The steam boiler is a closed vessel where water is converted into steam through burning fuel with the use of air at a set pressure, temperature, and mass flow rate. Steam is produced through a heat and water mixture. In industries, it is used for different manufacturing processes and gives heat and steam for different functions. In this post we will cover features, working, and related factors for steam boilers. Let’s get started. What Is a Steam Boiler?

What are steam boilers?

- The steam boiler is used to produce steam by converting heat energy into water. The steam boiler is basically a closed vessel that gets heat from fuel sources that convert water into heat that is used for different industrial processes like power production and heating.

- The main working of the boiler is that there is fuel combustion in the boiler combustion chamber that produces high-temperature gases that convert heat energy into water around the chamber; as a result, it boils.

- Steam boilers have different types, like fire tube and water tube boilers, that are used for providing heat and steam for different uses.

Basic Function of a Boiler

- As we learned, a boiler is a closed vessel that heats water to produce steam or hot water. that steam or hot water is used for different applications, like moving turbines for electricity generation, cooking food, sterilizing medical equipment, drying clothes, and powering industrial machinery.

- The working of the boiler based on uses. such as hot water boilers used for heating water at homes and industries, and steam boilers produce steam for power production.

- The main working principle of a boiler is that it heats fluid through heat transfer through the combustion process.

- The combustion process gets fuel through different materials like oil, natural gas, coal, etc.

- Heated liquids or fluids move through a heat exchanger, where their heat is given to other fluids like air or water.

- A boiler is the main component of different power generation plants. It is also used for different industrial processes.

- But its operations can be dangerous and require professionals for accurate working.

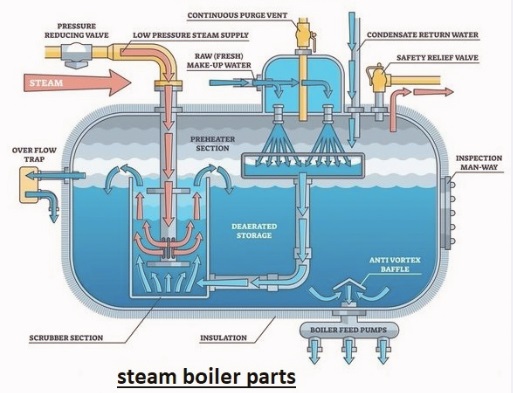

components of a boiler system

Pressure Vessel:

- The pressure vessel comes with gases or liquids at high temperature in high pressure. A pressure vessel is made with steel that has high strength.

Burner:

- Burners give heat to the boiler through oxygen and fuel combustion. Fuel sources used are natural gas, low-pressure propane, and coal.

Tubes:

- Metallic tubes are connected in a boiler that has water and high temperature. Firetube boilers have heated gas flow through one or more tubes, and high-temperature water surrounds the tubes.

Economizer:

- It is a heat exchanger that sends heat energy that can be lost in exhaust gases and uses this energy for heating water entering the boiler. As a result, low extra energy used for heating incoming water increases boiler efficiency.

Deaerator Tank:

- Deaerators are pressurized feedwater tanks that use pressure and heat for removing oxygen and dissolved gases from water added into the boiler. Dissolved oxygen and carbon dioxide cause corrosion on the boiler.

Heat Exchanger:

- heat exchangers transfer heat from one material to another without making these materials directly connected. In a boiler, hot gas goes to water through a heat exchanger.

Control Panel:

- • The control panel helps us to control boiler temperature and pressure. Commercial and industrial boiler control shows complete details.

Feedwater Tank:

- It is a collection tank that gives water to the boiler for producing steam. The feedback tank collects treated water and sends it to the boiler. boiler chemical that removes oxygen and protects metals in boilers that dissolved and mixed with the feedwater tank.

Combustion System:

- combustion system operated through a mixture of air and fuel that ignites for producing heat. In result, it provides an accurate air-to-fuel balance that is the main factor of the combustion system.

Reverse Osmosis System:

- It operated with the use of a high-pressure pump for increasing pressure on raw water of RO and forcing water over a semipermeable RO membrane that manages all dissolved impurities.

Chemical Monitoring Systems:

- It increases the working efficiency of boiler functions. Chemical monitoring systems accurately monitor chemical levels and give process analysis.

Fuel Types:

- combustion fuel source that generates boiler heating. Gas, oil, and coal are commonly used sources. Coal is used to provide high heating efficiency. in some applications but less common wood chip uses

Water Treatment:

- Water given to the boiler passes through treatment before being used in the boiler, which increases the boiler’s working life. different processes, such as water softeners and reverse osmosis, are used for water treatment and remove dissolved materials like magnesium to prevent any damage to the boiler.

- Feedwater tanks are part of water treatment since they use heat for reducing dissolved gases in water that cause corrosion in boilers.

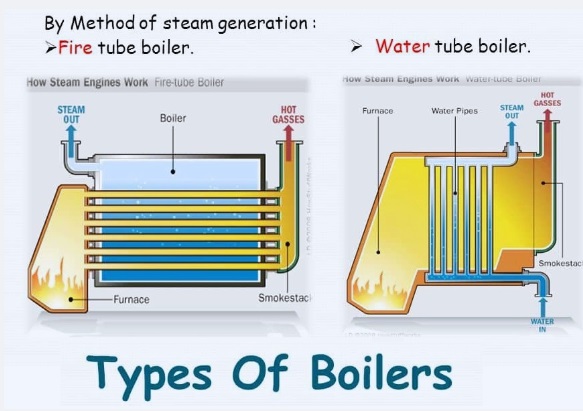

Steam Boiler Types

There are two main types of steam boilers: firetube and watertube boilers. These two come with their own features and uses.

Firetube Boilers

- The water chamber is the main design, and fire tubes pass through it. Hot gases from burning fuel move through tubes that transfer heat to water. This boiler has a simple design, so it is low-cost and easy to maintain. It is compact and uses a small process.

- Firetube boilers used only for steam pressure since they have a small main shell. It comes with a larger water volume that has a slow start-up.

- firetube boilers are good to use for low- to mid-level pressure steam, like for laundries, heating buildings, and small-level different processes of industries

Water-tube Boilers

- This boiler comes with different tubes configured in loop form. Water passes through these tubes, absorbing heat from combustion gases. The heated water was converted into steam and gathered in the steam chamber.

- watertube tube boilers have features to handle high steam pressure due to the design having separation of water and pressurized steam. Its starting process is high speed due to the lower volume of water in the tube.

- Its cost is higher since it has a complicated design, and it also needs high maintenance since it has different tubes and connections.

- It is used for high steam applications and is also part of power production and larger industries.

Electric Boilers

- The working of an electric boiler is the same as other types of boilers but has some different design features. It does not produce steam through use of heating but uses current for this purpose.

- So it is high efficiency. The boiler also does not have an effect on the environment and does not use fuel. It also does not produce any residue and needs low maintenance and requires less cleaning.

Low-Pressure Boilers

- Low-pressure boilers working like others but with a different design. Its pressure range is about 10 psi with a constant temperature value of 300.

- These boilers are used for constant temperature which requires more thatn variale temprature.

- This is commonly used since it provides higher speeds than other types.