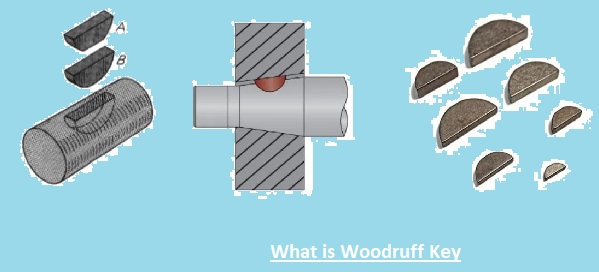

The Woodruff key is known as the half-moon key, which is a semicircular machine shaft key that controls the independent motion of gears, hubs, and other parts to move freely of the rotating shaft.

A Woodruff key is a semicircular disc configured into a circular recess in the shaft, and Woodruff’s keyway cutter is used for the machining process.

These keys are called semicircular pockets that operate into shafts for holding woodruff keys. This post is shaft-cut with the use of a woodruff keyway cutter. The lower circular part is hammered on the shaft, and the upper flat part is put into the hub. In this post, we will cover details for Woodruff Key features and details.

Introduction to Woodruff Keys

- Woodruff keys are semi-circular discs that are used for making connections of machine components with rotating shafts and spindles.

- It is used for controlling the free motion of gears and other parts through a rotating shaft and is connected to recessed key seats cut on the shafts.

- After installing gear or other machine parts with a keyway fitted on the shaft, until the woodruff key interfaces with the component keyway.

- Through avoiding motion, woodruff keys work as a fail-safe that avoids shearing of components as a result of high pressure.

- Woodruff keys are made with different materials and key stocks that are high-carbon steel and stainless steel.

- They are configured into a Woodruff keyseat, which is a half-moon slot cut on the rotating shaft through a Woodruff cutter.

- • The long and flat side of the key connected over the host shaft when it is put into the keyseat, and the connecting component with a pre-cut keyway is put on the host shaft.

How to Install a Woodruff Key?

- The installation process of the Woodruff key is easy and simple. Just press the semi-circular key through the way given in the shaft manually with force.

- If it’s not fixed with the keyway, manually hammer the key without avoiding any breakage.

- When the Woodruff key is fitted on the shaft, then no further alignment is needed, and the flat side of the key is parallel with the host shaft.

- In some conditions, the Woodruff key shows grooves as mating components are pressed at the time of installation of the keys, and it makes the installation process difficult.

- Ensure that the hammer is used slowly through the use of force for proper installation.

Types of Woodruff Keys

Full-Radius Woodruff Keys

- It is a standard woodruff key that comes with a complete circle dimension and is made for completely interlocking with the shaft key seat. The key seat comes with an accurately cut base based on key size for handling the key and avoiding connection between the key height and the death of the host key seat shaft.

Flat-Bottom Woodruff Keys

- It is the same as full radius keys, but its lower part is flatter than a rounded shape. that provides easy connection since it avoids the key moving in the key seat and also reduces any interference at the base seat.

- that helps Woodruff key to make a connection with the key seat and also manage any clearance problem related to tall Woodruff keys.

Hi-Pro Woodruff Keys

- Profile Woodruff keys are also called hi-pro keys, which are a type of full-radius Woodruff key that comes with feet at the protruding component of the key. These feet avoid the Hi Pro key through wobbling in the rounded key seat since it extends to the host shaft face.

Woodruff Key Materials

- Woodruff keys are made with the use of alloy steel, like high carbon and stainless steel, and are commonly made.

- They were also made with soft metals like copper and tin alloys. In some applications, ceramics are used.

- Different shapes are used for making keys. Shafts are made with high carbon steel, and some other materials are used.

Other Types of Keys

Rectangular/Square Keys

- They are parallel keys since both rectangular and square types provide constant thickness and width over component length. It does not have a taper and is used in applications where the mating component slides over the shaft. A parallel key is used for transferring unidirectional torque through low starting loads.

Feather Keys

- These keys are designed to help make a connection with the shaft or hub by providing relative axial motion of the keyed joint. such as the mating part connected with the use of a double-headed key and the assembly applied on the shaft.

- When the key is put on the shaft, closed mating grooves are curved on the surface of the shaft, providing axial motion of the key and holding through providing axial motion of the mating part.

Gib-Head Keys

- These keys are used for power transmission to bind gears and pulleys to the shaft. The head of the key provides protection from shaft damage and handles force through hammering installation and accurately fits through the protruding gib head, which shows a strong connection.

Advantages of Woodruff Keys:

- Woodruff keys are used to minimize stress and provide safe working of the shaft.

- This key is easy to remove and has a simple design.

- It provides accurate fitting and reduces motion of the key seat.

- It has easy adjusting features.

- The Woodruff keys are accurate to provide high-speed functions.

- It reduces the chance of rolling over the shaft and is used for high-speed rotation applications.

Disadvantages of Woodruff Keys:

- Woodruff keys are not used for high load capacity features and are difficult to connect.

- It minimizes stress, and if a key comes with a deeper keyway on the shaft.

- These keys are not used for heavy torque transmission.

- Keyway depths affect the shaft strength, and keys do not provide axial motion between the shaft and hub.

conclusion

The woodruff key comes in the shape of a semicircular disc fitting on the recess of the shaft. These keys are good for high-speed rotation assembly so are part of gears and pulleys on shafts.

FAQs

What is the purpose of the woodruff key?

- Woodruff keys are semi-circular discs that are part of connecting machines components with rotating shafts and spindles. It is used for stopping gears and other machine components from moving independently from the rotating shaft and is connected to recessed keyways cut on the shaft.

What is the difference between a parallel key and a woodruff key?

- woodruff key not carry a load like parallel keys. The feature of a woodruff key is that it handles taper in the hub keyway, and its depth prevents the key from turning over.

What is a use of a woodruff key?

- Woodruff keys are used to make connections of machine components with rotating shafts and spindles. It is also used for mechanical transmission for providing accurate alignment between the shaft and the transmission component.

Are a square key and a woodruff key the same?

- Parallel square and rectangle keys are side-fitting over upper clearance and normally retained in the shaft more strongly than in the hub. The Woodruff key is a half-moon-like-shaped key and is put into a curved slot in the shaft.

What is the strength of a woodruff key?

- Woodruff keys are C45+C key steel that comes with a minimum tensile strength of 60 kg/mm².

Why is it called a woodruff key?

- Woodruff key names come from Woodruff Manufacturing Company of Connecticut, US.

Should the Woodruff key be tight?

- For keeping the woodruff key in position at the time of installation of mating components, make it tightly enclosed in the key seat.

What are the limitations of a Woodruff key?

- The limitations of the Woodruff key are that the depth of the keyway affects the shaft, it is not used as a feather key, and it is difficult to connect because it is small and cannot carry a high load.