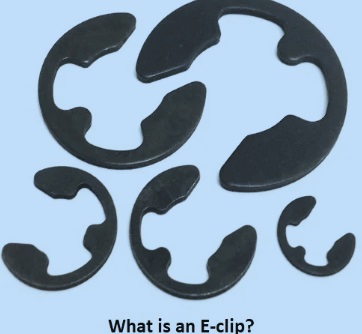

The E clip is used for holding components or assemblies on the shaft, also in the bore when connected in the groove. The other name of the E clip is the E ring, which comes with 3 prongs. also called stamped clips that are configured in machined grooves with small-sized tubes and shafts.

The E clip is made of carbon steel and has a phosphate finish. Its three prongs connect with the lower part of the groove and provide space for circlip or C-clip pliers. The main uses of E-clips are in car engines and locking systems. In this post, we will cover details for e-clips and their working.

What is an E-clip?

- The circlip, also called a C clip or snap ring, is a type of retaining ring having an open end that snaps at the point. Circlips are fasteners that fit into radial grooves of shafts and holes that spring for a strong connection.

- Standard circlip, like a snap ring, removed with the use of a certain type of C-clip pliers.

- The E ring, or ring clip, is a circlip that goes on or off a grooved shaft without the use of any special type of tool.

- All circlips have a design like C that helps to fit around the shaft or compress when connected in the hole.

- The ring clip is also called an E ring or Eclip, like the letter E.

- It is a commonly used type of external circlip. Standard circlips come in internal and external types. Internal circles are configured in grooves of holes, and external circlips are strongly fitted into grooves externally to the rod or shaft.

- Their main use is to replace mechanical fasteners and also minimize assembly weight. They have a longer working life than mechanical fasteners.

- The main feature of E-clip is that it is easily pressed into the machine’s groove without the need for a certain type of tool.

- It also does not use a circular shaft; basically, its main function is to provide better support to fasteners, reducing the use of threading and tapping.

- E ring comes with a 3-prong that helps to make the connection with the lower part of the groove, which helps to provide a place for strong assembly retention.

- The size of the E clip is the highest diameter of the grooves for which the clip is made. The other factor is throat width and free diameter.

- The throat width is the opening size, and the free diameter defines the external diameter. In relaxed conditions, these two values are measured for the ring clip.

Removing Process for E-Clips

There are different methods used for removing E-clips; some are explained here.

Use of E-Clip Remover

- For this technique, first of all, set the removal tool at the edge of the E clip. E-clip removers come with a smooth, curved edge.

- Configured the curved edge of the tool with an E-clip curve and put the tool under the E-clip. E-clip removers come in different types and work in the same way.

- Push up and apply moderate pressure; when the tool is configured with an E clip, just push the tool to remove it. Do not apply high pressure; set the E-clip at the dry location until the next use.

- E-clips can be used many times and put in a storage jar.

Use of Pliers

- For this removing process, move the center of the E clip same time for strong grab. For easy removal of the E clip, the curved side of the E clip is set towards you. With the use of needle-nose pliers for twisting. The E clip can easily move with low pressure, so do not apply high pressure.

- Handle the central point of the E clip with needle nose pliers, squeeze the middle point of the E-clip with the tip of the needle nose pliers.

- Strongly hold the pliers for removing the clip. Needle-nose pliers are good for removing the E clip. For this, a slip joint plier or a locking plier is used.

Size and Materials of E clip

- The E clip size is equal to the maximum diameter of the groove for which clip is made. Other parameters are neck width and free diameter.

- Neck width is the opening size, and the free diameter is the external diameter. These two values are calculated at the time of relaxed conditions of the ring clip.

- There are different types of materials used for the manufacturing of E-clips, such as copper, stainless steel, and alloy steel, based on applications.

Advantages & Disadvantages of E Clip

Advantages

- The features of the E-clip are that it is easy to push in a machined groove without certain tools, and it can be pushed on or off the shaft through the use of a pair of pliers or a screwdriver.

- It does not use a circular shaft, and it has good features compared to fasteners of other types, reducing the use of tapping and other machining functions.

Disadvantages

- The main disadvantage of E-clip is its limited load-bearing capacity based on its uses.

- If it is overtightened also affects the shaft and working performance.

FAQs

Are E-clips and snap rings the same?

- As compared to a snap ring that slides over the axis of the shaft, removing an E ring is easy to do from the side without any movement over the axis. The size of the E-clip is the maximum diameter of the grooves where the clip is made.

What is the replacement for the E-clip?

- • The snap ring is easy to remove and again insert as compared to E-clips. Since they have replaced E-clips on different tools with snap rings for high-speed maintenance and an easy process.

Can e-clips be used again?

- You can save old E clips so you can reuse them. That is done with jaws relaxing, holding the end of the strap on the clip. The easy process is to slide the E-clip on the frame, as compared to the slow fitting of the clip at the frame when the clip is connected to the frame.

What is the basic function of E-clip?

- The E-clip is a fastener that controls components or assemblies on a shaft and a bore when connected in grooves. When connected, the exposed part works like a shoulder that retains a certain component.

What is the difference between C and E-clip?

- • E-clips are connected radially and come with a larger shoulder compared to C-clips. Wider shoulders give larger retainer areas and, as a result, high thrust load features.