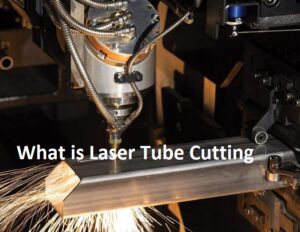

Tube laser cutting is important for manufacturing and metalworking; it is used for a precise and highly effective process. The knowledge of tube laser cutting is important for optimization of the manufacturing process and business growth. In this post we will cover details and features for laser tube cutting with its limitations and uses.

What Is Laser Tube Cutting?

- Laser tube cutting is a technique and process that is used for cutting tubes, channels, and structural designs.

- In this process, structures are cut to a certain value of length. It also has features for cutting holes in tubing.

- It is the correct process for cutting designs. It is also used for different materials in sizes and shapes.

- To get service for laser tube cutting, use the services of a famous and experienced laser cutting services provider.

- Tube laser cutting is basically a machining process that is used for cutting tubes for different layouts at a certain length and making laser designs on tubes.

- It is a high-speed and accurate process compared to manually drilling holes.

Tube Laser Cutting is working.

- In this process tube is positioned at 90 degrees on the laser head, where the cutting end is down from the rotating chuck. The chuck is a rotating clamp that grips the tube and rotates when required. Tube rotation is an easy process compared to laser head moving in a circular motion of the tube.

- A laser makes a connection with the tube surface and cuts the material over a defined path.

- The tube is rotated with the chuck, and the motor at the back pushes forward when required. Mostly, a tube laser cutter comes with 3-axis motion. Lasers normally move up and down, and the tube rotates and moves front and back.

Types of Laser Cutting Machines

UV Machine

- This machine employs ultraviolet light for cutting materials like ceramic and glass. It is used in solar energy and electronic devices.

Fiber Machine

- Fiber laser cutting is the latest machine used for the manufacturing process since it has high efficiency and accuracy. Laser tube cutting machines work based on diode banks that are compactly structured and produce a laser.

- The types of diodes and structure help the laser to generate linearly and conserve energy.

- Compared to conventional CO₂ lasers, fiber lasers provide high wall plug efficiency with low use of energy.

CO₂ Machine

- CO2 laser cutter is lower in features than fiber laser but is still used for different industries. This machine comes with gases and a current mixture for producing a laser beam. The production of lasers in CO₂ machines is a complicated process. When current is given to a mixture of gases, a laser beam whose intensity increases with mirrors.

- CO₂ uses more energy but uses a complex process for beam production.

Nd:YAG Machine

- This machine operated with the use of crystal for cutting metals, ceramics, and plastics. It is normally used in the dental and medical industries for high accuracy.

Galvo Machine

- This machine uses a laser beam to make materials such as metals and ceramics. It is commonly used for the aviation industry, vehicle parts, and electronic devices.

Materials for Laser Tube Cutting

Stainless Steel

- Stainless steel is a commonly used material for different industries due to its reliable nature. It has resistance to corrosion, rusting, and staining, so it’s best to use it for different projects. It is nonmagnetic and has ductile features.

Aluminum

- Aluminum is also a common material that is used in manufacturing industries commonly. It is low weight and has resistance to corrosion and is best for different industries where low-weight products are needed.

- Pure aluminum has good resistance and conductivity. Aluminum alloy used since has high strength and is part of the vehicle industry.

Titanium

- Titanium is used for the aviation industry and medical instruments. It is high strength, lightweight, and resistant to corrosion and handles different conditions.

- Pure titanium is used due to its good resistance to corrosion, and titanium alloy has high strength and handles high temperatures.

Brass

- Brass is an alloy of zinc and copper that used since its malleable nature. It resists corrosion and has acoustic features that help to use musical devices and also parts of industrial circuits.

Copper

- It is conductive metal and has good electrical features. It has good thermal features with resistance to bacterial growth in medical devices.

Features of Tube Laser Cutting

Speed

- This process has features to perform different processes with automation, with less time, and provides high-speed lead time.

Accuracy

- It is a highly accurate process and is used for complex part creation. For cutting complicated components into tubes coping process was used that performed with a machine that can cut at any angle.

- Tube laser cutting machine: we can cut at different designs and shapes, like circular, square, etc.

High Efficiency

- Tube laser cutters provide high efficiency for cutting different projects, such as tabbing operations for welder location marking. Pre-cutting holes in structural tubing also makes the process fast.

Flexibility

- • A tube laser cutter cuts bends in tubes to provide larger motion options.

Zero Material Waste

- Any error at the time of cutting can cause damage to the complete tube design and waste of materials. But laser cutting does not waste material since it is a low-error process.

- Low material waste and high cutting speed provide high output.

Zero Tool Wear

- Mechanical tube-cutting techniques like electric saws and hydraulic blades get damaged after rubbing on working components. Laser tube cutting does not have tool wear since it is a non-contact process.

Laser Beams for Tube Cutting

Two main types of tube laser cutting are explained here.

Fiber Lasers

- Fiber laser technology operates with the use of compact diodes for emitting light into an optic fiber for amplification of light. Fiber lasers are smaller than CO2. Fiber laser systems come with high energy efficiency and transform current from the wall into laser heat.

- • The fiber laser cutter comes with a small beam diameter, providing high accuracy and penetration with accuracy maintenance.

CO2 Laser Beams

- CO₂ lasers are produced with the use of a large gas-filled chamber having high current. This structure of gas lasers provides high-power laser beams with the use of high current.

- Gas laser is a low-cost process used for small industries. The glass chamber is a small working life process that has a high maintenance cost.

Advantages of laser tube cutting

- It provides cutting features with high accuracy.

- It has repetition of design with accurate points.

- Flexible laser cutter operated for different materials like metals, plastics,s, and wood.

- • The laser cutting process is effective and provides high production. It reduces use of materials and optimizes output.

- It uses low process after laser cutting since edges do not have burrs and no finishing is needed like other processes.

Tube Laser Applications

Aerospace

- The aviation industry uses the tube-cutting process for the oxygen and fuel delivery system.

Furniture Industry

- Wood tubes are used for furniture production, with metallic tubes for furniture legs.

Sports Industry

- Different sports instruments made with metallic tubes and pipes for providing structural support. Laser tube cutting is used for making bike frames, hockey sticks, etc.

Construction Industry

- Tube laser cutting machines are part of processing round and square metallic tubes. The construction industry also employs this machine for cutting designs in different shapes like angle bars and U-channels.

Electronic Devices

- • The tube laser cutting process is is also used for the copper and aluminum cooling system of electrons. Heat sinks used for computers needed accurate cutting tubes for heat transfer with holes.

Safety Measures for Laser Tube Cutting

- For performing laser tube cutting, use protective goggles for protection from laser flashes.

- Make sure that the working area is ventilated for managing harmful fumes.

- To avoid any issues, set emergency stop buttons and do not leave the machine in working condition for any damage.

cutting tolerances for tube laser

- The accurate laser tube cutting is an important feature. normally cutting tolerance in the range of 0.1mm to 0.3mm. The width of the cut is in the range of 0.2mm to 0.5mm with low material wastage.

- laser tube cutting machines Cut tubes about 25.4mm thick. The accurate thickness can be based on machine power and material.

Factors for tube laser cutting

Material

- Make sure that you use material of high quality and that you handle the laser cutting process.

Machine Check:

- • The machine is working in the proper way and also has good maintenance.

Safety Gear:

- There is a need to have required safety gear like gloves and goggles.

Design

- Confirm that the design does not have any errors for proper laser cutting.

Is laser cutting tubes a costly process?

Read more:How To Gap Spark Plugs? Process, Features, Working

- Cost for laser cutting tubes is based on material, design complexity, and labor cost. Normally, the cost for laser tube cutting is in the range of $100 to $700 and can be higher.

How much expensive laser tube cutter ?

- Laser tube cutters are in different models and features. The simple cutter costs $10,000, and the latest machines are more than $500,000.

How fast can a laser cutter cut tube?

- Laser cutters are high-speed modules. That can provide a cutting speed of about 500 inches per minute on a tube. But real speed can differ according to thickness and design complexity.

FAQs

How much laser tube cutting is a precise process?

- Laser tube cutting provides high accuracy. Now, the latest machines used that are highly accurate come with tolerances of +/- 0.005 inches, so it’s best to use them for complicated designs and high-precision applications.

Which one is betterCO2 or fiber laser?

- CO₂ and fiber lasers are good, but CO₂ is versatile and uses more energy and comes with complicated modules providing power losses.

- Fiber lasers are effective and need low maintenance with wall plug features. It is good at cutting reflective materials and provides higher speed features than CO₂ lasers for some metallic thicknesses.