Welding bead is important for good welding. Welding bead is more important than a line of metal, and for it, skill and accuracy are needed. For quality welding beads, there are different tools, such as augmented reality welding simulators are used. Here we will cover details for welding beads and their types and practical working. Let’s get started.

What is a welding bead?

- The welding bead is the outcome of welder motion when connecting two materials. It is a visible component and shows where the welding process was performed and gives an indication of the accuracy and skill of the welder.

- There are many types of beads in shape and size, and each has a certain function.

- The weld bead is a fillet made when two metallic components are connected for welding. It is caused when more filler metal is added for proper fusion and strength.

- The bead is over the surface on the butt joint. For the fillet joint, the bead is 45 degrees higher.

- The shape of the weld bead does not have details for the two metallic components. Internal defects such as cracks reduce joint strength, and low fusion occurs.

- Accurately made weld beads give details for welding work and provide quality joint creation.

Working of Welding Beads

Structural Strength:

- The main purpose of welding beads is to make stable joints. For making a solid bond, check that the bond easily passes through the base materials. The reliability of the structure is based on the strength of the bead.

Sealant:

- The welding bead is used as a sealant or barrier for gases to move through the joint. The solid bead controls gases to move in joints and also liquids.

Corrosion resistance:

- Welding beads also protect from corrosion. That resistance to corrosion is based on welding methods and the use of filler metal.

Transfer loads:

- Welding beads easily distribute load over joints since they work as a bridge between two working components. It is made for load distribution in an effective way and to avoid pressure application that can damage the structure.

Different Weld Bead Types

Stringer Beads

- The stringer bead is made with a pressing torch over the joint in a parallel direction with low motion on one side. At a dragging angle, electrodes direct forward at the time of weld instruct puddle. That is good for high penetration and solid welding.

- Welders apply pressure to the flame point at the time of working with fragile and heat-sensitive metals. That is performed by welding with an angle away from the puddle with a welding torch.

- Melted metal moves toward the direction in vertical connection. Through avoiding heat to reach puddle press weld, make it solid.

- The limitation of pushing is that its penetration through base metal is low compared to the molten pool. Irrespective of the narrow-width stringer beads used for any welding style.

- Make sure to connect the weld toe on both sides of the joint.

- Fusion is an important factor for base metal and weld; in some conditions welding puddle moves over both sides of the joint if the torch is properly handled.

Weave Beads

- For proper welding, weaving side by side over the joint is important. For fastly joining a joint is weaving beads. It is good to use for groove welds on thick levels; fillet welds come with weaves.

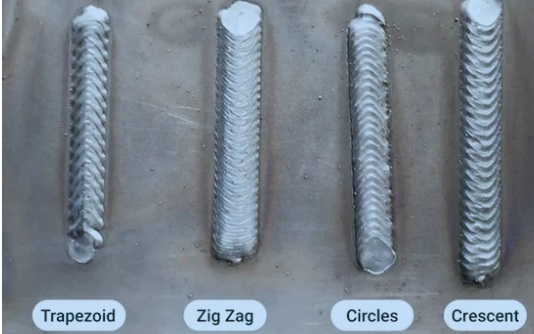

- Each welder uses certain weave types. Your hand moves in a zigzag, curly, or crescent shape.

- Weaving helps to control weld puddle heat that also fills beads.

- For making an accurate tie-in for the metallic component and minimizing undercutting edges, pause on the side of the weld.

- Move fast over the joint middle, and there is a risk of high crown, so it is good to use a flat convex weld face at the time of weaving.

- Triangle weave makes easy filling of steep pockets. Through use of the weaving method, we can control molten metal to move downhill at a time of 90-degree welding with the creation of a lodge below the puddle.

- Use a semi-circle weave at a central point over the front of the puddle to avoid overheating.

- Weaving overhead is difficult since molten metal is coming out of the weld through gravity’s effect. It is difficult to lay an overhead weave bead that is half an inch wider. Weaving is high speed as compared to the use of different string beads.

Whip Motion

- With the use of open groove welds, the stick welder makes a whipping motion with the wrist on the base path that is the first welding function. The main working is to use work plates with each other at the lower of flat bead of weld metal.

- E6010 and 6011 fast-freeze rods are common stick electrodes used for root passes with low-carbon steel.

- The welder operated the electrode over the gap. That is important for getting proper penetration. There is a keyhole seen on the opening at the head of the puddle.

- It is a difficult stroke for learning, with puddle dimension also working for keyhole size. If it is a larger size, do not fuse two sides. So heat control is important for root pass.

- For accurate joint design and welder setting control, size the keyhole with whip strokes.

- For controlling keyhole size more than the limit, whip the rod upward and ahead for the weld. It will reduce temperature and make keyhole size constant. It also makes the bead at the back side of the puddle become solid.

- When the bead becomes solid, whip back to the molten puddle, and another weld metallic drip falls on the rod, making another dime.

- Check rate of whipping with use of level of heat check in weld.

Whip Variation

- The changes in whip motion called J weave, which is a combination of crescent and whip stroke, are employed for the 2nd pass of the V-groove joint.

- Move E6010 electrodes from one toe to the other through the other, take a break on each side, and whip the rod over and upward and on the side of the joint.

- In this working longer arc, it is good to use.

Features of a Quality Weld Bead

Straightness:

- The bad need to follow edges connected without moving from sides.

Uniform Design

- The good bead comes with constant width over length and does not have any gap. The fillet weld is centered between pieces of metal as they cover each other.

Smooth toe transition:

- On this side sides of the bead connect with the working component material. The bead needs to flow on the working component and not have steep, also close to vertical, sides.

Smooth contour:

- Make a slight convex profile with low changes over bead length.

Low spatter:

The area over the weld needs to be clean and not have droplets of weld materials. That means the welder had wire feed and voltage value in the proper range.

Fewer defects:

- If you see a crack on the surface, that means there is more weld inside.

Smooth Penetration:

- For a butt weld, the weld extended through the material completely. In fillet weld penetration not assessed without working component sectioning.

No undercutting:

- If it exists, it can observe over toe. It exists where the bead does not fill the groove made at the time of weld creation and fit-up.

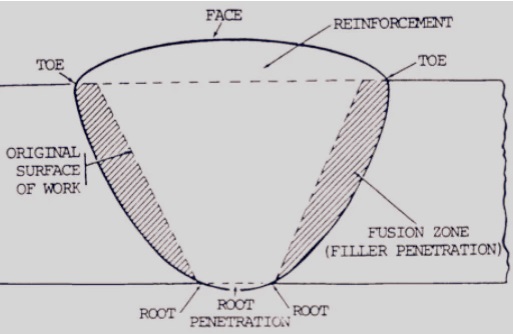

Components of Welding Beads

Face:

- After the welding process, the exposed surface of the bead is called the face.

Root:

- The deep part of the bead that passes into the base materials is the root.

Toe:

- The edge where the bead connects to the base metal is important for making a smooth transition and reducing stress concentrations.

Leg:

- The space from root to toe filler welds that is used for measuring weld size.

Defects in Welding Beads & Solution

Porosity:

- Porosity is the result of gas puddles becoming trapped in weld metal and making voids that affect bead strength. For controlling porosity, check that the working component and electrodes are clean and do not have dust, use proper shielding gas, and use accurate welding methods.

Cracking:

- It occurs when high heat is applied, high-speed cooling and residual pressure on the weld. Preheating of base materials, cooling rate, and use of welding methods avoid cracking.

Undercut:

- The undercut groove over the toe of the bead that affects the joint. It is the result of high heat or an improper welding angle. For controlling undercut, properly use heat value and set an accurate angle and speed at the time of welding.

Spatter:

- Spatter comes with small metallic droplets that splash out of the welding pool and, as a result, make an uneven bead. The use of accurate welding features, stable arc maintenance, and anti-spatter spray reduces spatter.

Incomplete Fusion:

- Incomplete fusion is the result when weld metal does not accurately bond with base materials. Provide enough heat input and accurate electrode angle to avoid incomplete fusion.

FAQs

Define bead in welding.

- The welding bead is a pass made with a welding torch or electrode over the joint. It is also defined as a welded metal deposit that makes a raised surface on a working component. Bead creation is based on different passes over a joint with a welding torch or electrode.

How is a welding bead formed?

- Welding beads are made when filler metal and base metal are heated to their melting points. When filler melts, it makes a molten weld pool that can flow and use components. When it becomes solid, the result is a welding bead.

How much thickness of weld bead?

- Make sure that the size of the weld bead does not cross the thickness of the thin component connected. The least size for a loaded cyclically loaded structure is about 3/16 in.

What is a straight weld bead?

- The hydrogen 7018 rod is a straight bead. That is also called stringer beads since it is narrow and regular. It is used for flat, horizontal, and overhead stick welding. Vertical 7018 welds have features of a weave pattern.

What are features of a good weld bead?

- The good bead follows edges joined without moving side to side.

- It has a uniform design and constant width over length and does not have any gaps.

How to finish a weld bead?

- Fuse rod into weld pool for keeping at the same height. Maintain constant travelling speed and rod motion for getting uniform bead width and proper fusion.