The camshaft position sensor and crankshaft position sensors are made to provide ignition and fuel injection signals, giving power to the vehicle. These sensors give a signal to the electronic control unit and track the working of different engine parts. The working of the camshaft position sensor records the position of each camshaft rotation. ECU gets data from this sensor for the working of spark timing and fuel injection.

In this post, we will cover the detailed features of the camshaft position sensor and its related working.

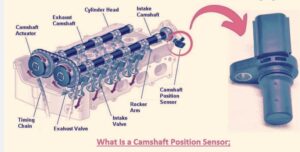

What is a Camshaft Position Sensor?

- A camshaft position sensor is an electronic device employed in an engine for measuring rotation and camshaft position, and that information is sent to the engine control module (ECM).

- ECM, according to this data, controls the command spark and fuel for high efficiency of the engine.

- The proper ignition of the fuel mixture increases engine power and fuel efficiency increases, which minimizes tailpipe emissions.

- In different engines, the camshaft position sensor indicates which cylinder is in the power stroke according to crankshaft position, which gives accurate fuel and spark for starting the engine during acceleration.

- This sensor is connected to the engine to make a strong electrical connection. The camshaft position sensor is small in size but has good magnetic features.

- Camshaft sensors use a magnet to produce a signal that is used in conjunction with the sensor to define the position relative to top dead center (TDC) on the compression stroke.

- This data is used for fine-tuning of spark timing and injector pulse. That’s called a cylinder identification sensor.

- ecu fuel injection system that controls ignition for each cylinder in series. The cylinder identification sensor transmits details. If the cylinder is on top dead center at the time of engine rotation, the sensor sends a signal to the onboard controller (TDC).

Functions of the Camshaft Position (CAM) Sensor

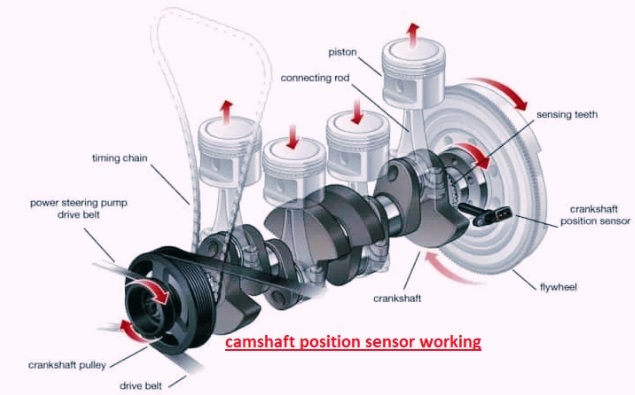

- The basic function of the camshaft position sensor is to find which cylinder is on the power stroke. The car computer uses this sensor for monitoring the rotation of the camshaft according to the crankshaft.

- This data is used for managing spark timing and fuel injector function. The cam sensor, also called the camshaft position sensor, sends camshaft position details to the ECM.

- Crank and cam sensors operate at the same frequency.

- In a series combination, a cam sensor is used to define which injector needs to fire, and for a coil-on-plug ignition system, a coil fires.

- The camshaft position sensor, gathers and sending data on the car’s camshaft speed to the ECM.

- These details help ECM to define ignition timing and the fuel injection needed for the engine. These signals help the engine to operate well.

CAM Sensor Working

- The camshaft position working process is easy and simple. In this working, ECU is a sequential fuel injection system that decides or controls the ignition of cylinders in sequence.

- either with the cylinder at first top dead center at the time of engine rotation. The sensor sends a signal to the onboard controller (TDC).

- As a result, the time of pulse injection is measured.The onboard controller and fuel injection modules do not detect cylinders since they are not used for system working.

- The accurate cylinder is found when the crankshaft ignition signal gets through the detection locations of the crankshaft, camshaft, or distributor shaft.

Types of Camshaft Position Sensors

Magnetic Type Sensor

- • The magnetic camshaft position sensor comes with 2 wires. It produces an AC sine wave. This sensor exists in the distributor or external area of the camshaft.

- It is close to the camshaft, which comes with a permanent magnet connected. When a magnet moves through a sensor, a magnetic field is generated, and a signal is produced sent to the ECM for further processing.

Hall Effect Sensor

- This sensor comes with 3 wires; one wire is used for reference power, the 2nd is ground, and the 3rd is used to transmit the signal to the computer. The Hall effect sensor exists in the distributor or on the camshaft, like the previous sensor.

- It comes with a screen that has a slot and a magnet connected to the shaft. The sensor gets on and off due to screen movement between the sensor and the magnet.

A.C. Output Sensor

- It is known as a special camshaft position sensor that produces an AC signal. ECM produces high frequency in the range of 150 to 2500 cycles for the exciter coil that is close to the rotating disc.

- This disc connected at the camshaft end has a slotted design. If a slot passes through a coil, it gets excitation through mutual induction, and the first cylinder position moves to the ECM.

Symptoms of a Bad Camshaft Position Sensor

The check engine light is on.

- If your camshaft position sensor is not working, check on the dashboard to see if the check engine lights are on. If it’s on, it means there’s a sign of a malfunctioning camshaft position sensor.

bad fuel efficiency

- if your car is using more fuel than normal and lacks fuel for the engine. The camshaft position sensor is not delivering proper information to the engine control module. It can open the fuel injector,sending extra fuel to the combustion chamber.

- This faulty data of the camshaft sensor affects engine working efficiency.

poor ignition

- If the camshaft position sensor is affected at the time of driving, the engine loses power, and as a result, the car starts shaking. It is because the ECM is getting faulty data from the sensor, which results in a bad quantity of fuel in the cylinders.

Engine Stalling

- The engine’s condition is stalled, not the car, during driving, because the fuel injector is not getting instructions to feed fuel into the cylinders.

bad acceleration

- If the sensor starts damaging, the vehicle starts jerking and faces difficulty for accelerations. In some conditions, the car does not move some miles. This fault occurs due to a bad fuel supply through the injector.

Bad Fuel Mileage

- It is not providing the required gasoline to the engine. Due to a faulty reading of a bad camshaft sensor, a larger amount of fuel is added into the engine than required, affecting fuel economy.

Transmission Shifting

- A car that has an automatic transmission causes error for gears changing due to a bad sensor. The solution is to turn off the engine and, after some time, start it again.

- The faulty data the ECM gets from the bad sensor prevents the shift solenoid from working and gear shifting. That is called Limp Mode, which protects the engine from damage through engine speed limitations

Engine Misfire

- signal of sensor control Fuel injectors also work with engine functions like spark control. But a damaged camshaft position sensor affects the engine to misfire, which produces vibration during acceleration.

- If the check engine light is on, it affects engine’s working, so check the car’s trouble codes. This error causes bad accelerations.

Gas Smell

- The bad sensor dumps unburned fuel into the exhaust system. It affects fuel efficiency and also causes black smoke from the tailpipe.

- This unburned fuel gas through the tailpipe produces a smell that can be dangerous.

Rough Idling

- camshaft position sensor is also due to rough idling. If the camshaft sensor is faulty, rough idle is due to bad combustion in the cylinder.

- It causes bad idle pump, EGR valve

How much does a camshaft position sensor cost to replace?

- The normal cost for replacing the camshaft position sensor is between $200 and $300.

- Labor costs range from $100 to $150, while parts are priced at $101 and $159.

- This cost does not cover fees and taxes, and also different locations have different prices.

How to Replace a Camshaft Position Sensor

Follow these points for replacing the camshaft position sensor.

- First, disconnect the negative battery wire.

- Then find the sensor, which can be on any side of the engine. that connected with two to three wires

- After finding, release the tab on the sensor to disconnect the wires on the sensor.

- Now unscrew the mounting bolt connected to the engine and sensor. That is an 8 mm or 10 mm bolt.

- Disconnect the damaged sensor. For installing a new sensor, use some engine oil sensor O-rings.

- Connect the new camshaft sensor and strongly connect with the mounting bolts.

- Now connect the wire sensor accurately; last, reconnect the negative battery terminal.

- Drive your car to check the working of the camshaft position sensor.

Where is the Camshaft Sensor Located?

- The location of the camshaft sensor is different based on the vehicle and engine. Advanced engines have a top connection of the camshaft.

- Some come with a block of engine and are also connected to the flywheel and transmission bell.

- • The car manual gives detailed instructions for the sensor. that helps to find and repair faults in a timely manner.

What happens if you don’t fix the camshaft sensor?

- If the camshaft is not working, it affects the starting of the vehicle. The bad working of the sensor affects data transmission to the ECM. Errors in ECM data affect fuel and spark movement; as a result, the engine does not work.

- During driving, an engine not working causes damage, so repair the sensor timely to avoid any damage.

FAQs

What is the function of the camshaft position sensor?

- camshaft position sensor: an electronic component that is part of the internal combustion engine for monitoring the rotational speed and position of the camshaft.

- ECM work on these details for fuel injector control, spark timing, and other engine functions

What tests can you perform on a camshaft position sensor?

- Perform testing for the two-wire sensor for voltage; when the meter leads are connected with the sensor points, move the metallic object over the sensor. If the meter finds voltage during the motion of the object on the sensor, that shows the sensor is working.