affects the valve leakage rate. The main part of the valve body is made of metallic rings or non-metallic rings.

- Each valve comes with one or more seats. For check valve design and globe valve construction, it has a single seat.

- While a gate valve has 2 seats, one is on the upstream side and the other is on the downstream side.

Stem:

- A stem is basically a shaft, and the valve stem transmits the transmission of motion of a disc plug for closing and opening of the valve.

- The stem is connected with the valve handwheel on one side and the valve disc on the other side.

Manual actuators

- The actuator is the working principle that controls the valve working. It is connected with the stem and disc.

- It is manually operated with a handwheel, gear, chain, and manual lever and works with a motor.

Gate valve working

- gate valve operated with handwheel, wrench, or actuator. The wheel is connected to the valve stem and transfers rotational energy.

- When the gate valve opens, rotations of the handwheel move the threads of the gate stem in the gate and also for closing.

- Rotational force moves the gate valve wedge up or down.

- For underground gate valve connections, an extension spindle is connected that provides easy access to the valve.

- gate valve connected with pipeline where it is open or closed since it operates for these two conditions.

- motor gate valve used for frequent valve and remote valve operations

Gate valve types

Solid Wedge Gate Valve

- It is a commonly used valve type since it has a simple design and high-strength features.

- the valve having a solid wedge connected in any direction and employed for different types of fluids.It is also used for turbulent flow.

- for high-temperature applications, A solid wedge causes a thermal locking system.

- Thermal locking is a process where the edge gets stuck between seats when the metallic component expansion occurs.

- solid wedge gate valve used for moderate to low pressure and temperature conditions

Flexible Wedge Gate Valve

- A flexible wedge is a solid disk that cuts over the perimeter.

- These cutting features are of different sizes, depths, and other dimensions.

- The shallow, narrow cutting on the wedge area provides low-flexibility features that provide continuous strength.

- The deeper and larger cut on the wedge increases flexible features and affects strength.

- This design enhances seat configuration and provides leakproof features.

- It also increases working conditions for thermal binding features.

- Flexible wedges are also part of steam systems.

- Thermal expansion of the stem line distorts the valve body that causes thermal binding.

- A flexible gate makes the gate flexible when the valve seat compresses as a result of the thermal expansion of the steam pipeline and avoids thermal binding.

Split wedge gate valve

- • A split wedge disc comes with two solid components and holds with each other through a certain process.

- For one half of the disk not in accurate alignment, the disk can freely sit on the seating area.

- A split disk comes in a wedge-shaped disk. That disk is spring-loaded since it makes a connection with seats and provides bidirectional sealing.

- • A split wedge is good for handling non-condensing gases and liquids for different temperature conditions.

- Easy movement of the disc avoids thermal binding and also comes with a closure for the cold line.

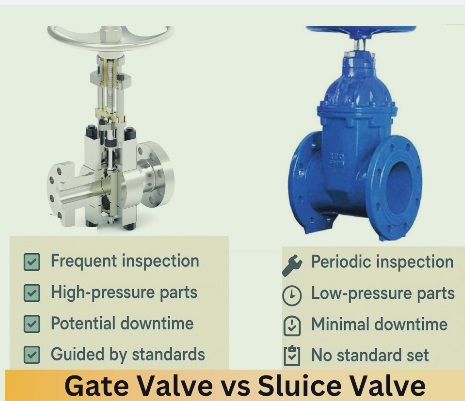

Gate Valve vs. Sluice Valve

Design

- These two valves are used for flow control of fluids in plumbing applications. but they come with different designs.

- A gate valve comes with a gate-like wedge that moves up and down to control fluid flow.

- A wedge provides sealing features for two seats on any valve body end.

- When the wedge is lowered, fluid can easily flow; when it level increases, it does not flow.

- Due to strong sealing, gate valve is good for applications where the fluid needs to be completely off.

- A sluice valve comes with a cylinder-like disk that opens or closes the low by moving.

- As compared to a gate valve, it comes with one seat that is rubber-lined.

- This feature makes it good where low flow rates are needed, like in irrigation systems.

Material

- The other feature for the selection of gate valves and sluice valves is the material used for construction.

- Gate valves are made with different materials like brass, bronze, stainless steel, and cast iron.

- Materials used are based on applications and conditions where the valve is used.

- sluice valve made with copper, PVC, etc. It is also made with cast iron and used for drainage applications.

dimension

- The dimensions of the valve are important for finding their role in plumbing requirements.

- • A gate valve has different dimension options as compared to a sluice valve.

- It has a size of 0.5 to 24 inches and is good for proper flow rate.

- Sluice valves are small in size, and their size is 10 inches.

Maintenance

- • The gate and sluice valve needed accurate maintenance to provide proper working.

- • The gate valve comes with a complicated design that needs proper cleaning and inspection to avoid corrosion.

- Sluice valves are simple in design and need proper service for smooth functions.

- For accurate working of the valve, some important parts like valve levers and rod extensions are used for accurate valve operations.

Gate vs Ball Valves

| Features | Gate Valves | Ball Valves |

| Flow Control requirements | it used where strong off and low pressure is needed | ball valve used for fast operations and has featurs for moderate throttling. |

| Water Hammer | it provides a slow-opening and closing process that minimizes water hammer. | Fastly close that has chance of water hammer. |

| Size | bore sizes more 2 inches. | 2 inches or below. |

| Space Constraints | Gate valves use more space due to their design. | it is a quarter-turn valve, so it fit in applications where space constraints is a factor |

| Operating Environment | used for high-temperature and high-pressure. | provide a strong seal for gas on a long-term basis. |

| Maintenance | more maintenance since have high wear and tear on the gate and seats. | Less maintenance can wear with a faster rate in throttling |

Selection factor for gate valve

Connection dimension:

- The connection size must be according to the pipe size connected.

Max pressure at 20°C:

- High value of pressure can affect the valve and also minimize working life.

Compression class:

- Compression calls are maximum pressure valves that can handle normal working conditions.

Handwheel height:

- A handwheel exists over the gate valve body, so its effect is important for closed and open positions.

Valve bore

- Inner diameter of valve is also important before valve selection

What are brass gate valves?

Brass is a famous housing material that is used for gate valves since it has different features.

- It has high resistance to water corrosion and is best for plumbing applications. Its high resistance makes it a longer-working valve, needing less maintenance and replacement cost.

- Brass also provides good thermal conductivity, which makes it useful for temperature conditions.

- It also easily manages different temperature conditions without any effect on sealing and expansion and contraction features.

- It is higher cost but easier to buy than other materials that have corrosion resistance, such as stainless steel, so overall it is a low-cost option.

- Brass is a good design and provides eye-catching features.

- Brass is a nonferrous metal that does not cause sparks. This feature makes it useful for flammable gases, which exist since it prevents ignition.

- Brass has natural antimicrobial properties, which is good for potable water applications because it reduces bacterial growth.

Gate valve advantages

- It has low pressure losses and easy installation, and working time is low.

- It has low wall resistance for fluid.

- Its opening and closing features are easy and commonly used in industries for steam, oil, and other medium flows.

- It is also used for forgranualr solids and high-viscosity materials.

- It is also used for venting and low vacuum systems.

- • The gate valve comes with dual flow directions. and not the flow direction of media.

- It is used for pipes where flow direction changes.

Disadvantages of Gate Valves

- A gate valve not used for controlling fluid flow, with that having slow operations.

- It takes more time to open and close.

- when it is partially open, it causes high noise, and its repair is also difficult

Gate valve application:

- gate valve used for different fluids like fuel gas, air, and steam, also for hydrocarbons, and any other services.

- It is used where high pressure and temperature are involved.

- certain gate valves used for slurry and powder manufacturing, that are knife gate valves.

- at low pressure and temperature are commonly used, like water distribution pipelines and fire protection systems

- The petroleum industry also uses this valve

read also