The plunger pump is a positive displacement pump that comes with a high-pressure static seal, and the smooth cylindrical plunger moves over the seal. That is different from piston pumps and is used for high-pressure applications. It is also used in the transfer of municipal and industrial sewage. In this post, we will cover details, features, and related factors. Let’s get started with an introduction to the plunger pump.

What is a Plunger Pump?

- A plunger pump, also called a reciprocating pump, is a positive displacement category used for different industries where high pressure is needed.

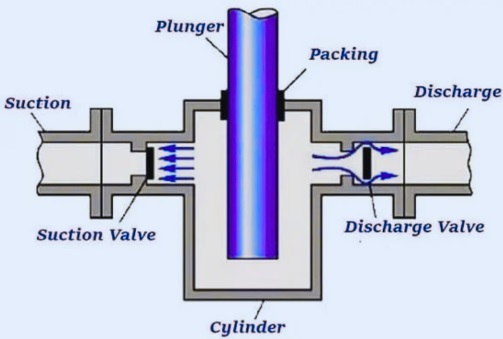

- It operated with one or more plungers that move front and back in the cylinder and provide suction force on the intake side and release fluid on the discharge side.

- The main part of a plumber’s pump is a cylinder that comes with a plunger and provides a required sealed chamber for fluid movement. It is made with stainless steel or ceramic that bears high pressure and shows resistance to corrosion.

- For minimizing leakage between the plug and the wall of the cylinder, there is a retaining ring over it.

- The plunger pump operated with the use of varied pressure and relieve at the time of stroke. In these conditions, when moving away, it causes a vacuum in the chamber and attracts liquid through the intake valve.

- While moving away from each other, compress liquid and apply force through the discharge valve.

- The pumping speed, diameter of plunger, and discharge valve define the pressure generated at that point.

- It is used where high accuracy and high pressure are needed, which is achieved with a plunger pump, so it is used in oil drilling, water jet cutting, and chemical injection.

Plunger Pump Working

- Plunger pumps are positive displacement pumps that use a plunger or a piston to move fluids in a cylinder chamber. The plunger is operated with steam-operated hydraulic or electric drive.

- Rotary position and plunger pump operated based on crank operations for making reciprocating motion over an axis that produces pressure in the cylinder or forces fluid through the pump.

- Pressure in chambers operates valves at both suction and discharge points.

- Plunger pump used for applications where pressure in the range of 70 to 2,070 bar was needed.

- Piston pumps are used for low-pressure applications. The volume of fluid discharged is equal to the area of the plunger product with stroke length.

- The total capacity of the piston pump and plunger pump is measured through piston area, stroke length, piston number, and the speed of drive.

- Power used for the drive has a direct relation to pressure and pump capacity.

- Seals are an important component of piston pumps and plunger pumps that operate power fluid from the medium that is pumped.

- The stuffing box is used for sealing the connection between the vessel where the medium is transferred and the plunger.

- • The stuffing box comes with bushings, packing, and a gland.

- Materials used for plunger pump components are used for wear and connection with the medium type.

- The main materials are brass, bronze, steel, iron nickel alloy, etc.

- Plunger pumps that operate in oil services come with an iron cylinder and plunger.

- Plunger, discharge valves, and suction valves make connection with the transferred medium, and the materials selected are based on fluid movement.

- The projects where continuous duty plunger pumps used solid ceramic plungers for connection with water and oil and not used for high acidic mediums

Rotary, Piston, and Plunger Pumps

Rotary Piston

A rotary piston pump operated with piston motion back and forth over rotor grooves moves liquid into the inlet. 2 direct-operated pistons move in the cylinder reciprocally, with the piston moving back towards the pump middle when the pump inlet results in fluid draining into the inlet.

When the rotor moves towards the outer part of the pump, the piston moves over the rotor and releases fluid through the outlet.

Piston Pumps

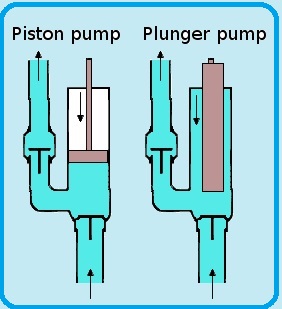

- piston pump work with a piston pushing a seal moving back and forth in a chamber that makes vacuum and pressure. The seal is disc-like in design, and fluid moves through a hollow cylinder called a piston made with ceramic.

- Piston pumps are used for single-piston or multiple-position work at different intervals for making smooth flow levels.

- Piston pumps are also called 3, 5, or 7 frame pumps, which shows the number of positions in the pump head.

Plunger Pumps

- Plunger pumps are types of pumps where the plunger moves back and forth in the stuffing box, changing volume. It is good to use for high pressure since the seals are static in the pump that reverses to position the design where the seals move in the hollow chamber.

Piston vs. Plunger Pumps

| Piston Pumps |

Plunger Pumps

|

| it is high pressure seal reciprocating in piston cylinder |

The high-pressure seal is static. plunger slide through seal, helping pump to be used for high pressure.

|

| Inlet pressure value is 8.5psi to 40psi |

Inlet design pressure value is 60-70psi.

|

| it is used for short duty cycles till second pump work in slow way. |

it provide continuous operation when ran slowly.

|

| Inlet mechanically actuated. |

it uses flooded suction or higher inlet pressure of booster pump.

|

| Output pressure 100-1200psi |

Output pressure 100 to 10,000psi

|

Applications of Plunger Pumps

The main uses of plunger pumps are as.

- Plunger pumps are used in the oil and gas industry for pumping drilling mud and different fluids in the wellbore at high pressure. It helps to keep the wellbore in a stable state and avoid blowouts.

- Plunger pumps are also part of treatment plants that pump water in filters and other treatment devices with high pressure. It removes impurities and contaminants in water.

- Plunger pumps are used for chemical processing plants for pumping of chemicals and fluids at high pressure. It ensures proper mixing of chemicals and transportation in a safe way.

- • A plunger pump is used for an irrigation system that pumps water with high pressure in fields. So proper watering is applied for crops.

- Plunger pumps are also used for power plants to apply pump water or other fluids in steam turbines and other devices with high pressure.

Advantages of Plunger Pumps

- It comes with self-priming pumping features and provides high efficiency.

- It has high discharge pressure and linear capacity control for variable speed uses.

- It has features to produce higher pressure than a piston pump, and flow rates and pressure vary slowly.

- It can pump in slurries and also move high-viscosity and high-weight materials.

Disadvantages of Plunger Pumps

- It is high weight and has lower flow than a centrifugal or axial pump.

- It causes pulsation due to irregular flow and causes cavitation due to acceleration head if you have a longer suction pipe.

- It has high vibration due to reciprocating motion since rotational speed is lower than

- Irregular flow causes pulsation in dynamic pumps.

- It is high cost and needs regular maintenance.

- • The plunger pump does not have pulsating free flow. It has features to handle low-flow-rate fluids.

Read also:Bead Blasting: Features, types & Process

FAQs

What are the main uses of a plunger pump?

- Plunger pumps are used for disinfection, portable sanitation, soft wash, and applications where high pressure is needed. It is configured on electrical power-based devices such as misters and sprayers.

What are the limitations of a plunger pump?

- The limitations of plunger pumps are pulsating delivery, and for larger units, they need more area, larger mass, and a high cost per unit of pump output.

What is the difference between a plunger pump and a piston pump?

- The basic difference between a plunger pump and a piston is based on the sealing process. In piston pumps, a high-pressure seal reciprocates through the piston, so the seal moves in the cylinder.

- In plunger pumps, the seal is static, and the plunger moves through it. The basic difference in seal location affects pressure features durability and required maintenance.

What are the benefits of the plunger pump over the piston pump?

- Plunger pumps come with a simple design and few components and need less maintenance as compared to piston pumps.

What is the working of a plunger?

- In plumbing, plunger work defines handheld tools that are used for clearing blockages in drains and pipes. Plumbing plungers come with rubber suction connected with a shaft of plastic.

What is the maximum pressure range of a plunger pump?

- The high pressure for the plunger pump is the high pressure that the pump produces without affecting working performance or damaging any components. the high pressure in the range of 1000 to 5000 psi according to the type of pump

What are the parts of a plunger pump?

- The main components of a packed plunger pump are as follows.

- stroke adjuster, piston controlled with TFE composite bearing in motor cylinder.

- Piston return spring made for non-rubbing on plunger.

- true deal seals.

- plunger seals that are lubricated with synthetic grease.

What is the difference between axial and triplex plunger pumps?

- Axial cam pumps are direct drive, which means they spin at the same speed as the engine speed. It wears down faster as compared to a triplex pump, with good pressure and working features. Triplex plunger pumps are high-quality pressure washer pumps that provide a longer working life and good performance.