The car steering system is the main part of any vehicle that controls the vehicle according to driving requirements. Effective steering controls provide safe driving. Essentially, the car’s steering system enables the vehicle to move according to the required turn. Vehicle effective control for a different speed range is important through an accurate steering system.

In this post, we will cover the detailed features of the car steering system. Let’s get started.

What is a Car Steering System?

- • The car steering system comes with different parts that work in combination to get the input of the driver’s instructions for car control.

- Instruction executed through conversion input for a certain steering wheel in wheel movement.

- The main working of the vehicle steering system is also called vehicle direction change. It not only varies the direction, the steering system also provides stable turns in the right direction.

- The steering system also gives feedback on road conditions, and we get a proper driving experience.

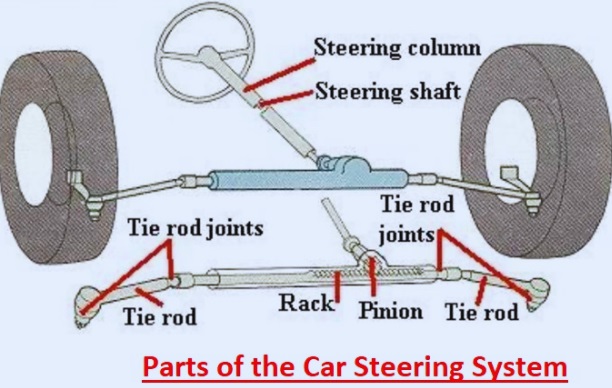

Parts of the Car Steering System

- The car steering system comes with different parts that work in combination to get the input of the driver’s instructions for car control.

- Instruction executed through conversion input for a certain steering wheel in wheel movement.

- The main working of the vehicle steering system is also called vehicle direction change. It not only varies the direction, the steering system also provides stable turns in the right direction.

- The steering system also gives feedback on road conditions, and we get a proper driving experience.

Drag link

Read also Why Are My Car Brakes Grinding?

- drag link used for conversion, sweeping arc, existing steering arm into linear motion in other steering links.

- The drag link makes a connection of the pitman arm with the steering arm also connected with the tie rod assembly.

Steering arm

- It is used for transmitting the turning force of the steering gear to the drag link in an automotive vehicle.

- • The main working of the steering system helps the driver with safe and accurate steering of the car.

- • The steering system also gives techniques for minimizing hindrance by making it easier to overcome.

Stub axle

- When the steering wheel rotates, movement is transmitted to the pitman arm with the gearbox. That motion is sent to the drag link. After that, movement is transmitted to the stub axle that causes rotation of the kingpin, resulting in the right wheel.

Left spindle and king arm

- steering knuckle comes with a wheel hub and connects suspension and steering parts. It is known as a steering knuckle, spindle, or hub.

- The wheel and tire assembly connects to the hub or spindle at the point where the wheel moves and holds stable plane movement due to the knuckle

How Does a Steering System Work?

- The basic working of a car steering system transforms rotational motion into angular displacement of the wheels.

- that is done with the following different systems according to the steering system.

- Here, the rack and pinion system of steering is explained.

- A pinion makes a connection with a metallic bar or rack with the help of teeth.

- When we turn the steering wheel, we make a connection of the shaft and gear.

- Teeth help make a pinion direct connection of a metallic bar or rack. During steering wheel rotation, the pinion moves, and the control rack moves left or right according to the driver’s instructions.

- The rack makes a connection with the wheels through tie rods; the set wheel angle is based on the car’s design.

- During rack motion, the tie rod pushes or pulls, causing wheel movement in a certain direction.

- Steering systems like power steering come with more parts for uniform working.

- Those parts are sensors, motors, and hydraulic pumps.

The summary of the steering system’s working is as

- The steering wheel causes the rotation of the steering column.

- steering gearbox connected at the column; as a result, when the wheel moves, the cross shaft of the gearbox causes oscillation

- cross shaft is connected with a drop arm, which is connected through a drag link with steering

- steering arms of the wheels, connected with tie rods to the drag link

- Due to steering wheel operation, knuckles move forward and backward; as a result, the steering moves connected with the knuckles.

- drag link is connected with the tie rod at one end, and the other connected with the end drop arm.

Steering system types

- car steering system comes with different types based on the working that are

Rack and Pinion Steering System

Read alsoSymptoms Of A Bad Strut Mount

- Rack and pinion steering is a simple design and a compact system that has a shaft, pinion, rack, and tie rod that helps to provide car control.

- car steering wheel is connected to a shaft that causes the rotation of the pinion gear. The pinion comes with a metallic bar that is a rack.

- When the steering wheel turns, the pinion moves and controls the rack. After that, rack any side left or right.

- The rack makes a connection with the car wheel through tie rods and sets the wheel angle based on the car’s body.

- Rack and pinion is used for high-performance vehicles due to the accurate gear design.

Power Steering System

- The power steering system provides an electric system and minimizes driving force. The main types are hydraulic power steering (HPS) and electric power steering (EPS).

- HPS uses a hydraulic pump operated with an engine, giving pressure-based fluid for steering movement. The control valve transmits fluid to any side of the piston configured with the steering rack, causing wheel rotation.

- EPS system is used as a replacement of a hydraulic pump, having a motor-based sensor control and an electronic control unit (ECU).

- The electric motor gives accurate torque that provides driving speed and smooth operation.

Power Steering System: different types

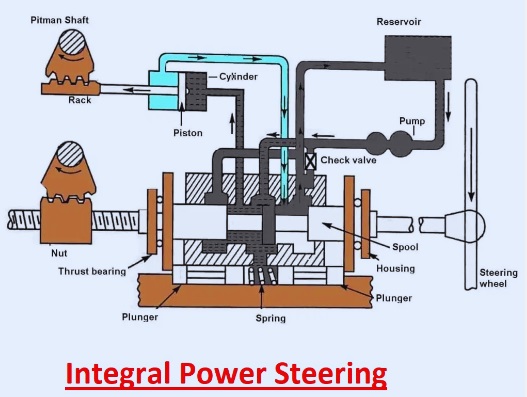

Integral Power Steering

- This type has a ball bearing nut steering gear and a worm and hydraulic rack piston aligned over the worm shaft, which moves the nut in a different direction with the help of hydraulic pressure.

- reaction connection valve configured with a worm shaft, thrust management with a link, and an actuator lever. The motion of the thrust bearing results from control valve movement through the opening and closing of the oil path in the valve body and housing of the assembly.

- • The internal working circuit of this steering system is shown in the diagram below.

- If the vehicle moves forward, oil moves through the pump when the valve center is open and then towards the storage area.

- It’s another movement point on both sides of the rack piston for working like a lubricant. Its other name is power cylinders.

- During a right turn of the vehicle, the worm moves downwards to the left through the wheels, steering linkage, pitman shaft sector, and turn of the worm towards the ball nut.

- As a result, apply force over the thrust bearing, resulting in actuating the lever and control valve connection with causing the control valve to the area shown in the diagram.

- The fluid path for the right turn cylinder increases, and for the left turn cylinder, it is narrow.

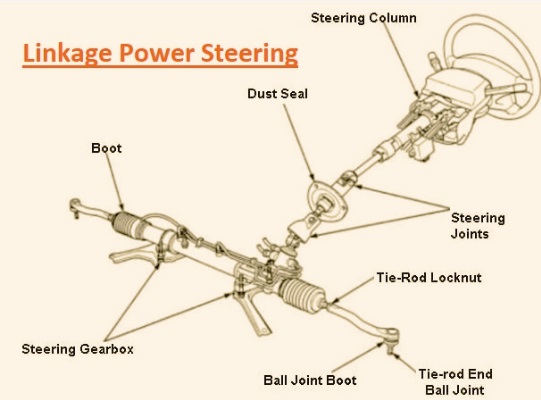

Linkage Power Steering

- In this type, the power cylinder is not configured with a steering gear. It is configured to steer the connection.

- Valve design tilted on the steering connection for distinct assembly with the power cylinder.

- power applied for direct connection

- Here we can see the linkage power steering diagram in the neutral condition. When the vehicle moves straight, the spool valve of the control valve layout is configured in the middle through the centering spring.

- Oil easily moves towards the power cylinder and out of the valve band, then goes to the pump reservoir.

- During a left turn, the force increases the pitman arm, causing movement of the spool control valve to eliminate pressures applied through the center spring; as a result, the valve moves to the right of the valve structure.

- Where it makes a connection from the left side of the power cylinder to the returning lining, it causes pump storage and oil pressure towards the right side of the cylinder.

- In the results, the cylinder housing moves to the right side, which causes movement of the relay rod in the right direction for the front wheel’s right turn.

- In a right turn, a reversed state occurs, and the relay applies force for turning right.

Hydraulic Power Steering

- Hydraulic power steering is not an old method, just about 100 years old. It’s an older type, different compared to the new hydraulic system, and part of heavy vehicles.

- Modern hydraulic work with fluid and hydraulic pumps causes the steering torque to minimize forces, and the steering wheel easily moves at the central point.

- working feature of this system based on a hydro-mechanical servo. in this system, force is applied in the same direction as the driver and has high torque.

- That high torque increases the steering input of the driver, causing smooth movement.

The steps involved in working of this system are

Read alsoMain Symptoms Of a Bad Timing Chain

-

- When the driver moves the steering, the hydraulic pump connected with the engine shaft causes the pumping of hydraulic fluid from the storage area to the hydraulic chamber.

- The hydraulic pressure applies force on the piston in the chamber.

- High-pressure fluid causes the rotation of the pump shaft, rotor, and cam ring of the hydraulic chamber. That rotation provides high torque for steering.

- High-pressure fluid from the hydraulic cylinder is given to the pinion, which moves forward to the rack gear and finishes for front wheel rotation.

- • The coupling system causes transfer of torque from the pinion to the front wheel.

Electric Power Steering

- This steering system is also new and considered an advanced power steering system.

- where the system is completely restored through motors and sensors through hydraulic power steering.

- In this system, a motor-based vehicle battery is used to apply force on the steering gear.

- Steering gear and torque get from the motor and are regulated with a sensor that detects the location of the steering column.

- When we give input through steering, sensors on the steering column get input and transmit a signal to the vehicle’s electric control unit.

- The ECU system checks the input and transmits a voltage signal to the motor at the steering column, where the gears are in mesh with the pinion gear.

- • The voltage signal of the ECU operates the motor operated with the vehicle battery, and the torque is based on voltage signals.

- Motor control gear that is connected to the pinion gear through a mesh that is part of the manifold transmits torque to the pinion gear and employs torque at the rack where it is connected.

- With torque configured with the pinion on the rack, the rack moves and causes the front wheels to rotate.

Different faults of Steering Problems

There are different faults that occur for steering due to different reasons. The main common steering errors are

- when you face difficulty with wheel rotation at low speeds or in a rest condition. That is due to low power steering fluid or damaged components.

- • A proper response does not occur through the steering wheel; that is due to a damaged part of the steering system.

- If the steering wheel causes vibrations during high speed and turning. High shaking in different vehicles is known as death wobble. That makes control difficult for vehicles and increases the chances of accidents during high-speed driving.

- When moving the vehicle left or right, not maintaining a straight direction causes difficulty for control maintenance and increases the chances of an accident.

- The grinding noises of cars also cause steering damage due to worn parts.