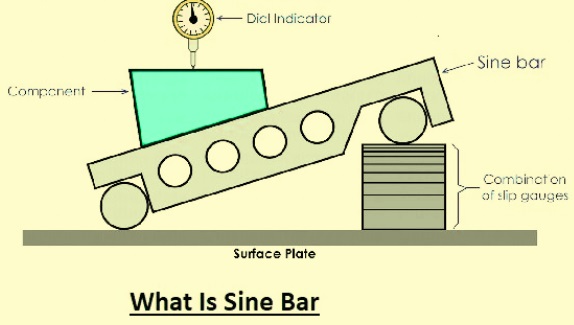

The sine bar, also called the precession angle device, is a certain type of instrument used for accurate measurement in the field of machining and metrology. It is used for measuring and making angles at the accurate level and with high accuracy. For providing proper alignment and machining of working components at a certain angle, they are part of quality control labs and the manufacturing industry. Here we will cover the details and different features of the sine bar. Let’s get started.

What is a sine bar?

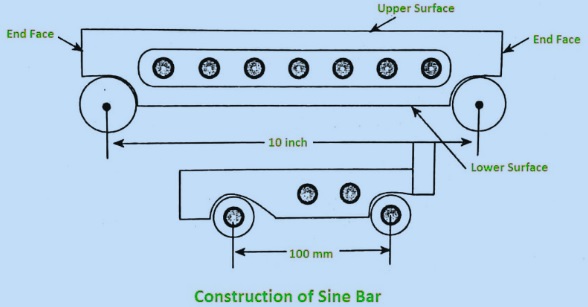

- The sine bar comes with a hard, accurate ground structure with two accurate ground cylinders configured at end points. The distance between the cylinders’ centers is properly controlled, and the upper part of the bar is parallel to a line through the two rollers’ centers.

- The dimensions between the two rollers are selected as whole numbers and make the design like the hypotenuse of a triangle.

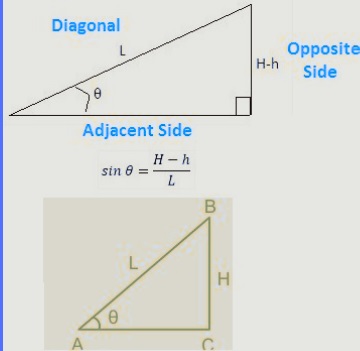

- If the sine bar is set on an accurate level, the upper edge is parallel with the surface. If one roller is raised in result of a known distance value, with the use of gauge blocks, the upper edge of the bar is tilted through the same value and makes an angle that is measured with the use of the sine rule.

- • The hypotenuse shows constant dimension values, that is, 10mm or 10 inches.

- The height is measured from the dimension between the bottom of one roller and the table surface.

- Angle measured through sine bar. Some metalworking reference books come with tables that show dimensions used for getting angles in the range of zero to 90 degrees that are increased with one-minute intervals.

sin(angle)= perpendicular/hypotenuse.

Sine Bar Construction

- The sine bar is made with the use of a rigid steel gauge body that comes in two identical sizes, with their axes aligned to each other in a parallel configuration.

- The upper steel bar is parallel to the line, makes a connection with roller centers, and the sine bar length is configured according to the distance between roller centers, and the length is set in the range of 100mm, 200 mm, or 300mm.

- For minimizing weight, holes that are called relief holes are made. A sine bar does not measure angle in an accurate way if used alone but does if used in combination with slip gauges and elevation gauges.

Surface Plate

- The sine bar and other components are configured on surface plates that provide an accurate horizontal reference area for the bar. There is a need to set the upper part of the sine bar parallel with the horizontal planes of the surface plate for accurate alignment.

Dial Gauge

- To make sure that the surface is parallel with the base, use a dial gauge that provides a uniform surface. It measured zero deflection at the time of traversal. A dial gauge is the main component of sine bar measurement that measures the angle of the tapered sine and checks that the working component’s upper surface accurately aligns with the surface plate.

Block Gauges or Slip Gauges

- The accuracy for sine bar connection becomes strong with the use of a block gauge, also called a slip gauge, that works as a standard for length and height measuring values.

Vernier Height Gauge

- For measuring the sine bar roller height vernier height gague used that helps to easily measure angle of larger components of structures.

How Sine Bar Works?

- The working of the sine bar is based on trigonometry’s fundamental principles.

- If one roller of the sine bar is set on a surface plate, and the other is configured at a height of slip gauge, that makes a triangle that comes with the sine bar, the surface plate, and the slip gauge.

- • The hypotenuse of the triangle is related to the sine bar, which is made with vertical clip gauges and a surface plate base.

- Slip gauge height is denoted with H and sine bar length L in the below image; the sine ratio is defined

H/angle L θ

- The angle θ is measured with the measuring inverse sine of H/L that provides angle values.

Sine θ = H/L = BC/AB

Types of Sine Bar

- The basic type comes with a lapped steel bar on each end cylinder, connected cylinders’ axes parallel with each other and also parallel with the upper surface of the bar. In some types, holes are drilled in the structure of the bar to reduce weight and ensure accurate handling.

Sine center

- It is the main type of sine bar that is used for conical objects with male and female components. Its angle measuring range is up to 60 degrees.

Sine table

- • A sine table is a larger and wider type of sine bar that comes with a locking system at a position used for holding working components at the time of working.

Compound sine table

- It is used for measuring the compound angle of larger components. Where two sine tables are configured on each other at 90 degrees. Table twit for a certain configuration.

Sine Bar and Protractor

- The sine bar is used for measuring angles according to trigonometric rules with high accuracy. A protractor helps to measure angular values with low accuracy and uses a circular scale for measuring values.

Sine Bar

- It is used for measuring the accurate value of angles. It has a rigid steel gauge casing with two rollers.

- It provides high accuracy for angle calculation.

- It is used for measuring angles with a combination of slip gauges and elevation gauges.

- Its values are limited for certain angles with lengths. It is used for providing accurate angle setups in machining.

- It was also part of certain types of operations that needed accurate angular measurements.

- Its main uses are in engineering and machining systems.

Protractor

- Its uses are in different configurations for measuring angles, and its structure comes with a flat, semicircular tool with degree markings.

- It has lower accuracy than a sine bar and is used without any other tools for measuring angle values.

- It has features for measuring 360 degrees, measuring angles, and being used in different fields for angle measuring.

- It is also part of carpentry and construction and is also used for general angle measurements.

Advantages of Sine Bar

- Sine bar is a highly accurate angle-measuring tool and provides good matching output measurements.

- It provides constant angle measurement values and matching results. It also measures angles at different ranges and versatile option for machining operations.

- It is easy to use tools and does not require any special skills.

- It is a low-cost option for angle measurement and the machining process.

Disadvantages of Sine Bar

- It is used for limited angle measuring lengths.

- It needed some more tools, such as slip gauges, for accurate results.

- It is not used for small or larger angle measurements.

- It has chances for wear and damage that affect accuracy.

- It is more complicated than protractors.

Sine Bar Applications

- It is used for setting and finding the angle of working components.

- It helps to check values of angles in working components.

- Some types of sine bars are used for configuration of components in conical-shaped machining processes.

- It is used for measuring angles and also for high-weight components. It also measures the flatness of the surface and also checks the angle of the taper key.

FAQs

What are these of a sine bar?

- Sine bar used for measuring angle at acute point of working component. It is made with high-chromium, corrosion-resistant steel, and it is hard-designed and precisely ground. It comes with two cylinders with the same diameter at the end of the bar.

What are the features and limitations of a sine bar?

- The sine bar is employed in combination with a slip gauge block for accurate angle calculation. The sine bar used for measuring angles is an accurate way of working with components.

- Its disadvantages are that it measures certain angles according to length and also uses more tools, such as a slip gauge, for measurements. It’s not good for measuring small or large angles.

- It also gets damaged and reduces accuracy.

Are a sine bar and a sine table?

- The sine bar is an exact angle-measuring tool, and the sine plate supports the component of a fixture at an angle. The sine plate is accurately ground and comes with two cylinders.

Why does a sine bar have holes?

- The upper part of the steel bar works parallel with the connection line of the roller centers, and the length of the sine bar is related to the distance between the roller centers, with length values of 100 mm and 200 mm.

- For reducing weight, holes are made.

What are the main types of sine bars?

- Sine bars have different types, such as basic sine bars, compound sine bars, and universal sine bars that have certain features for angle measurements.

Define sine block.

- The sine block is a tool that is made with ground or lapped steel that is used for measuring the angle of different components. The sine block is a sine bar that has one niche width but is less wide than a sine plate. Sine blocks also operate as sine bars.

What precautions should be followed for a sine bar?

- The compound angle not be faulty or misaligned. Provide high accuracy for the sine bar. Use a longer sine bar for reduced errors.