An infrared heater is a heating component that comes with a high-temperature emitter that sends or transfers energy to low-temperature bodies in the form of electromagnetic radiation. Emitter temperature defines the range of infrared radiation for peak wavelengths from 750 nm to 1 mm.

For the transfer of heat there is no connection needed between mediums. Infrared heater working can be performed in the atmosphere. In this post we will cover details for the infrared heater and its features.

What is Infrared Heating?

- Infrared heating uses electromagnetic waves for transferring energy to materials and minimizes the use of heat for air between the infrared source and the object.

- The range of infrared energy is 0.7 microns (µ) to 6 µ. We can control energy level through selecting a certain wavelength range that helps to heat the component in an effective way.

- This process transfers heat to materials without affecting the temperature of the surrounding air. So infrared heaters are effective in their working.

- They operated with electrical power, natural gas, and a low-cost option for heating.

- The infrared electromagnetic waves have a range from 780 nm to 10 microns.

- Short wavelength has high frequency and energy. The infrared heating produces temperatures up to 6,512°F (3,600°C).

- Now infrared heaters are used in homes, offices, and other buildings since they have good heating features.

- They are also part of the medical industry.

Elements of infrared heaters

- A commonly used filament material is tungsten wire for electrical infrared heaters that are in coil form and make a high surface area.

- Some low-temperature materials are used as replacements for tungsten, such as carbon, iron alloy, and aluminum.

- Carbon filaments are fickle to make since they heat up faster as compared to medium-weave heaters configured with FeCrAl filaments.

- For unfavorable light conditions, ceramic infrared radiant heaters are used.

- that comes with 8 meters of alloy resistance wire in coil form that releases heat over the complete surface area of the heater, and the ceramic has 90 percent of the radiation absorption features

- Absorption and emission are according to the physical dimension of the object, so ceramic is good to use.

- Industrial infrared heaters also use a gold coating on a quartz tube that reflects infrared radiation and sends it towards the heated medium.

- Infrared radiation colliding on the medium becomes doubled. Gold provides good oxidation resistance and has high infrared reflection, about 95%.

Infrared heaters working

-

- The infrared heating system comes with two main parts: a heating component that is made with tungsten and quartz and transforms electrical energy into thermal energy, and a reflector that reflects the infrared signal to the targeted material.

- This feature helps to design portable and fixed infrared heaters that provide constant and reliable heating.

- A reflector is used to define the working efficiency of an infrared heater, and a reflector that has high reflectivity provides high transmission of radiant heat, minimizes heat losses, and reduces energy wastage.

- The accurate design, surface finishes, and materials used help to accurately focus infrared waves in an outward direction and provide maximum coverage of material.

- The reflector needed to have features like resistance to corrosion and work in high-temperature conditions and also be reliable.

- The basic materials used for reflectors are aluminum, stainless steel, and quartz that have good resistance to heat, low weight design, and reflection features.

- Some modules use gold coatings that provide good reflection features and focus heat at a given point.

- Before using infrared heaters, find some features such as watts, types, mounting features, safety features, and whether it supports smart controls.

different industrial infrared heaters

Industrial infrared heaters come in three basic types: ceramic, quartz, and metal sheathed. These types are made for generating electromagnetic infrared radiation for heating purposes, and their temperature range is 1300°F to 1600°F. and, while metal-sheathed comes with high-temperature conditions.

Quartz Infrared Heaters:

- Quartz infrared heaters release short-wavelength infrared energy that produces intense heat that is high temperature to use in industries.

- It is good to use for high-temperature manufacturing processes like glass production, paint curing, and plastic thermoforming, and it is low to use for general-purpose applications since it has focused radiation.

Ceramic Infrared Heaters:

- Ceramic infrared heaters are low cost and reliable for focusing on the manufacturing area. The medium wavelength is used for drying, curing, and heating different materials like plastic and textiles.

Metal-Sheathed Infrared Heaters:

- Metal-sheathed infrared heaters have a good durable nature and are used for submersible heating projects. It has features to handle 2000°F and work well in the laboratory and industries.

Which to choose for applications

- For using an industrial infrared heater, it is best to find the energy efficiency wavelength for certain materials.

- Safety features and maintenance required. With the use of accurate infrared heating methods, we can provide good quality and reduce manufacturing expenses and get high-speed production.

Features of Infrared Heating

- An infrared heater is energy efficient, and it warms objects. These heaters do not lose heat since they do not have waste heat at the time of transferring to the medium.

- Infrared heaters heat instantly, and radiant heaters produce heat directly to heat surrounding objects, like convection heaters. So it is used for drying applications.

- Infrared heaters also provide natural heat. This heat provided with unrated heaters is like radiant heat that you get from the sun. The infrared heater generated heat that did not increase the level of humidity or deplete oxygen from the surroundings and did not evaporate moisture.

- Infrared heaters also reduce the creation of molds and mildew. Infrared heaters also control moisture and the creation of microbes. That feature also reduces stuffy noses and itchy eyes and skin.

- Their working is noise-free since they do not have a fan for heat circulation.

- Electric infrared heaters are also environmentally friendly. Electric infrared heaters do not generate gaseous materials or toxic fumes.

types of infrared heaters

Electric Infrared Heaters

- Electric infrared heaters use current for heat transmission. The heating system generated heat with the use of Joule heating. Joule heating is the transformation of electrical energy into heat through current flow to an element with high resistance. The resistance of the heating element should be less than that of the insulators. the common heating component materials are tungsten, nichrome, cupronickel

Radiant Gas Heaters

- This type of heater, also called a gas-fired infrared heater, is based on chemical energy stored in propane or petroleum as a source of heat. It uses a heating component that transforms the heat energy of gas flames into infrared electromagnetic radiation. The heating component and combustion chamber come in metal, ceramic, or glass coverings. Radiant gas heaters also have some subtypes.

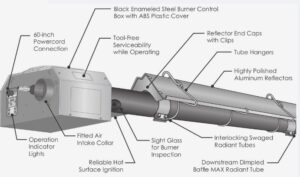

Radiant Tube Infrared Heaters

-

- These heaters come with a gas-air mixture combusted in a long steel tube that heats in range of 800 to 1472°F and releases infrared radiation. It is a common heating module since it occurs at a given point.

Luminous Infrared Heaters

-

- This heater has gas air mixture applied through a porous matrix of refractory materials that ignites and heats the surface over a temperature value 1350°F. high heat radiant released and directed at the required point for this heater

types of Infrared heaters based on the wavelength of the infrared radiation

Near-Infrared (NIR) Heaters

- NIR heaters generated infrared with a range of 0.78-1.5 microns in wavelength with a temperature range of 2,600-4,712°F (1,300-2,600°C). This wave comes with high frequency and is highly transmissive and reflective with low absorption. As a result, it is low in effectiveness and not good to use for drying applications.

- It generated high-strength heat that can easily be felt about 3 to 4 meters from the emitting point and does not produce constant heat.

Medium-Wave Infrared Heaters

- MWIR heaters produce 1.5 to 3 micron infrared waves, and the temperature range is 1,300-2,372°F (500-1,300°C); it is a low frequency range that is absorbed in materials without affecting features. It is part of industries such as drying and curing paints, plastic foils, and sheets.

Long-Wave Infrared Heaters

- FIR heaters generate infrared waves with 3 to 1000 microns wavelength and work at low temperatures. These low wave frequnecy easy to absorbed in material. Water also absorbs infrared heat for this range. Heat generated through FIR heaters is also absorbed in our skin and passes through tissues, blood, and other parts of the body.

- It takes a longer time, about five minutes, for warming the surrounding area and part of the saunas, incubators

Types of infrared heaters based on construction

Quartz Heat Lamps

- Quartz heat lamps were first made in the 1950s by General Electric. It produces heat with a temperature more than 2750°F and releases medium to short infrared waves.

- It can easily heat neighboring bodies. Quartz used as enclosing material protects the tungsten heating element that has features to handle high temperatures as compared to glass.

- It is filled with high-pressure inert gas having halogens, gaseous bromine, or iodine that regenerates tungsten atoms in the filament and increases the working life of the heating element.

Carbon Infrared Heaters

- Carbon infrared heaters come with woven carbon fiber heating elements that are configured in quartz. It also has halogen gas, as a quartz heater has. It operated with 2912F and released medium infrared waves.

- Carbon fiber generates gentler heat, and light has low intensity as compared to tungsten.

Ceramic Heaters

- Ceramic heaters come with a heating element that is configured into ceramic material. The working temperature range is 149 to 371°C, and it releases medium to long infrared waves having a 2 to 10 micron wavelength.

- Ceramic castings are in different designs; a flat-shaped cast applies infrared heat on a larger area, and a concave shape focuses infrared heat on one point.

- For avoiding corrosion, the surface is glazed.

- Ceramic heaters are part of comfort heating and industrial processes like paint drying, curing, annealing, and packaging. Food processing industries and the medical industry also use ceramic heaters.

FAQs

What is a key feature of infrared heaters?

- The main feature is that it uses electromagnetic waves in the infrared wave range. They have features for energy transportation and are not seen with the human eye. infrared heating energy transfer feature used for heat transfer.

What are the different types of infrared heaters?

- infrared space heater

- infrared patio heater

- portable construction infrared heater

- Electric Infrared Heaters.

What is the distance between infrared lights?

- Through infrared light therapy, the high distance is 40 cm. Infrared light passes deeply into skin and works for muscles, joints, and tissues. Distance helps light to pass deeply without any damage.