The leaf spring is an older but simple type of spring that is used in vehicles, especially for motorsports. It is an iron length that is connected with the chassis, and each end is connected with the axle in the middle. It is stacked with different thicknesses for tapering for finding spring rate, and for providing high spring rate, a larger number of blades is stacked on top of each other. In this post we will cover details for leaf springs and related factors.

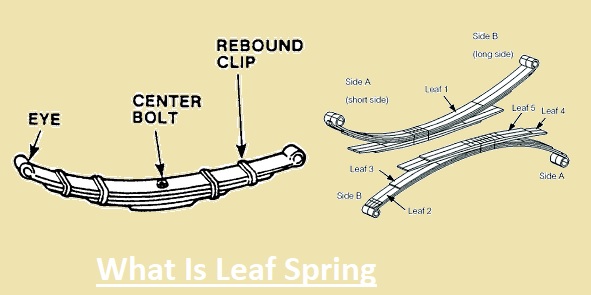

What is a leaf spring?

- The leaf spring is a basic spring type that is used in wheeled vehicles for providing suspension. It is also known as a carriage spring and a semi-elliptical spring.

- It is an older type of vehicle suspension. The leaf spring is made of arc-shaped thin plates that are connected with the axle and chassis to help the leaf spring flex at 90 degrees for road surface irregularities.

- A lateral leaf spring is used for running the length of the vehicle and configured at 90 degrees to the wheel axle

- Leaf springs are used for providing different functions like springing, locations, and also damping processes through interleaf friction.

- but this friction becomes controlled, which causes irregular suspension motions, and for this purpose mono-leaf springs are use

Leaf Spring Suspension Working

- The leaf spring comes with different leaves that are known as blades. The blades come in different lengths.

- The longer blades come with eyes on the end sides. That blade is known as the master leaf. Its blades are connected with the use of steel straps.

- the U-bolt handle spring on the axle, front or back side. One end side of the spring is configured on the frame through a simple pin, and the other end is connected with a shackle.

- If a vehicle faces a projection on the road, the wheel moves up and deflects the spring. that varies the length between spring eyes, and if both ends are fixed, the spring does not have the features to handle these changes.

- It gets through using a shackle at one end that makes a flexible point. If the shackle gets compressed, the leaf increases the features for the spring and makes soft springiness.

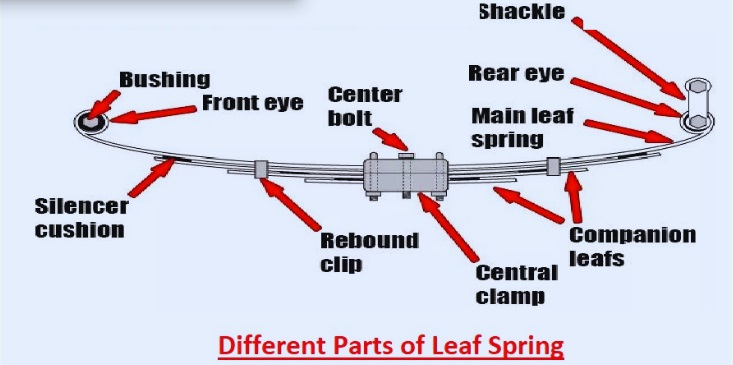

Different Parts of Leaf Spring

Metal Plates

- The leaf spring comes with different metallic plates called leaflets that are configured in layers on top of each other to reduce size. These leaves are known as camber, which makes a semi-elliptic structure.

Master Leaf

- A longer-sized leaf exists at the upper part of the spring that is called the master leaf. It has a curved shape at both ends for making a spring eye. For connecting the leaf spring with the vehicle structure, two bolts pass through the master leaf eyes.

Center Bolt

- The middle or center bolt of the leaf spring is used for providing structural quality. The center bolt is the main part that lies in the middle of each leaf in the hole. Its working is to hold other leaves. It has U-bolts and middle bolts that strongly hold all leaves.

U-bolt

- The U-bolt gives force for a strong connection of the leaf spring and related parts. The other parts are the top plate, axle seat, and lower plate.

Rebound Clip

- This component makes accurate alignment of leaves and avoids lateral shifting of leaves when the vehicle moves. In the middle, the leaf spring provides support for the axle. It is a steel band that comes with a fixed position on eithera side of the middle bolt.

Spring Eye

- These are loops that exist at the end of the leaf spring. They are strongly fastened with chassis through use of shackles.

Shackle

- The leaf spring is connected with the frame at both ends, normally the front and the other connected through a shackle. Due to shackle compression, the leaf gets high spring features and makes soft springiness.

Rubber Bush

- leaf spring bushing used on front eyes of spring and wrapped in steel or rubber.

Installation process of leaf springs

Preparation

- First of all, for installing the leaf spring, make ready the older suspension. It is suggested to prepare3 days before removing the older spring.

- Older leaves can be rusted, so remove them without any damage to other parts. For preparing old suspension, soak all components to make them loose, and it helps to provide easy removal.

Raise Vehicle

- Now raise the back side of your car and remove the back tires. Use a floor jack for this purpose until the tires are 3 inches above the ground.

- Put the jack stand on any side of the car about one foot in front of the back tire. After that, lower the floor jack and support the rear axle by putting it beneath the back axle gear.

Disconnect Springs

- Now remove the old leaf spring; loosen the prepared nuts and bolts, but the U-bolt first on the bracket. Before removing the U-bolt, do this. After that, remove the leaf spring by removing the eyelet bolts from the bushes. Old leaf springs can be lowered easily.

Connect Eye Bolts

- After removing older roofing, connect new. Put the leaf spring in configuration and use eye bolts and retainer nuts for each side for a strong connection of the spring with the hanger. It is best to use new nuts and bolts.

Connect U-Bolts

- Strongly connect all mounting bolts and put U-bolt brakes over the leaf spring back axle. Check that it is strongly connected at the position and all bolts are tightened accurately. It is referred to check the tightness after some days of connection for avoiding any loose features.

Lower Vehicle

- Now remove the floor jack and lower your car or other vehicle to the ground, not your work done.

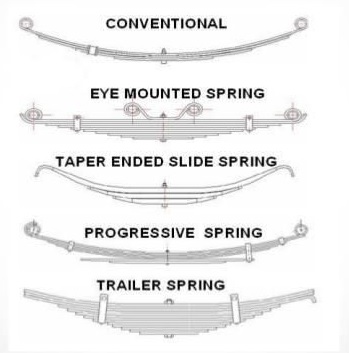

Types of Leaf Spring

Elliptical Leaf Springs

- Elliptical leaf springs are in different shapes, like three-quarters, half-full, and quarter designs. Semi-elliptical springs are used for trucks. These springs are of parabolic design and exist at the front and back axles of trucks and, for cars, exist on back axles.

- Older models of vehicles use quarter elliptical leaf springs. It is like a semi-elliptical spring. The combination of an elliptical nib with a semi-elliptical nib makes three-quarter nibs.

Transverse Leaf Spring

- Transverse leaf springs come with the same design as semi-elliptical ones have. but these springs are easily configured below the truck with the base of the curve directed toward the chassis. This leaf spring type comes with different locations as compared to semi-elliptical types.

- This installation occurs on the side of vehicles rather than on the front or rear axle. Lateral leaf springs are not commonly used on trucks.

Platform Leaf Spring

- This type of leaf spring uses semi-elliptical leaf spring pairs; one is downward When connected with a vehicle, the spring is compatible for 3 locations of vehicle weight over each side.

Multi-Leaf Springs

- Panels are put on top of each other and connected, making it easy for vehicles to carry high weight loads.

- the use of multi-leaf springs; the plate size becomes small. The panels are based on the length of the layers; the long component is made through grommets.

- Multi-leaf springs are common types of leaf springs to use in low-weight vehicles and high-weight vehicles. They are in a stacked format that shows feathers are thick in the middle, which is called a semi-elliptical look.

Mono Leaf Springs

- Mono leaf springs are good to use for LCV but not for trucks since they do not have heavy vehicle features. It is thick in the center point and becomes thin moving toward the ends and has the same design as a multi-leaf but does not have extra plates.

Leaf Spring Characteristics

- The 2 ends of the leaf spring are made in round eyes where fasteners connecteach end of the spring with the vehicle frame.

- Some springs come with a concave end that is called a spoon end for carrying swiveling parts.

- One eye is fixed to that pivot with the motion of a spring, and the other eye is connected with a hinge system that helps make the end pivot and limit motion.

- The leaf spring is connected with the frame at both eyes at one end, normally the front side, and the other end is connected through a shackle that is a short swinging arm.

- The shackle gets features of a leaf spring for elongation in compressed form and provides soft suspension.

- The shackle provided some flexibility for the leaf spring so it was not damaged when facing high loads.

- The axle is connected with the middle of the spring through the use of U-bolts.

- Leaf springs work as linkages for holding axles at certain points, and separate linkages are not needed.

- In result, suspension makes strong and easy assembly. Interleaffriction reduces and controls spring motion and also rebound until shock absorbers are used and has a higher benefit than helical springs working.

Leaf springs vs shock absorbers

- Leaf spring transfers force in 3 dimensions and absorbs energy through braking and acceleration processes.

- The main function of this spring is to manage the weight of the vehicle and provide proper springing with wheel guidance and replace control arms.

- Leaf springs provide damping factors, but it is not their main working; that is a byproduct due to multi-layered construction.

- In case of suspension flexes, friction occurs between individual leaves and absorbs shocks passing through wheels. This frictional damping minimizes riding comfort, making the vehicle sensitive to irregularities on the road.

- The rigid design of the leaf spring flexible sling working, which varies the distance between the bushing and shackle at the time of motion, provides these factors.

- So shock absorbers are used for damping. Their control of each wheel independently was made for absorbing energy from wheels moving on the road.

Factor for choosing the right leaf spring

- Follow these points before selection of leaf springs for your vehicles.

Width:

- The dimensions at the lower end of the spring leaves are related to the width of the spring seats.

Free Length:

- The spring length from eye to eye needed accurate measurement.

of Leaves:

- Count the number of strips of steel stacked with each other and count at the middle point.

Flat Length:

- The length value that is for the real contour of the spring is measured as compared to the free length measurement since the old spring relaxes when used. Flat length is measured by getting the length from the middle of one eye to the middle bolt on the spring, which exists on the other side, and then adding them together.

Eye Size:

- The eye size is important for making a trailer and for choosing other parts that are bolted with a spring.

Leaf Spring Limitations

- The basic disadvantage of a leaf spring is that it is not good for suspension tuning. For racing purposes and car uses, it is required to change the suspension design for driving conditions and for different driving methods that are easy to adjust coils.

- Their installation is difficult and does not provide good comfort for driving since interleaf friction exists between leaves.

- With time, springs become loose and their shape changes and causes sag. This sag varies the vehicle weight which also affects handling features. It also affects the axle-to-mount angle.