A pinch valve is a 2/2-way valve that employs or stops abrasive, granular, corrosive materials. It operates properly by using compressed air to open and close the valve.

It operated through using compressed air for opening and closing the valve. In open condition, it provides a continuous flow path for easily handling different medium flows through low resistance. In this post we will cover detailed features of pinch valve working and related factors. So let’s get started.

What is a pinch valve?

- A pinch valve is a complete bore or fully ported control valve with a pinching effect for controlling fluid movement.

- A pinch valve is a 2/2-way valve that allows or prevents fluid in different media, such as granular and corrosive media.

- For an open condition valve not to restrict flow and provide different medium movement through the bore.

- A flexible internal rubber sleeve exists that separates from the remaining part of the valve to avoid contamination and damage to the valve from other parts.

- pinch valve is used of applications such as granular materials, slurries, gravel, textile fiber, powder, pellets, and glass

- This low-cost valve provides reliable and easy operation in different industrial applications.

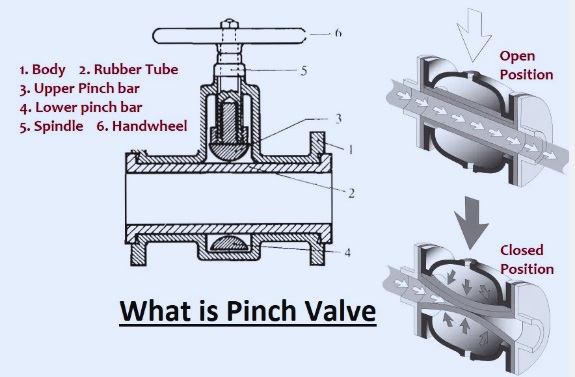

Pinch Valves Working

- • The pinch valve has bidirectional on/off with almost zero leakage. Since the tube features self-clearing flaring movement, it controls scaling deposition through forming, and the pinch valve does not jam.

- Flexible rubber sleeve compressed for controlling fluid movement.

- When the valve opens, the sleeve in its normal posture helps fluid move easily.

- Closing valve through different processes, like actuator, manual, or pneumatic pinch sleeve externally.

- When the sleeve is squeezed, it presses the inside control flow completely.

- When the pinch is released, flexible sleeves shift back to their real condition, helping fluid flow.

- The main factor here is that the fluid does not make a connection with the valve body, but the internal sleeve does, which is good for handling sterile fluids.

Types Of Pinch Valves

Pinch valves have different types and are used for different materials and based on features. The basic types are open-body pinch valve, enclosed-body pinch valve, and pneumatic valve.

The open body pinch valve is good to use for low-pressure applications and has simple maintenance.

The enclosed body pinch valve protects well from outer components and is good for harsh conditions.

Pneumatic pinch valves employ air pressure to regulate flow and are part of an automated system where abrasive fluids work.

Manual Pinch Valves

Manual pinch valve control is done manually with the hand and used for low-pressure applications. This valve has a housing structure that is a flexible elastomeric tube where fluids flow.

The mechanical actuator is a handwheel. If we turned the handwheel or pulled the lever, the bar pushes downward and compresses the sleeve.

This pinches closed the path for flow and restricts flow. For flowing fluid, we can pull back the lever in the reverse direction.

The manual pinch valve is simple in design and low in cost. It is good for using an abrasive fluid medium, since the part makes a connection with the moving fluid in the internal sleeve.

It can be easily maintained, and the inner sleeve can be replaced frequently.

Pneumatic (Air-Operated) Pinch Valves

Air-operated pinch valves configure larger automated replacements than manually controlled pinch valves.

The structure is like a manual pinch valve that comes with a flexible rubber sleeve internally, then a manual working lever, and handwheels. This valve compresses air to regulate sleeve movement.

If air pressure does not exist, the sleeve is in open conditions where the fluid medium moves, and flow is controlled when compressed air is applied and the neighboring sleeve presses inside.

How to Choose a Pinch Valve

Different factors help in the selection of pinch valves that are

Material:

- Use a valve body made with a material that has low weight for easy connection and handling. as the medium does not make a connection with the valve body. Sleeve material is important because it is directly connected with fluid.

- Commonly used materials for sleeves are natural rubber, silicon, and food-grade rubber.

- • The sleeve needed to have good resistance to abrasion for handling damage due to different fluids and conditions.

Pressure

for accurate working pressure differentials properly monitored

Opening condition:

- Medium pressure is needed to cross control pressure. If the difference is low, the valve does not work well. At the time of opening, control pressure is zero bar.

Closing condition

- • The control pressure needed to be larger than the system’s pressure. Ineffective pressure difference affects the valve closing process.

Pinch Valve Advantages

pinch valve comes with different benefits like

- It is preferred for corrosive and abrasive materials, providing a flow path and no clogging through the medium.

- It has low friction and turbulence.

- It saves the medium from contamination and easily replaces rubber sleeves with less required maintenance.

- It also provides good sealing features with fast opening and closing, and uses low energy.

Disadvantages

It has some advantages, like

- The elastomeric features of the pinch valve sleeve are not used for high-temperature conditions.

- high pressure differential resulting from the rubber sleeve for reshaping, which causes the valve not to open completely

- This valve is not used for vacuum applications since suction causes the sleeve to be damaged.

Pinch Valve vs. Conventional Valves

Some valves that are conventional valves come in different types, like butterfly, ball, and diaphragm valves.But the pinch valve is a new type of valve.

but pinch valves are reliable, low cost, and easy to use for different applications.

Pinch valves do not come with extra components that need to be replaced often, like rings, seals, and packing.

Applications of pinch valves

The uses of pinch valves are as

- Sanitary pinch valve comes with rubber sleeves created with nitrile, a natural rubber that is FDA approved for contact with food. Pinch valves cycle speedily, providing high packaging efficiency.

- It is also used for the pharmaceutical industry, where cleanliness is important so sanitary pinch valves are preferred.

- The chemical industry comes with larger uses. Pinch valves easily handle different applications since different materials are used for pinch valve sleeve construction.

- The natural rubber pinch valve has a longer working life and easily handles abrasion of cement.

- The pinch valve has abrasive resistance for handling solids and bulky materials. The valve’s full-bore opening controls solids through the valve, preventing clogging.

- Pinch valves through reinforced rubber sleeves easily control the high-abrasiveness features of a ceramic flow.

- This valve is also preferred for moving plastic pellets and nibs that can clog the valve.

- This valve also works as a pressure relief and off valve in the wastewater industry.

FAQs

Define a pinch valve.

- pinch valve control flow device employs a flexible tube and compressed air for opening and closing the fluid path. That is good for handling corrosive and abrasive fluids.

What is the difference between a pinch valve and a needle valve?

- Pinch valves regulate flow through pinching of a flexible sleeve and are used for slurry media and bulky materials.

- Needle valve uses a narrow plunger for accurate regulation flow at small applications

What are the uses of a pinch valve adapter?

- Pinch valve adapter used for connection valve for supporting piping, providing a leakage-free connection. that helps for proper alignment and is compatible with a flexible sleeve when working.

What is the difference between a plug valve and a pinch valve?

- The plug valve employs a conical plug for stopping and providing flow, which makes it good for high-pressure operations.

- A pinch valve uses a flexible sleeve pinched off for less pressure and abrasive fluid movement.