A knife gate valve is used for on/off applications and separates services in a system where a larger number of suspended solids exists. Knife gate valves are used in slurry handling with viscous, abrasive media, as well as corrosive materials.

This valve comes with low pressure losses in open conditions, the actuation process is simple, and it comes with a low-weight structure and low-cost applications. In this post,we will cover the detailed features of knife gate valves and practical applications. So let’s get started.

What Is a Knife Gate Valve?

- A knife gate valve is part of the applications for partitioning of systems where solid particles are in larger numbers.

- This valve is completely open in completely open condtions, causing low pressure losses, and its low weight makes its use easy.

- This knife gate valve structure features a sharp blade that cuts liquids effectively and performs well in harsh conditions.

- In wastewater applications where corrosion exists, a knife gate valve is used. Valve that is made for slurry medium, with a combination of a knife gate valve with acid-proof stainless steel, is best to use since it is not affected by corrosion and needs low maintenance

- This valve operates in both completely open and closed conditions, regulating flow when connected in certain applications.

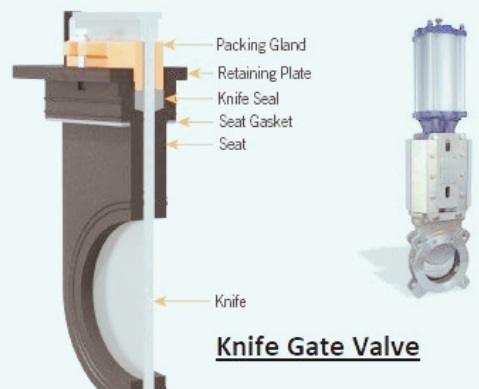

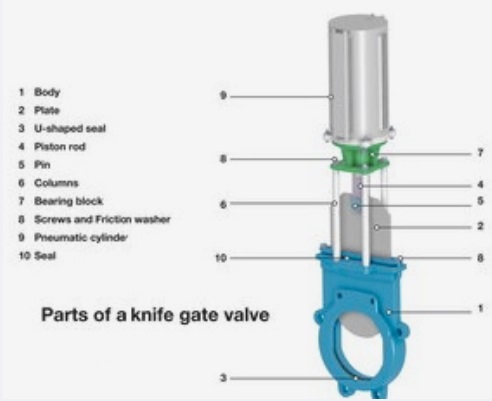

Parts of a knife gate valve

Gate

- A disk-shaped compound moves upward and downward in the valve body that opens or closes, allowing material.

Body

- It is the casing of a body that holds internal parts together and is used as a conduit for the movement of material.

Seats

- It is the surface that the gate makes a connection with in the valve-closed condition that provides a strong seal.

Bolts

- It is used on the external of the valve body and employed for clamping two halves of the valve structure together.

Packing

- The set seals used for controlling leakage over the gate and stem

Gland

- It holds the packing in position over the stem, which causes a a seal to avoid leakage.

Stem:

- It makes a connection gate with a handwheel and is used for raising and lowering the gate in the valve body.

Yoke

- It is larger in size, and the U-shaped part connected to the upper part of the valve is connected to the stem with a gate.

Stem Nut

- A nut-shaped part exists at the upper part of the stem and connects the stem with the actuator.

Hand Wheel or Actuator

- This part opens and closes the valve. It works with manual handwheels, hydraulic, pneumatic, and electro-hydraulic actuators.

How does a knife gate valve work?

- Knife valve used for controlling slurries, liquids, and other similar materials used in industries and other applications.

- This valve is reliable and durable, suitable for various industrial applications such as water treatment and power production.

- A knife gate valve comes with a stainless steel knife that controls medium flow upward or downward.

- gate connected with a handwheel or an actuator that closes or opens a valve.

- When the valve is in open conditions, the gate is upward, causing medium flow, and when the valve is in closed conditions, the gate moves downward to stop fluid flow.

- Knife gate valves are also operated through handwheels, hydraulic, electric, and electro-hydraulic actuators.

- It is used for bidirectional flow and operates under various temperature and pressure conditions

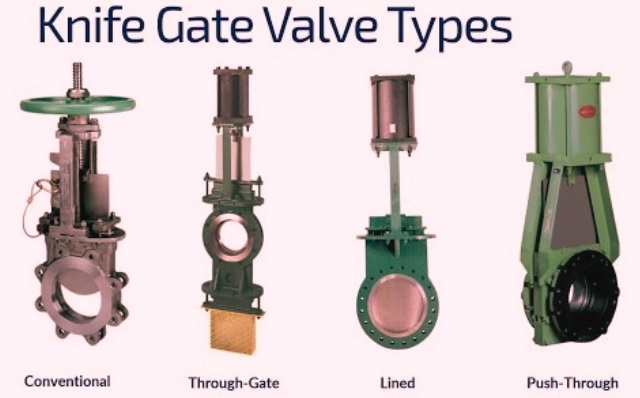

Knife Gate Valve Types

based on material

There are different types of materials used for gate valves, such as cast iron, ductile iron, nickel alloy steel, and stainless steel, which are commonly used.

Materials for the valve are selected based on fluid and temperature requirements. Different types of material gates are as follows:

Carbon steel knife gate valve:

- The carbon steel-made valve comes with high strength, hardness, and high impact. It is used for high-temperature and high-pressure conditions of plants.

Stainless steel knife gate valve

- Stainless steel is a high-cost material but is used for high corrosion resistance, good mechanical strength, low temperature resistance, and high resistance.

Lined valves

- It has resistance to chemicals, a stable nature for heat, and good mechanical features.

Types based on Stem Structure

Rising stems

- It is connected with a gate; when the valve operates, it moves up and down at the same time, which gives an indication of the valve locations. nut-like actuator movement over a threaded stem results from lifting and moving downward.

Non-rising stems:

- These are threaded to the gate; the stem is connected with the gate and moves with the actuator. motion concealed in the valve, define locations through directing the thread upward on the side of the ofstem.

- Non-rising stem is used where the vertical area is less, and also part of underground applications.

based on Connection Type

- The demand and accuracy of the valve give the direction of the connection end of the valve. Flanged-type ends are used for wafer-type knife gate valves and lug-type knife gate valves. gasket employed for sealing purposes

Sealing Method Types

Metal-seated knife gate valves:

- This valve is commonly used before applications of resilient-seated knife gate valves. For easy dipping, the valve lower performed through a conical wedge design and angular sealing of the metallic seated wedge.

- Due to tapping of sand and pebbles in the bore, the pipe was not purified of impurities, which caused proper flushing at the time of connection. that causes the metallic wedge to cause a low drop tight with passage time

Resilient seated knife gate

- This valve comes with a simple valve at a lower price that helps sand and pebbles easily pass. Rubber-made surface covers impurities that move through the valve in the off condition. While quality rubber compounds come with impurities and releases for valves in open condition. Rubber gets real conditions for making an original-shaped seal.

Differences between butterfly valves and knife gate valves

| Feature | Butterfly Valve |

Knife Gate Valve

|

| Valve Type | rotary motion valve comes disk rotation at 90 degrees |

it is a block valve that has a slab gate that moves in a linear way

|

| Flow Control component | The disk has the same diameter as the pipe bore |

Slab gate slides 90 degress to block the flow

|

| Motion | Rotates on the middle stem shaft |

Moves linearly

|

| Stem and Disk Assembly | Disk bored to stem; connected with bolts/pins, helping the disk to float for smooth sealing |

Gate stem connected to slab gate; cut through media

|

| Sealing Features | Elastomeric or rubber seat around valve body; clamp-ring control extrusion |

its used for on/off operations, seal control, abrasive, medium needed cutting action

|

| Body design | Wafer type: lug wafer, flanged, or threaded |

Robust body used for heavy-duty applications

|

| Applications | large flow,Low to medium pressure, slurries, liquids with suspended solids |

Heavy-duty, abrasive, or viscous fluids were cutting needed

|

| Moving Parts | Less moving parts, light weight, and compact design |

Robust, PART of demanding applications

|

Difference between knife gate valves and gate valves

- Wedge-type gate valves and knife gate valves are used for on/off applications that make the valve completely open and closed.

- These valves are not used for flow regulation since when fluid applies to the closed gate, it causes vibration, and cavitation affects the seat and body.

- These two valves are made for opening and closing applications in a slow way to minimize water hammering.

- The knife gate valve comes with a sharpened disc for controlling easy movement of the slurry medium. A knife valve comes in a smaller face-to-face length than a gate valve, which is a larger size.

- knife gate valve is lower in weight than a gate valve. knife gate valves used for wastewater treatment plants, chemical plants, and cement plants; gate valves used for drinking water supplies; and water pump stations.

- Both have common applications, such as slurries and heavy oils. Non-flammable viscous fluids, wastewater, and clean water

knife gate valves

- used for different applications. that are as

HVAC Systems

- It is part of the ventilation, heating, and AC system that regulates water flow and some other liquids.

Industries

- It is used for controlling liquid, gas, and powder movement. It is part of the food, beverage, and chemical industries and also used for cement plants and pulp mills.

Pneumatic Conveying

- It controls material flow in conveying systems like fertilizer and cement industries.

Water and Sewage

- It is part of water treatment plants and sewage treatment plants that control water flow and other fluids.

- It is used for applications for providing off-conditioned environments, such as in high-pressure and high-temperature conditions.

Advantages of Knife Gate Valves

- It activated easily through pneumatic, electrical, and mechanical ways.

- It is lightweight and easy to carry, with easy installation, storage, and simple maintenance.

- It is a low-cost valve and is used for non-volatile, non-flammable viscous fluids.

- It opens and closes slowly to protect against water hammer.

People also ask

What is the function of the knife gate valve?

- knife gate valve used for harsh conditions comes with a sharpened blade for cutting heavy liquids. It is good to use for wastewater applications where corrosion exists.

What are the different types of gate valves?

- The main types of gate valves are parallel and wedge-shaped. A wedge-shaped gate valve comes with two inclined seats and an inclined gate that is misaligned with the seats.

What is the process of a knife gate valve?

- Knife gate valves work through actuators connected for opening and closing the valve; the piston gets pressed and moves the blade upward and downward. Gate work is effective since the blade retracts open conditions, causing movement of flow.

Read also